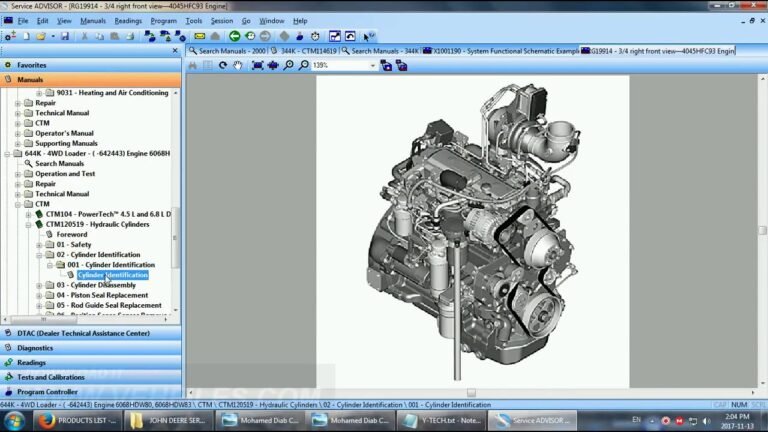

The Nissan Navara D40 OEM Service Manual is a complete guide for maintaining, diagnosing, and repairing your vehicle. This manual provides detailed wiring diagrams, diagnostic procedures, and comprehensive repair instructions, making it an essential tool for both professional mechanics and DIY enthusiasts. Whether you’re addressing electrical issues or performing complex repairs, this workshop guide ensures that your Nissan Navara D40 is serviced to factory standards.

Key Features:

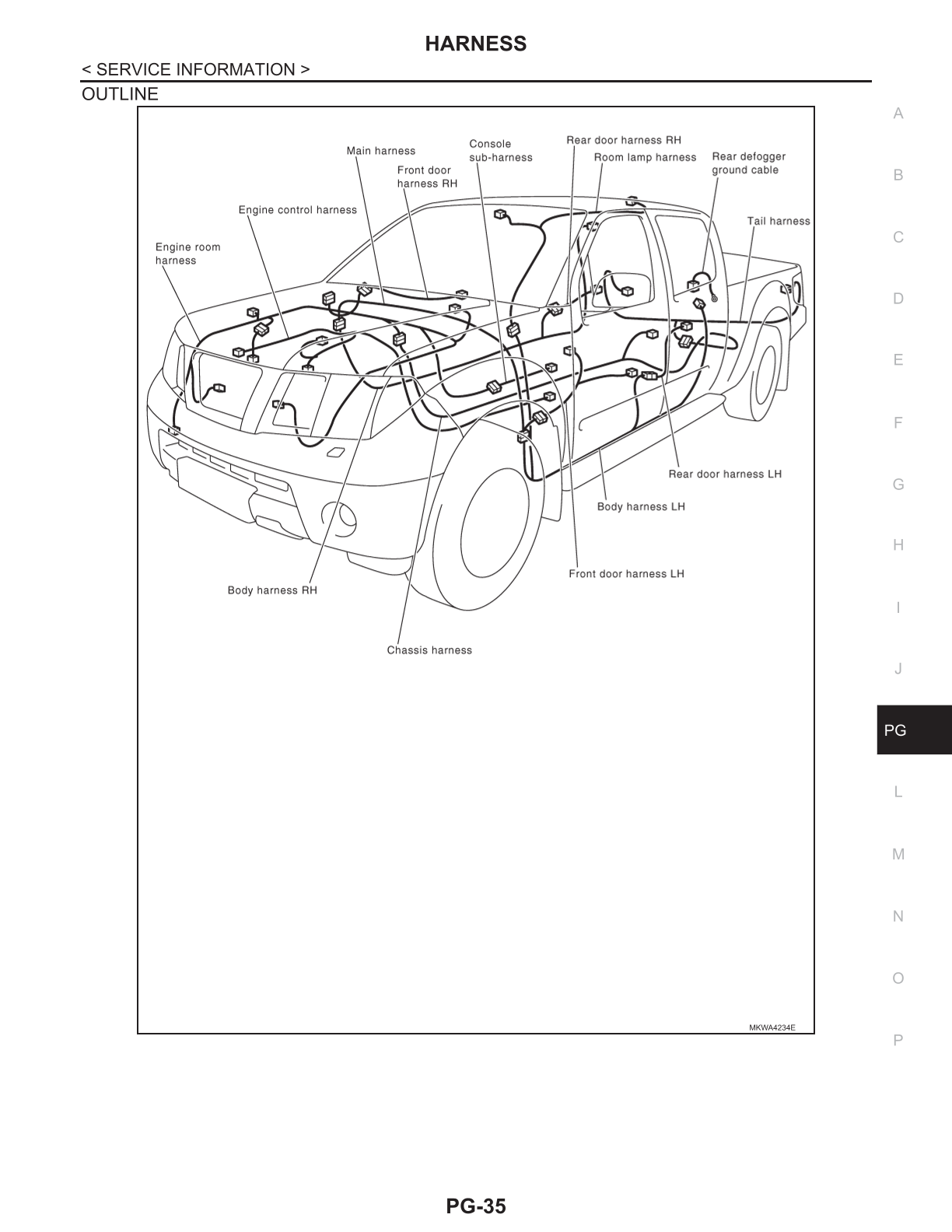

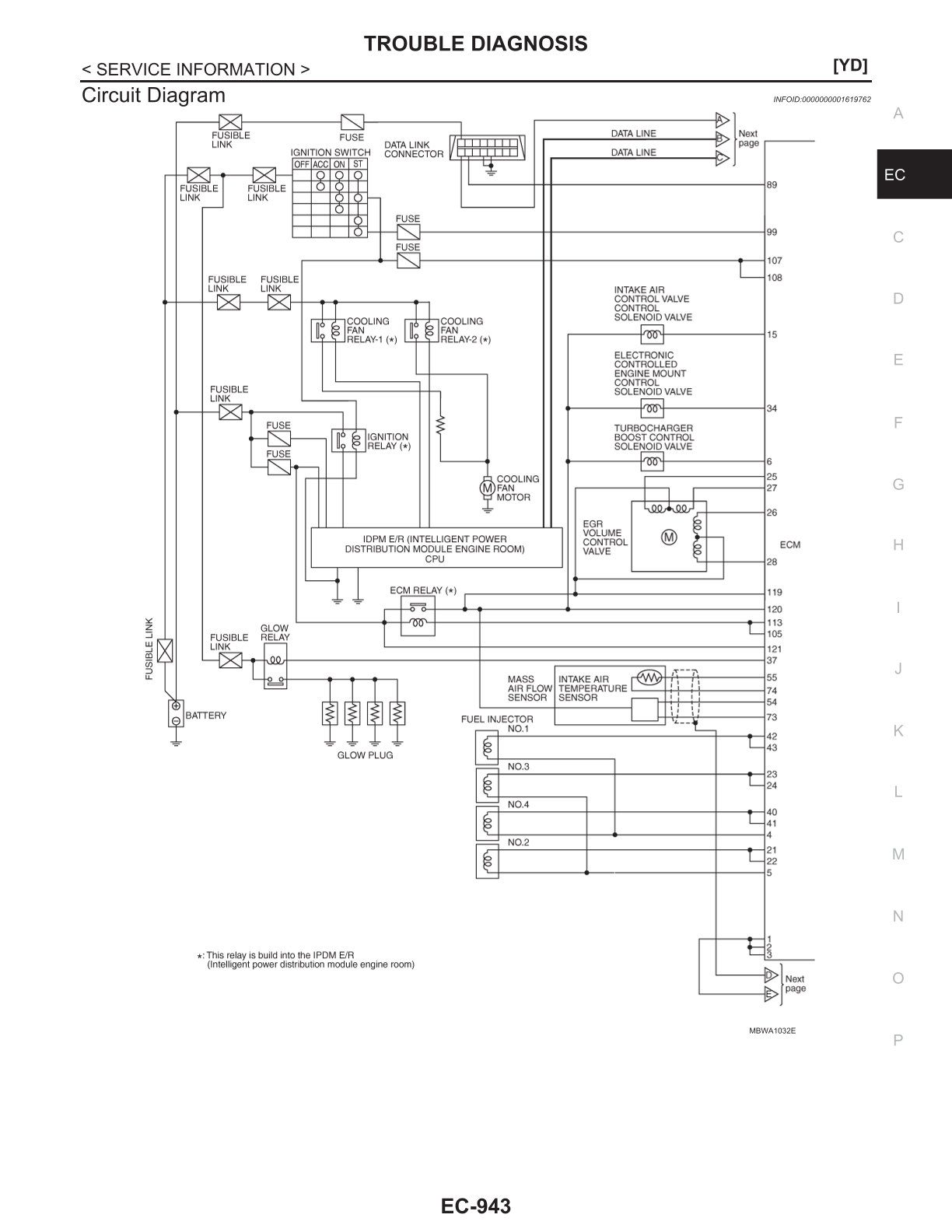

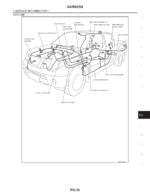

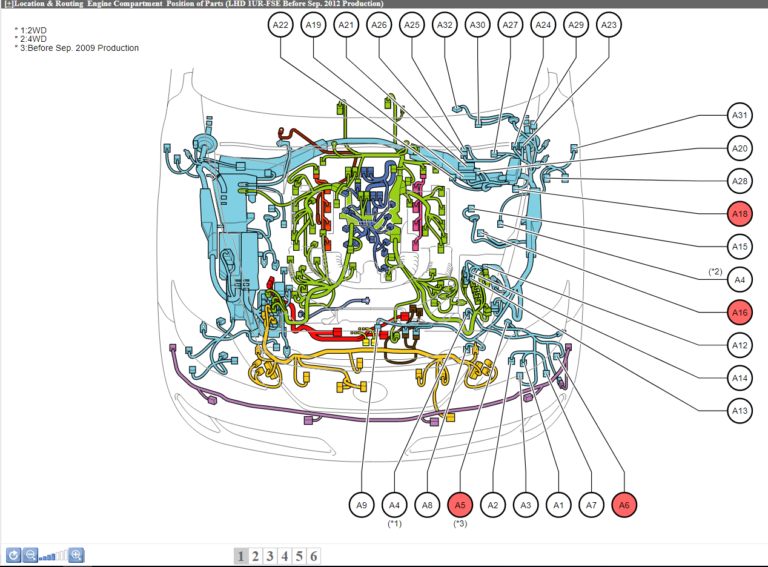

- Detailed Wiring Diagrams: Complete electrical schematics for all systems, helping you troubleshoot and repair electrical issues accurately.

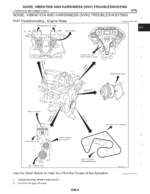

- Comprehensive Diagnostics: Step-by-step diagnostic procedures to identify and resolve mechanical and electrical problems.

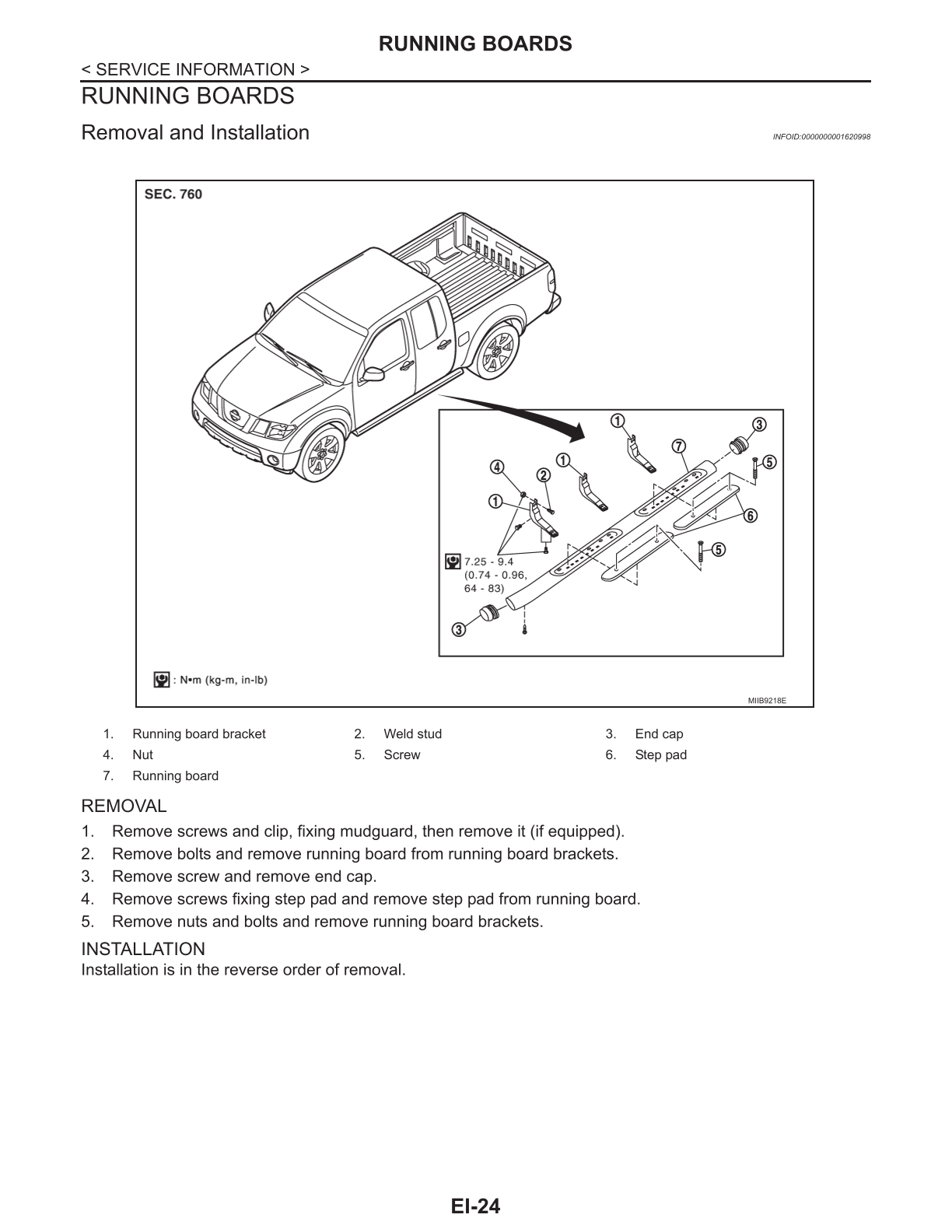

- OEM-Grade Repair Instructions: Detailed repair guidance for everything from engine maintenance to transmission and suspension repairs, ensuring all work is done to Nissan’s original specifications.

- Troubleshooting Guides: Expert tips on diagnosing common issues and resolving them effectively to keep your Navara running smoothly.

- User-Friendly Layout: Organized format with clear illustrations and step-by-step instructions, making repairs straightforward and easy to follow.

Format: PDF

Pages: 3444

Delivery: The download link will be promptly delivered to your email upon completing the checkout process.

- ACC

- ACCELERATOR CONTROL SYSTEM

- SERVICE INFORMATION

- ACCELERATOR CONTROL SYSTEM

- Component

- Removal and Installation

- REMOVAL

- INSTALLATION

- INSPECTION AFTER INSTALLATION

- ACS

- AUTO CRUISE CONTROL SYSTEM

- ASCD

- SERVICE INFORMATION

- AUTOMATIC SPEED CONTROL DEVICE (ASCD)

- Description

- AT

- AUTOMATIC TRANSMISSION

- SERVICE INFORMATION

- INDEX FOR DTC

- Alphabetical Index

- DTC No. Index

- PRECAUTIONS

- Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER"

- Precaution

- PREPARATION

- Special Service Tool

- Commercial Service Tool

- A/T FLUID

- Changing A/T Fluid

- Checking A/T Fluid

- A/T CONTROL SYSTEM

- Cross-Sectional View (YD25DDTi Models for 2WD)

- Cross-Sectional View (VQ40DE Models for 2WD)

- Cross-Sectional View (YD25DDTi Models for 4WD)

- Cross-Sectional View (VQ40DE Models for 4WD)

- Shift Mechanism

- CONSTRUCTION

- FUNCTION OF CLUTCH AND BRAKE

- CLUTCH AND BAND CHART

- POWER TRANSMISSION

- “N” Position

- “P” Position

- “D”, “3” and “2” Positions 1st Gear

- “1” Position 1st Gear

- “D” and “3” Positions 2nd Gear

- “2” and “1” Positions 2nd Gear

- “D” and “3” Positions 3rd Gear

- “D” Position 4th Gear

- “D” Position 5th Gear

- “R” position

- TCM Function

- CONTROL SYSTEM OUTLINE

- CONTROL SYSTEM DIAGRAM

- CAN Communication

- SYSTEM DESCRIPTION

- Input/Output Signal of TCM

- Line Pressure Control

- LINE PRESSURE CONTROL IS BASED ON THE TCM LINE PRESSURE CHARACTERISTIC PATTERN

- Normal Control

- Back-up Control (Engine Brake)

- During Shift Change

- At Low Fluid Temperature

- Shift Control

- SHIFT CHANGE

- Shift Change System Diagram

- Lock-up Control

- TORQUE CONVERTER CLUTCH CONTROL VALVE CONTROL

- Lock-up Control System Diagram

- Lock-up Released

- Lock-up Applied

- SMOOTH LOCK-UP CONTROL

- Half-clutched State

- Engine Brake Control

- Control Valve

- FUNCTION OF CONTROL VALVE

- FUNCTION OF PRESSURE SWITCH

- TROUBLE DIAGNOSIS

- DTC Inspection Priority Chart

- Fail-Safe

- FAIL-SAFE FUNCTION

- Vehicle Speed Sensor

- Accelerator Pedal Position Sensor

- Throttle Position Sensor (VQ40DE Model Only)

- PNP Switch

- Starter Relay

- A/T Interlock

- A/T 1st Engine Braking

- Line Pressure Solenoid

- Torque Converter Clutch Solenoid

- Low Coast Brake Solenoid

- Input Clutch Solenoid

- Direct Clutch Solenoid

- Front Brake Solenoid

- High and Low Reverse Clutch Solenoid

- Turbine Revolution Sensor 1 or 2

- How to Perform Trouble Diagnosis for Quick and Accurate Repair

- INTRODUCTION

- WORK FLOW

- Work Flow Chart

- DIAGNOSTIC WORKSHEET

- Information from Customer

- Diagnostic Worksheet Chart

- A/T Electrical Parts Location

- Circuit Diagram

- Inspections Before Trouble Diagnosis

- A/T FLUID CHECK

- A/T Fluid Leakage and A/T Fluid Level Check

- A/T Fluid Condition Check

- STALL TEST

- Stall Test Procedure

- Judgement of Stall Test

- LINE PRESSURE TEST

- Line Pressure Test Port

- Line Pressure Test Procedure

- Line Pressure

- Judgement of Line Pressure Test

- Road Test

- DESCRIPTION

- CHECK BEFORE ENGINE STARTED

- CHECK AT IDLE

- CRUISE TEST-PART 1

- CRUISE TEST-PART 2

- CRUISE TEST-PART 3

- Vehicle Speed at Which Gear Shifting Occurs

- 2WD MODELS

- 4WD MODELS

- Vehicle Speed at Which Lock-up Occurs/Releases

- 2WD MODELS

- 4WD MODELS

- Symptom Chart

- TCM Input/Output Signal Reference Value

- A/T ASSEMBLY HARNESS CONNECTOR TERMINAL LAYOUT

- TCM INSPECTION TABLE

- CONSULT-III Function (TRANSMISSION)

- FUNCTION

- CONSULT-III REFERENCE VALUE

- SELF-DIAGNOSTIC RESULT MODE

- Display Items List

- DATA MONITOR MODE

- Display Items List

- DTC WORK SUPPORT MODE

- Display Items List

- Diagnosis Procedure without CONSULT-III

- TCM SELF-DIAGNOSTIC PROCEDURE (WITHOUT CONSULT-III)

- Description

- Diagnostic Procedure

- Judgement Self-diagnosis Code

- Erase Self-diagnosis

- DTC U1000 CAN COMMUNICATION LINE

- Description

- On Board Diagnosis Logic

- Possible Cause

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITHOUT CONSULT-III

- Wiring Diagram - AT - CAN

- Diagnosis Procedure

- DTC P0615 START SIGNAL CIRCUIT

- Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- Possible Cause

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITHOUT CONSULT-III

- Wiring Diagram - AT - STSIG

- Diagnosis Procedure

- DTC P0700 TCM

- Description

- On Board Diagnosis Logic

- Possible Cause

- DTC Confirmation Procedure

- WITH CONSULT-III

- Diagnosis Procedure

- DTC P0705 PARK/NEUTRAL POSITION SWITCH

- Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- Possible Cause

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITHOUT CONSULT-III

- Wiring Diagram - AT - PNP/SW

- Diagnosis Procedure

- DTC P0720 VEHICLE SPEED SENSOR A/T (REVOLUTION SENSOR)

- Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- Possible Cause

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITHOUT CONSULT-III

- Wiring Diagram - AT - VSSA/T

- Diagnosis Procedure

- DTC P0725 ENGINE SPEED SIGNAL

- Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- Possible Cause

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITHOUT CONSULT-III

- Diagnosis Procedure

- DTC P0740 TORQUE CONVERTER CLUTCH SOLENOID VALVE

- Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- Possible Cause

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITHOUT CONSULT-III

- Diagnosis Procedure

- DTC P0744 A/T TCC S/V FUNCTION (LOCK-UP)

- Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- Possible Cause

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITHOUT CONSULT-III

- Diagnosis Procedure

- DTC P0745 LINE PRESSURE SOLENOID VALVE

- Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- Possible Cause

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITHOUT CONSULT-III

- Diagnosis Procedure

- DTC P1705 THROTTLE POSITION SENSOR

- Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- Possible Cause

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITHOUT CONSULT-III

- Diagnosis Procedure

- DTC P1710 A/T FLUID TEMPERATURE SENSOR CIRCUIT

- Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- Possible Cause

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITHOUT CONSULT-III

- Wiring Diagram - AT - FTS

- Diagnosis Procedure

- Component Inspection

- A/T FLUID TEMPERATURE SENSOR 1

- A/T FLUID TEMPERATURE SENSOR 2

- DTC P1716 TURBINE REVOLUTION SENSOR

- Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- Possible Cause

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITHOUT CONSULT-III

- Diagnosis Procedure

- DTC P1721 VEHICLE SPEED SENSOR MTR

- Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- Possible Cause

- DTC Confirmation Procedure

- WITH CONSULT-III

- Diagnosis Procedure

- DTC P1730 A/T INTERLOCK

- Description

- On Board Diagnosis Logic

- Possible Cause

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITHOUT CONSULT-III

- Judgement of A/T Interlock

- A/T INTERLOCK COUPLING PATTERN TABLE

- Diagnosis Procedure

- DTC P1731 A/T 1ST ENGINE BRAKING

- Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- Possible Cause

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITHOUT CONSULT-III

- Diagnosis Procedure

- DTC P1752 INPUT CLUTCH SOLENOID VALVE

- Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- Possible Cause

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITHOUT CONSULT-III

- Diagnosis Procedure

- DTC P1754 INPUT CLUTCH SOLENOID VALVE FUNCTION

- Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- Possible Cause

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITHOUT CONSULT-III

- Diagnosis Procedure

- DTC P1757 FRONT BRAKE SOLENOID VALVE

- Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- Possible Cause

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITHOUT CONSULT-III

- Diagnosis Procedure

- DTC P1759 FRONT BRAKE SOLENOID VALVE FUNCTION

- Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- Possible Cause

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITHOUT CONSULT-III

- Diagnosis Procedure

- DTC P1762 DIRECT CLUTCH SOLENOID VALVE

- Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- Possible Cause

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITHOUT CONSULT-III

- Diagnosis Procedure

- DTC P1764 DIRECT CLUTCH SOLENOID VALVE FUNCTION

- Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- Possible Cause

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITHOUT CONSULT-III

- Diagnosis Procedure

- DTC P1767 HIGH AND LOW REVERSE CLUTCH SOLENOID VALVE

- Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- Possible Cause

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITHOUT CONSULT-III

- Diagnosis Procedure

- DTC P1769 HIGH AND LOW REVERSE CLUTCH SOLENOID VALVE FUNCTION

- Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- Possible Cause

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITHOUT CONSULT-III

- Diagnosis Procedure

- DTC P1772 LOW COAST BRAKE SOLENOID VALVE

- Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- Possible Cause

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITHOUT CONSULT-III

- Diagnosis Procedure

- DTC P1774 LOW COAST BRAKE SOLENOID VALVE FUNCTION

- Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- Possible Cause

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITHOUT CONSULT-III

- Diagnosis Procedure

- DTC P1841 ATF PRESSURE SWITCH 1

- Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- Possible Cause

- DTC Confirmation Procedure

- WITH CONSULT-III

- Diagnosis Procedure

- DTC P1843 ATF PRESSURE SWITCH 3

- Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- Possible Cause

- DTC Confirmation Procedure

- WITH CONSULT-III

- Diagnosis Procedure

- DTC P1845 ATF PRESSURE SWITCH 5

- Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- Possible Cause

- DTC Confirmation Procedure

- WITH CONSULT-III

- Diagnosis Procedure

- DTC P1846 ATF PRESSURE SWITCH 6

- Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- Possible Cause

- DTC Confirmation Procedure

- WITH CONSULT-III

- Diagnosis Procedure

- MAIN POWER SUPPLY AND GROUND CIRCUIT

- Wiring Diagram - AT - MAIN

- Diagnosis Procedure

- CLOSED THROTTLE POSITION AND WIDE OPEN THROTTLE POSITION CIRCUIT

- CONSULT-III Reference Value in Data Monitor Mode

- Diagnosis Procedure

- BRAKE SIGNAL CIRCUIT

- CONSULT-III Reference Value in Data Monitor Mode

- Diagnosis Procedure

- 1ST POSITION SWITCH

- CONSULT-III Reference Value in Data Monitor Mode

- Diagnosis Procedure

- OVERDRIVE CONTROL SWITCH

- CONSULT-III Reference Value in Data Monitor Mode

- Diagnosis Procedure

- TROUBLE DIAGNOSIS FOR SYMPTOMS

- Wiring Diagram - AT - NONDTC

- OD OFF Indicator Lamp Does Not Come On

- SYMPTOM:

- DIAGNOSTIC PROCEDURE

- Engine Cannot Be Started in "P" or "N" Position

- SYMPTOM:

- DIAGNOSTIC PROCEDURE

- In "P" Position, Vehicle Moves When Pushed

- SYMPTOM:

- DIAGNOSTIC PROCEDURE

- In "N" Position, Vehicle Moves

- SYMPTOM:

- DIAGNOSTIC PROCEDURE

- Large Shock ("N" to "D" Position)

- SYMPTOM:

- DIAGNOSTIC PROCEDURE

- Vehicle Does Not Creep Backward in "R" Position

- SYMPTOM:

- DIAGNOSTIC PROCEDURE

- Vehicle Does Not Creep Forward in "D" Position

- SYMPTOM:

- DIAGNOSTIC PROCEDURE

- Vehicle Cannot Be Started from D1

- SYMPTOM:

- DIAGNOSTIC PROCEDURE

- A/T Does Not Shift: D1Æ D2

- SYMPTOM:

- DIAGNOSTIC PROCEDURE

- A/T Does Not Shift: D2Æ D3

- SYMPTOM:

- DIAGNOSTIC PROCEDURE

- A/T Does Not Shift: D3Æ D4

- SYMPTOM:

- DIAGNOSTIC PROCEDURE

- A/T Does Not Shift: D4Æ D5

- SYMPTOM:

- DIAGNOSTIC PROCEDURE

- A/T Does Not Perform Lock-up

- SYMPTOM:

- DIAGNOSTIC PROCEDURE

- A/T Does Not Hold Lock-up Condition

- SYMPTOM:

- DIAGNOSTIC PROCEDURE

- Lock-up Is Not Released

- SYMPTOM:

- DIAGNOSTIC PROCEDURE

- Engine Speed Does Not Return to Idle

- SYMPTOM:

- DIAGNOSTIC PROCEDURE

- A/T Does Not Shift: 5th Gear Æ 4th Gear

- SYMPTOM:

- DIAGNOSTIC PROCEDURE

- A/T Does Not Shift: 4th Gear Æ 3rd Gear

- SYMPTOM:

- DIAGNOSTIC PROCEDURE

- A/T Does Not Shift: 3rd Gear Æ 2nd Gear

- SYMPTOM:

- DIAGNOSTIC PROCEDURE

- A/T Does Not Shift: 2nd Gear Æ 1st Gear

- SYMPTOM:

- DIAGNOSTIC PROCEDURE

- Vehicle Does Not Decelerate by Engine Brake

- SYMPTOM:

- DIAGNOSTIC PROCEDURE

- SHIFT CONTROL SYSTEM

- Control Device Removal and Installation

- COMPONENTS

- REMOVAL

- INSTALLATION

- Control Cable Removal and Installation

- COMPONENTS

- REMOVAL

- INSTALLATION

- Adjustment of A/T Position

- Checking of A/T Position

- A/T SHIFT LOCK SYSTEM

- Description

- Shift Lock System Electrical Parts Location

- Wiring Diagram - A/T - SHIFT

- Diagnosis Procedure

- KEY INTERLOCK CABLE

- Removal and Installation

- COMPONENTS

- REMOVAL

- INSTALLATION

- ON-VEHICLE SERVICE

- Control Valve with TCM and A/T Fluid Temperature Sensor 2

- COMPONENTS

- CONTROL VALVE WITH TCM REMOVAL AND INSTALLATION

- Removal

- Installation

- A/T FLUID TEMPERATURE SENSOR 2 REMOVAL AND INSTALLATION

- Removal

- Installation

- Parking Component (2WD Models Only)

- REMOVAL AND INSTALLATION

- Components

- Removal

- Inspection

- Installation

- Rear Oil Seal

- REMOVAL AND INSTALLATION

- Removal

- Installation

- Revolution Sensor Component (2WD Models Only)

- REMOVAL AND INSTALLATION

- Components

- Removal

- Installation

- AIR BREATHER HOSE

- Removal and Installation

- YD25DDTI MODELS

- VQ40DE MODELS

- A/T FLUID COOLER

- Removal and Installation

- COMPONENTS

- REMOVAL

- INSTALLATION

- TRANSMISSION ASSEMBLY

- Removal and Installation (YD25DDTi Models)

- COMPONENTS

- REMOVAL

- INSPECTION

- Installation and Inspection of Torque Converter

- INSTALLATION

- Removal and Installation (VQ40DE Models)

- COMPONENTS

- REMOVAL

- INSPECTION

- Installation and Inspection of Torque Converter

- INSTALLATION

- OVERHAUL

- Component

- Oil Channel

- Location of Adjusting Shims, Needle Bearings, Thrust Washers and Snap Rings

- DISASSEMBLY

- Disassembly

- REPAIR FOR COMPONENT PARTS

- Oil Pump

- COMPONENTS

- DISASSEMBLY

- ASSEMBLY

- Front Sun Gear, 3rd One-Way Clutch

- COMPONENTS

- DISASSEMBLY

- INSPECTION

- 3rd One-way Clutch

- Front Sun Gear Snap Ring

- Front Sun Gear

- ASSEMBLY

- Front Carrier, Input Clutch, Rear Internal Gear

- COMPONENTS

- DISASSEMBLY

- INSPECTION

- Front Carrier Snap Ring

- Input Clutch Snap Ring

- Input Clutch Drum

- Input Clutch Drive Plates

- Input Clutch Retaining Plate and Driven Plates

- Front Carrier

- Rear Internal Gear

- ASSEMBLY

- Mid Sun Gear, Rear Sun Gear, High and Low Reverse Clutch Hub

- COMPONENTS

- DISASSEMBLY

- INSPECTION

- High and Low Reverse Clutch Hub Snap Ring, Rear Sun Gear Snap Ring

- 1st One-way Clutch

- Mid Sun Gear

- Rear Sun Gear

- High and Low Reverse Clutch Hub

- ASSEMBLY

- High and Low Reverse Clutch

- COMPONENTS

- DISASSEMBLY

- INSPECTION

- High and Low Reverse Clutch Snap Ring

- High and Low Reverse Clutch Drive Plates

- High and Low Reverse Clutch Retaining Plate and Driven Plates

- ASSEMBLY

- Direct Clutch

- COMPONENTS

- DISASSEMBLY

- INSPECTION

- Direct Clutch Snap Rings

- Direct Clutch Drive Plates

- Direct Clutch Retaining Plate and Driven Plates

- ASSEMBLY

- ASSEMBLY

- Assembly (1)

- Adjustment

- TOTAL END PLAY

- Assembly (2)

- SERVICE DATA AND SPECIFICATIONS (SDS)

- General Specification

- Stall Speed

- Line Pressure

- Vehicle Speed at Which Gear Shifting Occurs

- 2WD MODELS

- 4WD MODELS

- Vehicle Speed at Which Lock-up Occurs/Releases

- 2WD MODELS

- 4WD MODELS

- A/T Fluid Temperature Sensor

- Vehicle Speed Sensor A/T (Revolution Sensor)

- Turbine Revolution Sensor

- Reverse Brake

- Total End Play

- AV

- AUDIO-VISUAL SYSTEM

- SERVICE INFORMATION

- PRECAUTIONS

- Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER"

- PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

- SYSTEM DESCRIPTION

- System Functions

- Component Description

- AUDIO UNIT

- Component Parts Location

- Location of Antenna

- Wiring Diagram - AUDIO -

- Wiring Diagram - AUDIO - (VQ engine: VIN >VSKC**D40A0037688)

- TERMINALS AND REFERENCE VALUE

- Audio Unit

- Audio Unit (VQ Engine: VIN >VSKC**D40A0037688)

- TROUBLE DIAGNOSIS

- Audio Trouble Diagnosis

- MALFUNCTION WITH RADIO, TAPE AND CD

- FOR RADIO ONLY

- FOR CASSETTE PLAYER ONLY

- FOR CD ONLY

- Noise Inspection

- TYPE OF NOISE AND POSSIBLE CAUSE

- REMOVAL AND INSTALLATION

- Audio Unit

- REMOVAL

- INSTALLATION

- Front Door Speaker

- REMOVAL

- INSTALLATION

- Rear Door Speaker

- REMOVAL

- INSTALLATION

- Tweeter

- REMOVAL

- INSTALLATION

- Roof Antenna

- REMOVAL

- INSTALLATION

- BCS

- BODY CONTROL SYSTEM

- SERVICE INFORMATION

- DTC INDEX

- U1000

- PRECAUTIONS

- Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER"

- BCM (BODY CONTROL MODULE)

- System Description

- BCM FUNCTION

- COMBINATION SWITCH READING FUNCTION

- Description

- Operation Description

- BCM - Operation Table of Combination Switch

- Example Operation: (When Lighting Switch 1st Position Turned ON)

- Operation Mode

- CAN COMMUNICATION CONTROL

- BCM STATUS CONTROL

- SYSTEMS CONTROLLED BY BCM DIRECTLY

- SYSTEMS CONTROLLED BY BCM AND IPDM E/R

- SYSTEMS CONTROLLED BY BCM AND COMBINATION METER

- MAJOR COMPONENTS AND CONTROL SYSTEM

- CAN Communication System Description

- Schematic

- CONSULT-III Function (BCM)

- SYSTEM APPLICATION

- WORK SUPPORT

- Display Item List

- SELF-DIAGNOSTIC RESULT

- Configuration (BCM)

- Configuration Procedure

- Configuration list

- U1000 CAN Communication Circuit

- Removal and Installation of BCM

- REMOVAL

- INSTALLATION

- BL

- BODY, LOCK & SECURITY SYSTEM

- SERVICE INFORMATION

- DTC INDEX

- ECM P1610-P1616

- PRECAUTIONS

- Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER"

- Precaution for procedures with out cowl top cover

- Precaution for Work

- PREPARATION

- Commercial Service Tool

- SQUEAK AND RATTLE TROUBLE DIAGNOSIS

- Work Flow

- CUSTOMER INTERVIEW

- DUPLICATE THE NOISE AND TEST DRIVE

- CHECK RELATED SERVICE BULLETINS

- LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

- REPAIR THE CAUSE

- CONFIRM THE REPAIR

- Generic Squeak and Rattle Troubleshooting

- INSTRUMENT PANEL

- CENTER CONSOLE

- DOORS

- TRUNK

- SUNROOF/HEADLINING

- SEATS

- UNDERHOOD

- Diagnostic Worksheet

- HOOD

- Fitting Adjustment

- LONGITUDINAL AND LATERAL CLEARANCE ADJUSTMENT

- FRONT END HEIGHT ADJUSTMENT

- SURFACE HEIGHT ADJUSTMENT

- Removal and Installation of Hood Assembly

- REMOVAL

- INSTALLATION

- Removal and Installation of Hood Hinge

- REMOVAL

- INSTALLATION

- Removal and Installation of Hood Lock Control

- REMOVAL

- INSTALLATION

- Hood Lock Control Inspection

- RADIATOR CORE SUPPORT

- Removal and Installation

- REMOVAL

- INSTALLATION

- FRONT FENDER

- Removal and Installation

- REMOVAL

- INSTALLATION

- POWER DOOR LOCK SYSTEM

- Component Parts and Harness Connector Location

- System Description

- OUTLINE

- Function Available by Operating the Door Lock/Unlock Switch

- Door Lock Warning Function

- Key Reminder Function

- Door Lock/Unlock Switch Indicator

- CAN Communication System Description

- CAN Communication Unit

- Schematic

- Wiring Diagram - D/LOCK -

- Terminal and Reference Value for BCM

- CONSULT-III Function (BCM)

- CONSULT-III APPLICATION ITEMS

- Work Support

- Data Monitor

- Active Test

- Work Flow

- Trouble Diagnosis Chart by Symptom

- Check Power Supply and Ground Circuit

- Check Door Switch

- CHECK DOOR SWITCH

- Check Key Switch

- Check Door Key Cylinder Switch

- Check Front Door Lock Actuator (Driver Side)

- Check Front Door Lock Actuator (Passenger Side)

- Check Front Door Lock Actuator Switch

- Check Rear Door Lock Actuator LH

- Check Rear Door Lock Actuator RH

- Check RH and LH Rear Door Lock Actuator Switch

- Check Door Lock/Unlock Switch

- Check Door Lock/Unlock Switch Indicator

- MULTI-REMOTE CONTROL SYSTEM

- Component Parts and Harness Connector Location

- System Description

- INPUTS

- OPERATING PROCEDURE

- Power Door Lock Operation

- Hazard Reminder

- Auto Re-lock Function

- Room Lamp Operation

- CAN Communication System Description

- Wiring Diagram - MULTI -

- Terminal and Reference Value for BCM

- CONSULT-III Function (BCM)

- CONSULT-III Application Item

- “MULTI REMOTE ENT”

- Data Monitor

- Active Test

- Work Support

- Trouble Diagnosis Procedure

- Trouble Diagnosis Chart by Symptom

- Check Keyfob Battery and Function

- Check ACC Switch

- Check Door Switch

- CHECK DOOR SWITCH

- Check Key Switch

- Check Hazard Function

- Check Map Lamp and Ignition Keyhole Illumination Function

- ID Code Entry Procedure

- KEYFOB ID SET UP

- Remote Controller Battery Replacement

- DOOR

- Fitting Adjustment

- FRONT DOOR

- Longitudinal Clearance and Surface Height Adjustment at Front End

- REAR DOOR

- Longitudinal Clearance and Surface Height Adjustment at Front End

- STRIKER ADJUSTMENT

- Removal and Installation of Front Door

- REMOVAL

- INSTALLATION

- Removal and Installation of Rear Door

- REMOVAL

- INSTALLATION

- Removal and Installation of Door Weather-strip

- REMOVAL

- INSTALLATION

- FRONT DOOR LOCK

- Removal and Installation

- REMOVAL

- INSTALLATION

- REAR DOOR LOCK

- Removal and Installation of Rear Door Lock

- REMOVAL

- INSTALLATION

- TAIL GATE

- Component Parts Location

- FUEL FILLER LID OPENER

- Removal and Installation of Fuel Filler Lid

- REMOVAL

- INSTALLATION

- Removal and Installation of Fuel Lid Lock Striker

- REMOVAL

- INSTALLATION

- NATS(Nissan Anti-Theft System)

- Component Parts and Harness Connector Location

- System Description

- System Composition

- ECM Re-communicating Function

- Wiring Diagram - NATS -

- Terminal and Reference Value for BCM

- CONSULT-III Function

- CONSULT-III DIAGNOSTIC TEST MODE FUNCTION

- NATS SELF-DIAGNOSTIC RESULTS ITEM CHART

- Trouble Diagnosis Procedure

- WORK FLOW

- Trouble Diagnosis

- SYMPTOM MATRIX CHART 1

- SYMPTOM MATRIX CHART 2

- Diagnosis Procedure 1

- Diagnosis Procedure 2

- Diagnosis Procedure 3

- Diagnosis Procedure 4

- Diagnosis Procedure 5

- Diagnosis Procedure 6

- Removal and Installation of NATS Antenna Amp

- REMOVAL

- INSTALLATION

- CAB AND REAR BODY

- Body Mounting

- BODY REPAIR

- Body Alignment

- DESCRIPTION

- ENGINE COMPARTMENT

- Measurement

- Measurement Points

- UNDERBODY

- Measurement

- Measurement Points

- PASSENGER COMPARTMENT

- Measurement (King Cab)

- Measurement (Double Cab)

- Measurement Points

- REAR BODY

- Measurement

- Measurement Points

- PICKUP BED

- Measurement (King Cab)

- Measurement (Double Cab)

- Measurement Points

- BR

- BRAKE SYSTEM

- SERVICE INFORMATION

- PRECAUTIONS

- Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER"

- Precaution for Brake System

- PREPARATION

- Special Service Tool

- Commercial Service Tool

- NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

- NVH Troubleshooting Chart

- BRAKE PEDAL

- Inspection and Adjustment

- INSPECTION

- ADJUSTMENT

- Removal and Installation

- COMPONENTS

- REMOVAL

- INSPECTION AFTER REMOVAL

- INSTALLATION

- BRAKE FLUID

- On Board Inspection

- CHECKING BRAKE FLUID LEVEL

- Drain and Refill

- Bleeding Brake System

- BRAKE TUBE AND HOSE

- Hydraulic Circuit

- Removal and Installation of Front Brake Tube and Brake Hose

- REMOVAL

- INSTALLATION

- Removal and Installation of Rear Brake Tube and Brake Hose

- REMOVAL

- INSTALLATION

- Inspection after Installation

- LOAD SENSING VALVE

- Removal and Installation

- REMOVAL

- INSTALLATION

- Inspection

- INSPECTION

- BRAKE MASTER CYLINDER

- On-Board Inspection

- LEAK INSPECTION

- Removal and Installation

- REMOVAL

- INSTALLATION

- Component

- Disassembly and Assembly

- DISASSEMBLY

- ASSEMBLY

- BRAKE BOOSTER

- On-Vehicle Service

- OPERATING CHECK

- AIRTIGHT CHECK

- Removal and Installation

- COMPONENTS

- REMOVAL

- INSPECTION AFTER REMOVAL

- Output Rod Length Inspection

- INSTALLATION

- VACUUM LINES

- Component

- Removal and Installation

- Inspection

- VISUAL INSPECTION

- CHECK VALVE INSPECTION

- Airtightness Inspection

- FRONT DISC BRAKE

- On-Board Inspection

- PAD WEAR INSPECTION

- Component

- Removal and Installation of Brake Pad

- REMOVAL

- INSTALLATION

- Removal and Installation of Brake Caliper Assembly

- REMOVAL

- INSTALLATION

- Disassembly and Assembly of Brake Caliper Assembly

- DISASSEMBLY

- INSPECTION AFTER DISASSEMBLY

- Cylinder Body

- Torque Member

- Piston

- Sliding Pin, Sliding Pin Bolt and Sliding Pin Boot

- ASSEMBLY

- DISC ROTOR INSPECTION

- Visual Inspection

- Runout Inspection

- Thickness Inspection

- BRAKE BURNISHING PROCEDURE

- REAR DRUM BRAKE

- Component

- Removal and Installation of Drum Brake Assembly

- REMOVAL

- INSPECTION AFTER REMOVAL

- Lining Thickness Inspection

- Drum Inner Diameter Inspection

- Wheel Cylinder Leakage Inspection

- Other Inspections

- INSTALLATION

- Removal and Installation of Wheel Cylinder

- REMOVAL

- INSTALLATION

- Disassembly and Assembly of Wheel Cylinder

- DISASSEMBLY

- INSPECTION AFTER DISASSEMBLY

- ASSEMBLY

- SERVICE DATA AND SPECIFICATIONS (SDS)

- General Specification

- Brake Pedal

- Brake Booster

- Check Valve

- Front Disc Brake

- Rear Disc Brake

- BRC

- BRAKE CONTROL SYSTEM

- ABS

- SERVICE INFORMATION

- DTC INDEX

- C1101 - C1115

- C1120 - C1191

- U1000

- PRECAUTIONS

- Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER"

- PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

- Precaution for Brake System

- Precaution for Brake Control

- PREPARATION

- Special Service Tool

- SYSTEM DESCRIPTION

- Schematic

- Functions

- ABS

- EBD

- Operation That Is Not "System Error"

- ABS

- Fail-Safe Function

- ABS, EBD SYSTEM

- Hydraulic Circuit Diagram

- CAN COMMUNICATION

- System Description

- TROUBLE DIAGNOSIS

- How to Perform Trouble Diagnosis for Quick and Accurate Repair

- INTRODUCTION

- DIAGNOSIS FLOWCHART

- ASKING COMPLAINTS

- EXAMPLE OF DIAGNOSIS SHEET

- Component Parts Location

- Schematic - ABS -

- Wiring Diagram - ABS -

- Control Unit Input/Output Signal Standad

- REFERENCE VALUE FROM CONSULT-III

- CONSULT-III Functions

- CONSULT-III MAIN FUNCTION

- Self-Diagnosis

- OPERATION PROCEDURE

- ERASE MEMORY

- Display Item List

- Data Monitor

- DISPLAY ITEM LIST

- Active Test

- SOLENOID VALVE

- ABS MOTOR

- For Fast and Accurate Diagnosis

- PRECAUTIONS FOR DIAGNOSIS

- Basic Inspection

- BASIC INSPECTION 1 BRAKE FLUID LEVEL, LEAKS, AND BRAKE PADS

- BASIC INSPECTION 2 POWER SYSTEM TERMINAL LOOSENESS AND BATTERY INSPECTION

- BASIC INSPECTION 3 ABS WARNING LAMP AND BRAKE WARNING LAMP INSPECTION

- ON and OFF Timing for ABS Warning Lamp, Brake Warning Lamp

- Inspection 1 Wheel Sensor System

- Inspection 2 ABS Actuator and Electric Unit (Control Unit)

- Inspection 3 ABS Actuator Relay or ABS Motor Relay Circuit

- Inspection 4 CAN Communication Circuit

- Inspection 5 ABS Actuator and Electric Unit (Control Unit) Power Supply and Ground Circuit

- Inspection 6 Brake Fluid Level Switch Circuit

- Inspection 7 Parking Brake Switch Circuit

- Inspection 8 Warning lamp system

- Symptom 1 Excessive ABS Function Operation Frequency

- Symptom 2 Unexpected Pedal Reaction

- Symptom 3 the Stopping Distance Is Long

- Symptom 4 ABS Function Does Not Operate

- Symptom 5 Pedal Vibration or ABS Operation Sound Occurs

- Symptom 6 ABS Warning Lamp Indication Is Not Normal

- WHEEL SENSOR

- Removal and Installation

- REMOVAL

- INSTALLATION

- SENSOR ROTOR

- Removal and Installation

- FRONT

- REAR

- Removal

- Installation

- ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

- Removal and Installation

- REMOVAL

- INSTALLATION

- CL

- CLUTCH

- SERVICE INFORMATION

- PRECAUTIONS

- Service Notice or Precaution

- PREPARATION

- Special Service Tool

- Commercial Service Tool

- NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

- NVH Troubleshooting Chart

- CLUTCH PEDAL

- On Board Inspection

- HEIGHT INSPECTION

- PLAY INSPECTION

- CLEARANCE CHECK

- Removal and Installation

- COMPONENTS

- REMOVAL

- INSPECTION AFTER REMOVAL

- INSTALLATION

- CLUTCH FLUID

- Air Bleeding Procedure

- CLUTCH MASTER CYLINDER

- Component

- Removal and Installation

- REMOVAL

- INSTALLATION

- Disassembly and Assembly

- DISASSEMBLY

- INSPECTION AFTER DISASSEMBLY

- ASSEMBLY

- OPERATING CYLINDER

- Component

- Removal and Installation

- REMOVAL

- INSTALLATION

- Disassembly and Assembly

- DISASSEMBLY

- INSPECTION AFTER DISASSEMBLY

- ASSEMBLY

- CLUTCH PIPING

- Removal and Installation

- CLUTCH RELEASE MECHANISM

- Removal and Installation

- COMPONENTS

- REMOVAL

- INSPECTION AFTER REMOVAL

- INSTALLATION

- CLUTCH DISC, CLUTCH COVER AND FLYWHEEL

- Removal and Installation

- COMPONENTS

- REMOVAL

- INSPECTION AND ADJUSTMENT AFTER REMOVAL

- Clutch Disc

- Clutch Cover

- Flywheel Runout

- INSTALLATION

- SERVICE DATA AND SPECIFICATIONS (SDS)

- Clutch Control System

- Clutch Master Cylinder

- Clutch Operating Cylinder

- Clutch Disc

- Clutch Cover

- Clutch Pedal

- CO

- ENGINE COOLING SYSTEM

- VQ

- SERVICE INFORMATION

- PRECAUTIONS

- Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER"

- Precaution for Liquid Gasket

- REMOVAL OF LIQUID GASKET SEALING

- LIQUID GASKET APPLICATION PROCEDURE

- PREPARATION

- Special Service Tool

- Commercial Service Tool

- OVERHEATING CAUSE ANALYSIS

- Troubleshooting Chart

- COOLING SYSTEM

- Cooling Circuit

- System Chart

- ENGINE COOLANT

- Inspection

- LEVEL CHECK

- CHECKING RADIATOR SYSTEM FOR LEAKS

- Changing Engine Coolant

- DRAINING ENGINE COOLANT (VIN

- DRAINING ENGINE COOLANT (VIN >VSK***D40*0108061)

- REFILLING ENGINE COOLANT

- FLUSHING COOLING SYSTEM

- RADIATOR

- Component (VIN

- Component (VIN >VSK***D40*0108061)

- Removal and Installation

- REMOVAL

- INSPECTION AFTER REMOVAL

- Checking Reservoir Tank Cap

- Checking Radiator

- INSTALLATION

- INSPECTION AFTER INSTALLATION

- RADIATOR (ALUMINUM TYPE)

- Component

- Disassembly and Assembly

- PREPARATION

- DISASSEMBLY

- ASSEMBLY

- INSPECTION

- COOLING FAN

- Component (Crankshaft Driven Type)

- Removal and Installation (Crankshaft Driven Type)

- REMOVAL

- INSPECTION AFTER REMOVAL

- Fan Coupling

- Fan bracket

- INSTALLATION

- Removal and Installation (Motor Driven Type)

- REMOVAL

- INSTALLATION

- WATER PUMP

- Component

- Removal and Installation

- REMOVAL

- INSPECTION AFTER REMOVAL

- INSTALLATION

- INSPECTION AFTER INSTALLATION

- WATER INLET AND THERMOSTAT ASSEMBLY

- Removal and Installation

- REMOVAL

- INSPECTION AFTER REMOVAL

- INSTALLATION

- INSPECTION AFTER INSTALLATION

- WATER OUTLET AND WATER PIPING

- Component

- Removal and Installation

- REMOVAL

- INSTALLATION

- INSPECTION AFTER INSTALLATION

- SERVICE DATA AND SPECIFICATIONS (SDS)

- Standard and Limit

- ENGINE COOLANT CAPACITY

- THERMOSTAT

- RESERVOIR TANK

- YD

- SERVICE INFORMATION

- PRECAUTIONS

- Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER"

- Precaution for Liquid Gasket

- LIQUID GASKET APPLICATION PROCEDURE

- PREPARATION

- Special Service Tool

- Commercial Service Tool

- OVERHEATING CAUSE ANALYSIS

- Troubleshooting Chart

- COOLING SYSTEM

- Cooling Circuit

- ENGINE COOLANT

- Inspection

- LEVEL CHECK

- CHECKING RADIATOR SYSTEM FOR LEAKS

- Changing Engine Coolant

- DRAINING ENGINE COOLANT (VIN <***D40*0108060)

- DRAINING ENGINE COOLANT (VIN >***D40*0108061)

- REFILLING ENGINE COOLANT

- FLUSHING COOLING SYSTEM

- RADIATOR

- Component (VIN

- Component (VIN >VSK***D40*0108061)

- Removal and Installation

- REMOVAL

- INSPECTION AFTER REMOVAL

- Checking Reservoir Tank Cap

- Checking Radiator

- INSTALLATION

- INSPECTION AFTER INSTALLATION

- RADIATOR (ALUMINUM TYPE)

- Component

- Disassembly and Assembly

- PREPARATION

- DISASSEMBLY

- ASSEMBLY

- INSPECTION

- COOLING FAN

- Component (Crankshaft Driven Type)

- Removal and Installation

- REMOVAL

- INSPECTION AFTER REMOVAL

- Fan Coupling

- INSTALLATION

- Removal and Installation (Motor Driven Type) (Models with A/C)

- REMOVAL

- INSTALLATION

- WATER PUMP

- Component

- Removal and Installation

- REMOVAL

- INSPECTION AFTER REMOVAL

- INSTALLATION

- INSPECTION AFTER INSTALLATION

- THERMOSTAT AND WATER PIPING

- Component

- Removal and Installation

- REMOVAL

- INSPECTION AFTER REMOVAL

- Thermostat

- INSTALLATION

- INSPECTION AFTER INSTALLATION

- SERVICE DATA AND SPECIFICATIONS (SDS)

- Standard and Limit

- ENGINE COOLANT CAPACITY

- THERMOSTAT

- RESERVOIR TANK

- DI

- DRIVER INFORMATION SYSTEM

- SERVICE INFORMATION

- DTC INDEX

- U1000

- B2205

- PRECAUTION

- Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER"

- PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

- Precaution for SRS "AIR BAG" and "SEAT BELT PRE-TENSIONER" Service

- COMBINATION METERS

- System Description

- UNIFIED METER CONTROL UNIT

- POWER SUPPLY AND GROUND CIRCUIT

- SPEEDOMETER

- With ABS

- Without ABS

- TACHOMETER

- WATER TEMPERATURE GAUGE

- FUEL GAUGE

- YD Engine Models

- VQ Engine Models

- ODO/TRIP METER

- With ABS

- Without ABS

- ENGINE OIL MAINTENANCE INFORMATION

- Outline

- Setup Procedure

- METER ILLUMINATION CONTROL

- CLOCK

- AMBIENT AIR TEMPERATURE INDICATION

- Arrangement of Combination Meter

- Component Parts and Harness Connector Location

- Internal Circuit

- Wiring Diagram - METER -

- Terminal and Reference Value for Combination Meter

- Self-Diagnosis Mode of Combination Meter

- FUNCTION

- OPERATION PROCEDURE

- TEST ITEM

- CONSULT-III Function (METER/M&A)

- SELF DIAGNOSTIC RESULT

- DATA MONITOR

- Trouble Diagnosis

- HOW TO PERFORM TROUBLE DIAGNOSIS

- PRELIMINARY CHECK

- Symptom Chart

- Power Supply and Ground Circuit Inspection

- Vehicle Speed Signal Inspection [With ABS]

- Vehicle Speed Signal Inspection [Without ABS]

- Engine Speed Signal Inspection

- Engine Coolant Temperature Signal Inspection

- Fuel Level Sensor Signal Inspection [YD Engine models]

- Fuel Level Sensor Signal Inspection [VQ Engine Models]

- Ambient Sensor Signal Inspection

- Fuel Gauge Fluctuates, Indicates Wrong Value, or Varies

- Fuel Gauge Does Not Move to Full-position

- DTC [U1000] CAN Communication Circuit

- DTC [B2205] Vehicle Speed Circuit

- Electrical Component Inspection

- VEHICLE SPEED SENSOR CHECK

- FUEL LEVEL SENSOR UNIT CHECK [YD ENGINE MODELS]

- Check Fuel Level Sensor Unit

- FUEL LEVEL SENSOR UNIT CHECK [VQ ENGINE MODELS]

- Check Fuel Level Sensor Unit and Fuel Pump

- AMBIENT SENSOR CHECK

- Removal and Installation of Combination Meter

- WARNING LAMPS

- System Description

- OIL PRESSURE WARNING LAMP

- Oil Pressure Warning

- Oil Level Warning [YD Engine Models Only]

- Component Parts and Harness Connector Location

- Schematic

- Wiring Diagram - WARN -

- A/T MODELS

- M/T MODELS

- Oil Pressure Warning Lamp Stays Off (Ignition Switch ON)

- Oil Pressure Warning Lamp Does Not Turn Off (Oil Pressure Is Normal)

- Oil Pressure Warning Lamp Keeps Blinking (Oil Level Is Normal)

- Component Inspection

- OIL PRESSURE SWITCH

- OIL LEVEL SENSOR

- A/T INDICATOR

- System Description

- Wiring Diagram - AT/IND -

- A/T Indicator Does Not Illuminate

- WARNING CHIME

- System Description

- POWER SUPPLY AND GROUND CIRCUIT

- LIGHT WARNING CHIME

- KEY REMINDER WARNING CHIME

- LOW-FUEL WARNING CHIME

- Component Parts and Harness Connector Location

- Wiring Diagram - CHIME -

- Terminal and Reference Value for BCM

- Terminal and Reference Value for Combination Meter

- CONSULT-III Function (BCM)

- DIAGNOSTIC ITEMS DESCRIPTION

- DATA MONITOR

- ACTIVE TEST

- SELF DIAGNOSTIC RESULT

- Trouble Diagnosis

- HOW TO PERFORM TROUBLE DIAGNOSIS

- PRELIMINARY INSPECTION

- SYMPTOM CHART

- Meter Buzzer Circuit Inspection

- Lighting Switch Signal Inspection

- Front Door Switch (Driver Side) Signal Inspection

- Electrical Component Inspection

- FRONT DOOR SWITCH (DRIVER SIDE)

- CAN COMMUNICATION

- System Description

- CAN Communication Unit

- COMPASS

- System Description

- DIRECTION DISPLAY

- Zone Variation Change Procedure

- Correction Functions of the Compass Display

- AUTOMATIC CORRECTION

- MANUAL CORRECTION PROCEDURE

- Wiring Diagram - COMPAS -

- Removal and Installation of Compass

- EC

- ENGINE CONTROL SYSTEM

- APPLICATION NOTICE

- SERVICE INFORMATION

- APPLICATION NOTICE

- How to Check Vehicle Type

- VQ TYPE 1

- SERVICE INFORMATION

- INDEX FOR DTC

- DTC No. Index (U1000 - U1001)

- DTC No. Index (P0011 - P0058)

- DTC No. Index (P0102 - P0123)

- DTC No. Index (P0138 - P0223)

- DTC No. Index (P0300 - P0306)

- DTC No. Index (P0327 - P0605)

- DTC No. Index (P1031 - P1136)

- DTC No. Index (P1146 - P1229)

- DTC No. Index (P1271 - P1289)

- DTC No. Index (P1564 - P1805)

- DTC No. Index (P2122 - P2138)

- PRECAUTIONS

- Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER"

- On Board Diagnosis (OBD) System of Engine

- Precaution

- PREPARATION

- Special Service Tool

- Commercial Service Tool

- ENGINE CONTROL SYSTEM

- Schematic

- Multiport Fuel Injection (MFI) System

- INPUT/OUTPUT SIGNAL CHART

- SYSTEM DESCRIPTION

- VARIOUS FUEL INJECTION INCREASE/DECREASE COMPENSATION

- MIXTURE RATIO FEEDBACK CONTROL (CLOSED LOOP CONTROL)

- Open Loop Control

- MIXTURE RATIO SELF-LEARNING CONTROL

- FUEL INJECTION TIMING

- Sequential Multiport Fuel Injection System

- Simultaneous Multiport Fuel Injection System

- FUEL SHUT-OFF

- Electronic Ignition (EI) System

- INPUT/OUTPUT SIGNAL CHART

- SYSTEM DESCRIPTION

- Fuel Cut Control (at No Load and High Engine Speed)

- INPUT/OUTPUT SIGNAL CHART

- SYSTEM DESCRIPTION

- AIR CONDITIONING CUT CONTROL

- Input/Output Signal Chart

- System Description

- AUTOMATIC SPEED CONTROL DEVICE (ASCD)

- System Description

- INPUT/OUTPUT SIGNAL CHART

- BASIC ASCD SYSTEM

- SET OPERATION

- ACCELERATE OPERATION

- CANCEL OPERATION

- COAST OPERATION

- RESUME OPERATION

- Component Description

- ASCD STEERING SWITCH

- ASCD BRAKE SWITCH

- STOP LAMP SWITCH

- ELECTRIC THROTTLE CONTROL ACTUATOR

- ASCD INDICATOR

- CAN COMMUNICATION

- System Description

- EVAPORATIVE EMISSION SYSTEM

- Description

- SYSTEM DESCRIPTION

- EVAPORATIVE EMISSION LINE DRAWING

- Component Inspection

- EVAP CANISTER

- FUEL TANK VACUUM RELIEF VALVE (BUILT INTO FUEL FULLER CAP)

- EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

- EVAP CANISTER VENT CONTROL VALVE

- POSITIVE CRANKCASE VENTILATION

- Description

- SYSTEM DESCRIPTION

- Component Inspection

- PCV (POSITIVE CRANKCASE VENTILATION) VALVE

- PCV VALVE VENTILATION HOSE

- NATS (NISSAN ANTI-THEFT SYSTEM)

- Description

- ON BOARD DIAGNOSTIC (OBD) SYSTEM

- Introduction

- Two Trip Detection Logic

- Emission-related Diagnostic Information

- EMISSION-RELATED DIAGNOSTIC INFORMATION ITEMS

- DTC AND 1ST TRIP DTC

- How to Read DTC and 1st Trip DTC

- FREEZE FRAME DATA AND 1ST TRIP FREEZE FRAME DATA

- SYSTEM READINESS TEST (SRT) CODE

- SRT Item

- SRT Set Timing

- SRT Service Procedure

- How to Display SRT Code

- How to Set SRT Code

- Driving Pattern

- TEST VALUE AND TEST LIMIT (GST ONLY - NOT APPLICABLE TO CONSULT-III)

- HOW TO ERASE EMISSION-RELATED DIAGNOSTIC INFORMATION

- How to Erase DTC

- Malfunction Indicator Lamp (MIL)

- DESCRIPTION

- ON BOARD DIAGNOSTIC SYSTEM FUNCTION

- HOW TO SWITCH DIAGNOSTIC TEST MODE

- How to Set Diagnostic Test Mode II (Self-diagnostic Results)

- How to Erase Diagnostic Test Mode II (Self-diagnostic Results)

- DIAGNOSTIC TEST MODE I - BULB CHECK

- DIAGNOSTIC TEST MODE I - MALFUNCTION WARNING

- DIAGNOSTIC TEST MODE II - SELF-DIAGNOSTIC RESULTS

- How to Erase Diagnostic Test Mode II (Self-diagnostic Results)

- OBD System Operation Chart

- RELATIONSHIP BETWEEN MIL, 1ST TRIP DTC, DTC, AND DETECTABLE ITEMS

- SUMMARY CHART

- RELATIONSHIP BETWEEN MIL, DTC, 1ST TRIP DTC AND DRIVING PATTERNS FOR “MISFIRE ” , “FUEL INJECTION SYSTEM”

- EXPLANATION FOR DRIVING PATTERNS FOR “MISFIRE ”, “FUEL INJECTION SYSTEM”

- RELATIONSHIP BETWEEN MIL, DTC, 1ST TRIP DTC AND DRIVING PATTERNS EXCEPT FOR “MISFIRE ”, “FUEL INJECTION SYSTEM”

- EXPLANATION FOR DRIVING PATTERNS EXCEPT FOR “MISFIRE ”, “FUEL INJECTION SYSTEM”

- BASIC SERVICE PROCEDURE

- Basic Inspection

- Idle Speed and Ignition Timing Check

- IDLE SPEED

- With CONSULT-III

- With GST

- IGNITION TIMING

- Method A

- Method B

- Accelerator Pedal Released Position Learning

- DESCRIPTION

- OPERATION PROCEDURE

- Throttle Valve Closed Position Learning

- DESCRIPTION

- OPERATION PROCEDURE

- Idle Air Volume Learning

- DESCRIPTION

- PREPARATION

- OPERATION PROCEDURE

- With CONSULT-III

- Without CONSULT-III

- DIAGNOSTIC PROCEDURE

- Fuel Pressure Check

- FUEL PRESSURE RELEASE

- With CONSULT-III

- Without CONSULT-III

- FUEL PRESSURE CHECK

- TROUBLE DIAGNOSIS

- Trouble Diagnosis Introduction

- INTRODUCTION

- WORK FLOW

- Overall Sequence

- Detailed Flow

- DIAGNOSTIC WORKSHEET

- Description

- Worksheet Sample

- DTC Inspection Priority Chart

- Fail-Safe Chart

- Symptom Matrix Chart

- SYSTEM - BASIC ENGINE CONTROL SYSTEM

- SYSTEM - ENGINE MECHANICAL & OTHER

- Engine Control Component Parts Location

- Vacuum Hose Drawing

- Circuit Diagram

- ECM Harness Connector Terminal Layout

- ECM Terminal and Reference Value

- PREPARATION

- ECM INSPECTION TABLE

- CONSULT-III Function (ENGINE)

- FUNCTION

- ENGINE CONTROL COMPONENT PARTS/CONTROL SYSTEMS APPLICATION

- INSPECTION PROCEDURE

- WORK SUPPORT MODE

- Work Item

- SELF-DIAG RESULTS MODE

- Self Diagnostic Item

- Freeze Frame Data and 1st Trip Freeze Frame Data

- DATA MONITOR MODE

- Monitored Item

- DATA MONITOR (SPEC) MODE

- Monitored Item

- ACTIVE TEST MODE

- Test Item

- DTC & SRT CONFIRMATION MODE

- SRT STATUS Mode

- SRT Work Support Mode

- DTC Work Support Mode

- REAL TIME DIAGNOSIS IN DATA MONITOR MODE (RECORDING VEHICLE DATA)

- Description

- Operation

- Generic Scan Tool (GST) Function

- DESCRIPTION

- FUNCTION

- INSPECTION PROCEDURE

- CONSULT-III Reference Value in Data Monitor Mode

- Major Sensor Reference Graph in Data Monitor Mode

- CLSD THL POS, ACCEL SEN 1, THRTL SEN 1

- ENG SPEED, MAS A/F SE-B1, THRTL SEN 1, HO2S2 (B1), INJ PULSE-B1

- TROUBLE DIAGNOSIS - SPECIFICATION VALUE

- Description

- Testing Condition

- Inspection Procedure

- Diagnosis Procedure

- OVERALL SEQUENCE

- DETAILED PROCEDURE

- TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT

- Description

- Diagnosis Procedure

- POWER SUPPLY AND GROUND CIRCUIT

- Wiring Diagram

- Diagnosis Procedure

- Ground Inspection

- DTC U1000, U1001 CAN COMMUNICATION LINE

- Description

- On Board Diagnosis Logic

- DTC Confirmation Procedure

- Wiring Diagram

- Diagnosis Procedure

- DTC P0011, P0021 IVT CONTROL

- Description

- SYSTEM DESCRIPTION

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- FAIL-SAFE MODE

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Diagnosis Procedure

- Component Inspection

- INTAKE VALVE TIMING CONTROL SOLENOID VALVE

- Removal and Installation

- INTAKE VALVE TIMING CONTROL SOLENOID VALVE

- DTC P0037, P0038, P0057, P0058 HO2S2 HEATER

- Description

- SYSTEM DESCRIPTION

- OPERATION

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Wiring Diagram

- BANK 1

- BANK 2

- Diagnosis Procedure

- Component Inspection

- HEATED OXYGEN SENSOR 2 HEATER

- Removal and Installation

- HEATED OXYGEN SENSOR 2

- DTC P0102, P0103 MAF SENSOR

- Component Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- FAIL-SAFE MODE

- DTC Confirmation Procedure

- PROCEDURE FOR DTC P0102

- With CONSULT-III

- With GST

- PROCEDURE FOR DTC P0103

- With CONSULT-III

- With GST

- Wiring Diagram

- Diagnosis Procedure

- Component Inspection

- MASS AIR FLOW SENSOR

- With CONSULT-III

- Without CONSULT-III

- Removal and Installation

- MASS AIR FLOW SENSOR

- DTC P0112, P0113 IAT SENSOR

- Component Description

- On Board Diagnosis Logic

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Wiring Diagram

- Diagnosis Procedure

- Component Inspection

- INTAKE AIR TEMPERATURE SENSOR

- Removal and Installation

- MASS AIR FLOW SENSOR

- DTC P0117, P0118 ECT SENSOR

- Component Description

- On Board Diagnosis Logic

- FAIL-SAFE MODE

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Wiring Diagram

- Diagnosis Procedure

- Component Inspection

- ENGINE COOLANT TEMPERATURE SENSOR

- Removal and Installation

- ENGINE COOLANT TEMPERATURE SENSOR

- DTC P0122, P0123 TP SENSOR

- Component Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- FAIL-SAFE MODE

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Wiring Diagram

- Diagnosis Procedure

- Component Inspection

- THROTTLE POSITION SENSOR

- Removal and Installation

- ELECTRIC THROTTLE CONTROL ACTUATOR

- DTC P0138, P0158 HO2S2

- Component Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Wiring Diagram

- BANK 1

- BANK 2

- Diagnosis Procedure

- Component Inspection

- HEATED OXYGEN SENSOR 2

- With CONSULT-III

- Without CONSULT-III

- Removal and Installation

- HEATED OXYGEN SENSOR 2

- DTC P0139, P0159 HO2S2

- Component Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- DTC Confirmation Procedure

- WITH CONSULT-III

- Procedure for COND1

- Procedure for COND2

- Procedure for COND3

- Overall Function Check

- WITH GST

- Wiring Diagram

- BANK 1

- BANK 2

- Diagnosis Procedure

- Component Inspection

- HEATED OXYGEN SENSOR 2

- With CONSULT-III

- Without CONSULT-III

- Removal and Installation

- HEATED OXYGEN SENSOR 2

- DTC P0171, P0174 FUEL INJECTION SYSTEM FUNCTION

- On Board Diagnosis Logic

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Wiring Diagram

- BANK 1

- BANK 2

- Diagnosis Procedure

- DTC P0172, P0175 FUEL INJECTION SYSTEM FUNCTION

- On Board Diagnosis Logic

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Wiring Diagram

- BANK 1

- BANK 2

- Diagnosis Procedure

- DTC P0222, P0223 TP SENSOR

- Component Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- FAIL-SAFE MODE

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Wiring Diagram

- Diagnosis Procedure

- Component Inspection

- THROTTLE POSITION SENSOR

- Removal and Installation

- ELECTRIC THROTTLE CONTROL ACTUATOR

- DTC P0300, P0301, P0302, P0303, P0304, P0305, P0306 MULTIPLE CYLINDER MISFIRE, NO. 1 - 6 CYLINDER MISFIRE

- On Board Diagnosis Logic

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Diagnosis Procedure

- DTC P0327, P0328, P0332, P0333 KS

- Component Description

- On Board Diagnosis Logic

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Wiring Diagram

- Diagnosis Procedure

- Component Inspection

- KNOCK SENSOR

- Removal and Installation

- KNOCK SENSOR

- DTC P0335 CKP SENSOR (POS)

- Component Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Wiring Diagram

- Diagnosis Procedure

- Component Inspection

- CRANKSHAFT POSITION SENSOR (POS)

- Removal and Installation

- CRANKSHAFT POSITION SENSOR (POS)

- DTC P0340, P0345 CMP SENSOR (PHASE)

- Component Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Wiring Diagram

- BANK 1

- BANK 2

- Diagnosis Procedure

- Component Inspection

- CAMSHAFT POSITION SENSOR (PHASE)

- Removal and Installation

- CAMSHAFT POSITION SENSOR (PHASE)

- DTC P0420, P0430 THREE WAY CATALYST FUNCTION

- On Board Diagnosis Logic

- DTC Confirmation Procedure

- WITH CONSULT-III

- Overall Function Check

- WITH GST

- Diagnosis Procedure

- DTC P0444, P0445 EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

- Description

- SYSTEM DESCRIPTION

- COMPONENT DESCRIPTION

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Wiring Diagram

- Diagnosis Procedure

- Component Inspection

- EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

- With CONSULT-III

- Without CONSULT-III

- Removal and Installation

- EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

- DTC P0500 VSS

- Description

- On Board Diagnosis Logic

- DTC Confirmation Procedure

- WITH CONSULT-III

- Overall Function Check

- WITH GST

- Diagnosis Procedure

- DTC P0550 PSP SENSOR

- Component Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Wiring Diagram

- Diagnosis Procedure

- Component Inspection

- POWER STEERING PRESSURE SENSOR

- Removal and Installation

- POWER STEERING PRESSURE SENSOR

- DTC P0605 ECM

- Component Description

- On Board Diagnosis Logic

- FAIL-SAFE MODE

- DTC Confirmation Procedure

- PROCEDURE FOR MALFUNCTION A

- With CONSULT-III

- With GST

- PROCEDURE FOR MALFUNCTION B

- With CONSULT-III

- With GST

- PROCEDURE FOR MALFUNCTION C

- With CONSULT-III

- With GST

- Diagnosis Procedure

- DTC P1031, P1032, P1051, P1052 A/F SENSOR 1 HEATER

- Description

- SYSTEM DESCRIPTION

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Wiring Diagram

- BANK 1

- BANK 2

- Diagnosis Procedure

- Component Inspection

- AIR FUEL RATIO (A/F) SENSOR 1 HEATER

- Removal and Installation

- AIR FUEL RATIO (A/F) SENSOR 1

- DTC P1065 ECM POWER SUPPLY

- Component Description

- On Board Diagnosis Logic

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Wiring Diagram

- Diagnosis Procedure

- DTC P1111, P1136 IVT CONTROL SOLENOID VALVE

- Component Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Wiring Diagram

- BANK 1

- BANK 2

- Diagnosis Procedure

- Component Inspection

- INTAKE VALVE TIMING CONTROL SOLENOID VALVE

- Removal and Installation

- INTAKE VALVE TIMING CONTROL SOLENOID VALVE

- DTC P1121 ELECTRIC THROTTLE CONTROL ACTUATOR

- Component Description

- On Board Diagnosis Logic

- FAIL-SAFE MODE

- DTC Confirmation Procedure

- PROCEDURE FOR MALFUNCTION A AND B

- With CONSULT-III

- With GST

- PROCEDURE FOR MALFUNCTION C

- With CONSULT-III

- With GST

- Diagnosis Procedure

- DTC P1122 ELECTRIC THROTTLE CONTROL FUNCTION

- Description

- On Board Diagnosis Logic

- FAIL-SAFE MODE

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Wiring Diagram

- Diagnosis Procedure

- Component Inspection

- THROTTLE CONTROL MOTOR

- Removal and Installation

- ELECTRIC THROTTLE CONTROL ACTUATOR

- DTC P1124, P1126 THROTTLE CONTROL MOTOR RELAY

- Component Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- FAIL-SAFE MODE

- DTC Confirmation Procedure

- PROCEDURE FOR DTC P1124

- With CONSULT-III

- With GST

- PROCEDURE FOR DTC P1126

- With CONSULT-III

- With GST

- Wiring Diagram

- Diagnosis Procedure

- DTC P1128 THROTTLE CONTROL MOTOR

- Component Description

- On Board Diagnosis Logic

- FAIL-SAFE MODE

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Wiring Diagram

- Diagnosis Procedure

- Component Inspection

- THROTTLE CONTROL MOTOR

- Removal and Installation

- ELECTRIC THROTTLE CONTROL ACTUATOR

- DTC P1146, P1166 HO2S2

- Component Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- DTC Confirmation Procedure

- WITH CONSULT-III

- Procedure for COND1

- Procedure for COND2

- Procedure for COND3

- Overall Function Check

- WITH GST

- Wiring Diagram

- BANK 1

- BANK 2

- Diagnosis Procedure

- Component Inspection

- HEATED OXYGEN SENSOR 2

- With CONSULT-III

- Without CONSULT-III

- Removal and Installation

- HEATED OXYGEN SENSOR 2

- DTC P1147, P1167 HO2S2

- Component Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- DTC Confirmation Procedure

- WITH CONSULT-III

- Procedure for COND1

- Procedure for COND2

- Procedure for COND3

- Overall Function Check

- WITH GST

- Wiring Diagram

- BANK 1

- BANK 2

- Diagnosis Procedure

- Component Inspection

- HEATED OXYGEN SENSOR 2

- With CONSULT-III

- Without CONSULT-III

- Removal and Installation

- HEATED OXYGEN SENSOR 2

- DTC P1217 ENGINE OVER TEMPERATURE

- Description

- SYSTEM DESCRIPTION

- Cooling Fan Control

- Cooling Fan Operation

- Cooling Fan Relay Operation

- COMPONENT DESCRIPTION

- Cooling Fan Motor

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- Overall Function Check

- WITH CONSULT-III

- WITH GST

- Wiring Diagram

- Diagnosis Procedure

- PROCEDURE A

- Main 12 Causes of Overheating

- Component Inspection

- COOLING FAN MOTOR

- DTC P1225 TP SENSOR

- Component Description

- On Board Diagnosis Logic

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Diagnosis Procedure

- Removal and Installation

- ELECTRIC THROTTLE CONTROL ACTUATOR

- DTC P1226 TP SENSOR

- Component Description

- On Board Diagnosis Logic

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Diagnosis Procedure

- Removal and Installation

- ELECTRIC THROTTLE CONTROL ACTUATOR

- DTC P1229 SENSOR POWER SUPPLY

- On Board Diagnosis Logic

- FAIL-SAFE MODE

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Wiring Diagram

- Diagnosis Procedure

- DTC P1271, P1281 A/F SENSOR 1

- Component Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Wiring Diagram

- BANK 1

- BANK 2

- Diagnosis Procedure

- Removal and Installation

- AIR FUEL RATIO (A/F) SENSOR 1

- DTC P1272, P1282 A/F SENSOR 1

- Component Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Wiring Diagram

- BANK 1

- BANK 2

- Diagnosis Procedure

- Removal and Installation

- AIR FUEL RATIO (A/F) SENSOR 1

- DTC P1273, P1283 A/F SENSOR 1

- Component Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Wiring Diagram

- BANK 1

- BANK 2

- Diagnosis Procedure

- Removal and Installation

- AIR FUEL RATIO (A/F) SENSOR 1

- DTC P1274, P1284 A/F SENSOR 1

- Component Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Wiring Diagram

- BANK 1

- BANK 2

- Diagnosis Procedure

- Removal and Installation

- AIR FUEL RATIO (A/F) SENSOR 1

- DTC P1276, P1286 A/F SENSOR 1

- Component Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- DTC Confirmation Procedure

- WITH CONSULT-III

- Overall Function Check

- WITH GST

- Wiring Diagram

- BANK 1

- BANK 2

- Diagnosis Procedure

- Removal and Installation

- AIR FUEL RATIO (A/F) SENSOR 1

- DTC P1278, P1288 A/F SENSOR 1

- Component Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Wiring Diagram

- BANK 1

- BANK 2

- Diagnosis Procedure

- Removal and Installation

- AIR FUEL RATIO (A/F) SENSOR 1

- DTC P1279, P1289 A/F SENSOR 1

- Component Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Wiring Diagram

- BANK 1

- BANK 2

- Diagnosis Procedure

- Removal and Installation

- AIR FUEL RATIO (A/F) SENSOR 1

- DTC P1564 ASCD STEERING SWITCH

- Component Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Wiring Diagram

- Diagnosis Procedure

- Component Inspection

- ASCD STEERING SWITCH

- DTC P1572 ASCD BRAKE SWITCH

- Component Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Wiring Diagram

- Diagnosis Procedure

- A/T MODELS

- M/T MODELS

- Component Inspection

- ASCD BRAKE SWITCH

- ASCD CLUTCH SWITCH

- STOP LAMP SWITCH

- DTC P1574 ASCD VEHICLE SPEED SENSOR

- Component Description

- On Board Diagnosis Logic

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Diagnosis Procedure

- DTC P1706 PNP SWITCH

- Component Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- DTC Confirmation Procedure

- WITH CONSULT-III

- Overall Function Check

- WITH GST

- Wiring Diagram

- Diagnosis Procedure

- A/T MODELS

- M/T MODELS

- DTC P1715 INPUT SPEED SENSOR (TURBINE REVOLUTION SENSOR)

- Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- Diagnosis Procedure

- DTC P1805 BRAKE SWITCH

- Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- FAIL-SAFE MODE

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Wiring Diagram

- Diagnosis Procedure

- Component Inspection

- STOP LAMP SWITCH

- DTC P2122, P2123 APP SENSOR

- Component Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- FAIL-SAFE MODE

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Wiring Diagram

- Diagnosis Procedure

- Component Inspection

- ACCELERATOR PEDAL POSITION SENSOR

- Removal and Installation

- ACCELERATOR PEDAL

- DTC P2127, P2128 APP SENSOR

- Component Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- FAIL-SAFE MODE

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Wiring Diagram

- Diagnosis Procedure

- Component Inspection

- ACCELERATOR PEDAL POSITION SENSOR

- Removal and Installation

- ACCELERATOR PEDAL

- DTC P2135 TP SENSOR

- Component Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- FAIL-SAFE MODE

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Wiring Diagram

- Diagnosis Procedure

- Component Inspection

- THROTTLE POSITION SENSOR

- Removal and Installation

- ELECTRIC THROTTLE CONTROL ACTUATOR

- DTC P2138 APP SENSOR

- Component Description

- CONSULT-III Reference Value in Data Monitor Mode

- On Board Diagnosis Logic

- FAIL-SAFE MODE

- DTC Confirmation Procedure

- WITH CONSULT-III

- WITH GST

- Wiring Diagram

- Diagnosis Procedure

- Component Inspection

- ACCELERATOR PEDAL POSITION SENSOR

- Removal and Installation

- ACCELERATOR PEDAL

- ASCD BRAKE SWITCH

- Component Description

- CONSULT-III Reference Value in Data Monitor Mode

- Wiring Diagram

- Diagnosis Procedure

- A/T MODELS

- M/T MODELS

- Component Inspection

- ASCD BRAKE SWITCH

- ASCD CLUTCH SWITCH

- STOP LAMP SWITCH

- ASCD INDICATOR

- Component Description

- CONSULT-III Reference Value in Data Monitor Mode

- Wiring Diagram

- Diagnosis Procedure

- ELECTRICAL LOAD SIGNAL

- Description

- CONSULT-III Reference Value in Data Monitor Mode

- Diagnosis Procedure

- EVAP CANISTER VENT CONTROL VALVE

- Component Description

- Wiring Diagram

- Diagnosis Procedure

- Component Inspection

- EVAP CANISTER VENT CONTROL VALVE

- FUEL INJECTOR

- Component Description

- CONSULT-III Reference Value in Data Monitor Mode

- Wiring Diagram

- Diagnosis Procedure

- Component Inspection

- FUEL INJECTOR

- Removal and Installation

- FUEL INJECTOR

- FUEL PUMP

- Description

- SYSTEM DESCRIPTION

- COMPONENT DESCRIPTION

- CONSULT-III Reference Value in Data Monitor Mode

- Wiring Diagram

- Diagnosis Procedure

- Component Inspection

- FUEL PUMP

- Removal and Installation

- FUEL PUMP

- IGNITION SIGNAL

- Component Description

- IGNITION COIL & POWER TRANSISTOR

- Wiring Diagram

- Diagnosis Procedure

- Component Inspection

- IGNITION COIL WITH POWER TRANSISTOR

- CONDENSER-1

- Removal and Installation

- IGNITION COIL WITH POWER TRANSISTOR

- REFRIGERANT PRESSURE SENSOR

- Component Description

- Wiring Diagram

- Diagnosis Procedure

- Removal and Installation

- REFRIGERANT PRESSURE SENSOR

- VIAS

- Description

- SYSTEM DESCRIPTION

- COMPONENT DESCRIPTION

- Power Valve

- VIAS Control Solenoid Valve

- CONSULT-III Reference Value in Data Monitor Mode

- Wiring Diagram

- Diagnosis Procedure

- Component Inspection

- VIAS CONTROL SOLENOID VALVE

- With CONSULT-III

- Without CONSULT-III

- VACUUM TANK

- Removal and Installation

- VIAS CONTROL SOLENOID VALVE

- MIL AND DATA LINK CONNECTOR

- Wiring Diagram

- SERVICE DATA AND SPECIFICATIONS (SDS)

- Fuel Pressure

- Idle Speed and Ignition Timing

- Calculated Load Value

- Mass Air Flow Sensor

- Intake Air Temperature Sensor

- Engine Coolant Temperature Sensor

- Air Fuel Ratio (A/F) Sensor 1 Heater

- Heated Oxygen sensor 2 Heater

- Crankshaft Position Sensor (POS)

- Camshaft Position Sensor (PHASE)

- Throttle Control Motor

- Fuel Injector

- Fuel Pump

- VQ TYPE 2

- SERVICE INFORMATION

- INDEX FOR DTC

- DTC No. Index (U1000 - U1001)

- DTC No. Index (P0011 - P0123)

- DTC No. Index (P0222 - P0605)

- DTC No. Index (P1031 - P1136)

- DTC No. Index (P1217 - P1286)

- DTC No. Index (P1564 - P1805)

- DTC No. Index (P2122 - P2138)

- PRECAUTIONS

- Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER"

- On Board Diagnosis (OBD) System of Engine

- Precaution

- PREPARATION

- Special Service Tool

- Commercial Service Tool

- ENGINE CONTROL SYSTEM

- Schematic

- Multiport Fuel Injection (MFI) System

- INPUT/OUTPUT SIGNAL CHART

- SYSTEM DESCRIPTION

- VARIOUS FUEL INJECTION INCREASE/DECREASE COMPENSATION

- MIXTURE RATIO FEEDBACK CONTROL (CLOSED LOOP CONTROL)

- Open Loop Control

- MIXTURE RATIO SELF-LEARNING CONTROL

- FUEL INJECTION TIMING

- Sequential Multiport Fuel Injection System

- Simultaneous Multiport Fuel Injection System

- FUEL SHUT-OFF

- Electronic Ignition (EI) System

- INPUT/OUTPUT SIGNAL CHART

- SYSTEM DESCRIPTION

- Fuel Cut Control (at No Load and High Engine Speed)

- INPUT/OUTPUT SIGNAL CHART

- SYSTEM DESCRIPTION

- AIR CONDITIONING CUT CONTROL

- Input/Output Signal Chart

- System Description

- AUTOMATIC SPEED CONTROL DEVICE (ASCD)

- System Description

- INPUT/OUTPUT SIGNAL CHART

- BASIC ASCD SYSTEM

- SET OPERATION

- ACCELERATE OPERATION

- CANCEL OPERATION

- COAST OPERATION

- RESUME OPERATION

- Component Description

- ASCD STEERING SWITCH

- ASCD BRAKE SWITCH

- STOP LAMP SWITCH

- ELECTRIC THROTTLE CONTROL ACTUATOR

- ASCD INDICATOR

- CAN COMMUNICATION

- System Description

- EVAPORATIVE EMISSION SYSTEM

- Description