Technical Highlights

Manufacturer: CNH Industrial (Case & New Holland)

Engine Family: FPT NEF Tier 4a Diesel Engines

Document Type: Factory Emission System Presentation

Date: September 2013

Slides: 46

System Type: Selective Catalytic Reduction (SCR) using Diesel Exhaust Fluid (DEF / AdBlue)

Emission Compliance: Tier 4a (Interim) and Tier 4b (Final) for off-road diesel engines

Coverage

Introduction to Tier 4 Regulations

EPA emission standards and phasing (Tier 1–4b)

90% reduction in PM and NOx required for Tier 4b

Comparison of CO, HC, NOx, and PM limits across engine power ranges

Pollutant Formation and Control

Chemistry of NOx and PM generation during diesel combustion

Relationship between temperature and NOx emissions

Acid rain and health effects from PM inhalation

Emission Solutions for Tier 4

Comparison: SCR vs CEGR/DPF (Exhaust Gas Recirculation with Diesel Particulate Filter)

Advantages of SCR on 850M–2050M dozers (fuel efficiency, less maintenance)

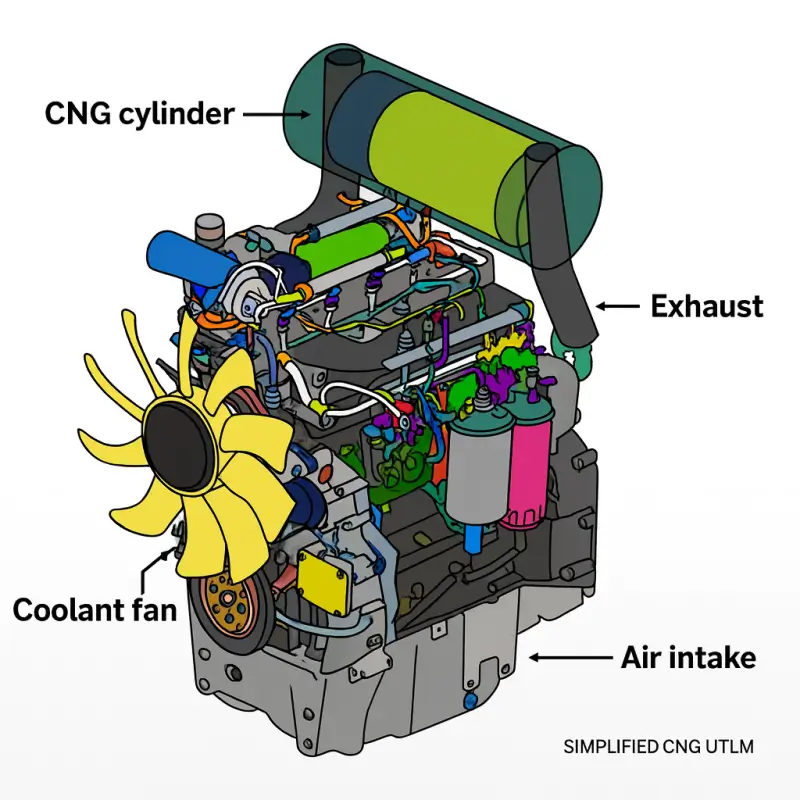

Selective Catalytic Reduction (SCR) Overview

5% fuel savings through high-efficiency combustion

Conversion of NOx to nitrogen (N₂) and water (H₂O) by DEF injection

Core components: DEF tank, supply module, injector, mixing baffle, and catalyst

Component Layout and Hydraulic Scheme

Diagram showing DEF flow circuit between DCU (Dosing Control Unit), Supply Module, and Injector

Pressure range: 5 bar at dosing module (Bosch SM)

Sensors: NOx, temperature (upstream/downstream), DEF level, and humidity

DEF (AdBlue) System and WEMA Tank Module

32.5% urea / 67.5% distilled water composition

Freezing point −11°C; includes coolant-heated WEMA probe

Magnetic fill neck prevents misfuelling and ensures expansion space

DEF Injector and Mixer Assembly

Bosch dosing valve (200 g/h to 9 kg/h)

Active cooling and 54° spray angle

Mixer ensures proper DEF vaporization before catalyst

Filtration and Maintenance Intervals

Inline pre-filter (100 µm Voss) – clean/replace every 600–1200 hrs

Main filter – replace every 1200 hrs

Injector filter – no maintenance required

System Logic and DNOx Function Sequence

Pressure build-up → Reverting valve check → Normal dosing → Afterrun purge

Afterrun (90 seconds): reverses flow to clear DEF lines

Electronics and Diagnostics

ECU & DCU control with 5 sensors and 2 actuators

EST (Electronic Service Tool) and EASY software integration

Urea Dosing System Test (UDST) for performance validation

Faults, Inducements & Tamper Protection

DEF low level, poor quality, SCR failure triggers performance limits

Anti-tamper algorithm prevents software downgrades

Severe inducement = 50% torque reduction + RPM limitation

Delivery

The download link will be sent to your email instantly after payment.

Abrites AVDI J2534

Abrites AVDI J2534 Actia Multi-Diag

Actia Multi-Diag Autoland iSCAN

Autoland iSCAN Bobcat Diagnostic Kit

Bobcat Diagnostic Kit BMW ENET

BMW ENET Bosch Mastertech II J2534

Bosch Mastertech II J2534 Bosch MTS 6531

Bosch MTS 6531 CAN CLIP RLT2002

CAN CLIP RLT2002 CarDAQ-Plus 3

CarDAQ-Plus 3 Cummins INLINE Datalink

Cummins INLINE Datalink Dearborn Protocol Adapter (DPA) 5

Dearborn Protocol Adapter (DPA) 5 Delphi/Autocom DS150E

Delphi/Autocom DS150E DrewLinQ

DrewLinQ Volvo VIDA DiCE

Volvo VIDA DiCE Derelek USB DIAG 3

Derelek USB DIAG 3 Electronic Data Link (EDL) 2

Electronic Data Link (EDL) 2 Electronic Data Link (EDL) 3

Electronic Data Link (EDL) 3 GM MDI 1

GM MDI 1 GM MDI 2

GM MDI 2 HEX-V2 VCDS VAG-COM

HEX-V2 VCDS VAG-COM Isuzu IDSS IDS MX1

Isuzu IDSS IDS MX1 Isuzu IDSS IDS MX2

Isuzu IDSS IDS MX2 Iveco Eltrac E.A.SY. ECI

Iveco Eltrac E.A.SY. ECI MaxiFlash Elite J2534

MaxiFlash Elite J2534 MB Star C6

MB Star C6 Mongoose J2534

Mongoose J2534 Nexiq USB-Link 1

Nexiq USB-Link 1 Nexiq USB-Link 2

Nexiq USB-Link 2 Nexiq USB-Link 3

Nexiq USB-Link 3 Noregon DLA+ 2.0

Noregon DLA+ 2.0 Porsche PIWIS TESTER 3 (PT3G)

Porsche PIWIS TESTER 3 (PT3G) PSA LEXIA 3

PSA LEXIA 3 SAE J2434

SAE J2434 Scania VCI 3

Scania VCI 3 Scanmatik 2 PRO

Scanmatik 2 PRO SD Connect Multiplexer

SD Connect Multiplexer Tactrix OpenPort 2.0

Tactrix OpenPort 2.0 Toyota TIS Mini VCI

Toyota TIS Mini VCI VAG ODIS VAS5054 Clone

VAG ODIS VAS5054 Clone VAG ODIS VAS6154 Clone

VAG ODIS VAS6154 Clone Volvo VOCOM 1

Volvo VOCOM 1 Volvo VOCOM 2

Volvo VOCOM 2 Xentry VCI

Xentry VCI Yanmar Diagnostic Interface Box (IFBOX)

Yanmar Diagnostic Interface Box (IFBOX)

Reviews

Clear filtersThere are no reviews yet.