This manual details the use and diagnostic functions of the Electronic Service Tool (EST) for Tier IV SCR (Selective Catalytic Reduction) engines. It provides comprehensive operational instructions for technicians working on DCU15 (Denoxitronic Control Unit) and ECM (Engine Control Module) systems within CNH equipment.

The guide also includes urea system testing, controller configuration, derate reset, and troubleshooting logic for FPT NEF and Cursor engines equipped with AdBlue/DEF injection systems.

It supports the following machine families:

CASE and New Holland Construction models with Tier IV SCR systems

Agricultural and industrial equipment using FPT DCU15 controllers

Coverage

Controller Status

Displaying connected controllers (DCU15, ECM)

Hardware/software version retrieval

Communication verification and version file saving

Monitor

CAN diagnostic parameter selection

Adding, saving, and viewing real-time SCR parameters

Example Tier IV SCR monitoring list

Programming

DCU15 setup and dataset selection

Download approval and password authorization

Program upload process and verification steps

Additional Tools

Easy Engine Diagnostic Tool (Tier IV DCU15)

Warnings on EASY instability

Functionality identical to NEF/CURSOR diagnostic tools

Configuration

Model-specific controller calibration

Engine Derate Status view

Engine Restart Counter Reset procedure

Engine Derate Status

Real-time NOx monitoring and derate logic

Typical NOx sensor range (500 ppm static → 250 ppm operating)

eVGT, turbo speed, and control mode indicators

Engine Restart Counter Reset

Emergency restart logic (three resets allowed)

Torque and RPM limit reinstatement procedure

Controller Tests

Overview of SCR diagnostic tests:

Urea Dosing System Test (UDST)

Urea System Emptying Routine

Urea Flushing Routine

UDST (Urea Dosing System Test)

Static test (engine off) with 11 validation points

Pump speed, pressure, and injection performance graphs

Acceptable ranges:

Pump speed: 1800–3600 rpm

Pump pressure: 4900–6200 mbar

Throttle pressure: 1500–4300 mbar

Injection pressure drop: >100 mbar

Vacuum test: –50 to –300 mbar

Urea System Emptying Routine

Simulation of post-shutdown DEF purge

Leak detection and pressure decay verification

Urea System Flushing Routine

Line cleaning process without injection

Used after SCR disassembly or service

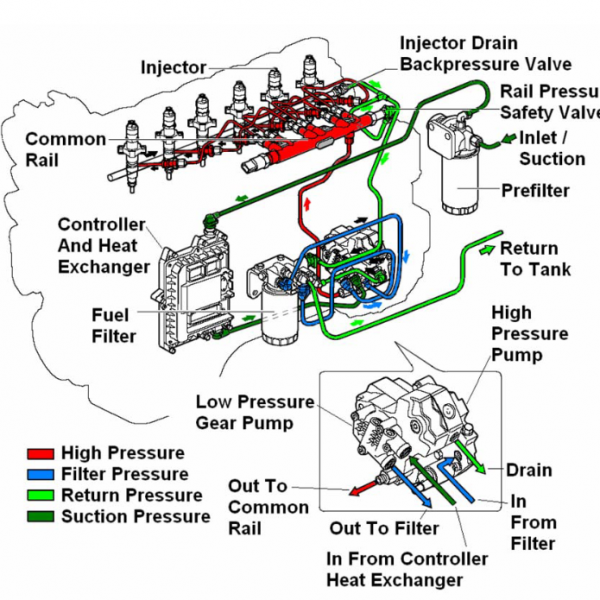

SCR System Troubleshooting

Air in urea system

Leakage and low injection

High-pressure part failures

Pressure line clogging

Pump malfunction

Reverting valve defect

Obstructed throttle and reversed lines

Delivery

The download link will be sent to your email instantly after payment.

Abrites AVDI J2534

Abrites AVDI J2534 Actia Multi-Diag

Actia Multi-Diag Autoland iSCAN

Autoland iSCAN Bobcat Diagnostic Kit

Bobcat Diagnostic Kit BMW ENET

BMW ENET Bosch Mastertech II J2534

Bosch Mastertech II J2534 Bosch MTS 6531

Bosch MTS 6531 CAN CLIP RLT2002

CAN CLIP RLT2002 CarDAQ-Plus 3

CarDAQ-Plus 3 Cummins INLINE Datalink

Cummins INLINE Datalink Dearborn Protocol Adapter (DPA) 5

Dearborn Protocol Adapter (DPA) 5 Delphi/Autocom DS150E

Delphi/Autocom DS150E DrewLinQ

DrewLinQ Volvo VIDA DiCE

Volvo VIDA DiCE Derelek USB DIAG 3

Derelek USB DIAG 3 Electronic Data Link (EDL) 2

Electronic Data Link (EDL) 2 Electronic Data Link (EDL) 3

Electronic Data Link (EDL) 3 GM MDI 1

GM MDI 1 GM MDI 2

GM MDI 2 HEX-V2 VCDS VAG-COM

HEX-V2 VCDS VAG-COM Isuzu IDSS IDS MX1

Isuzu IDSS IDS MX1 Isuzu IDSS IDS MX2

Isuzu IDSS IDS MX2 Iveco Eltrac E.A.SY. ECI

Iveco Eltrac E.A.SY. ECI MaxiFlash Elite J2534

MaxiFlash Elite J2534 MB Star C6

MB Star C6 Mongoose J2534

Mongoose J2534 Nexiq USB-Link 1

Nexiq USB-Link 1 Nexiq USB-Link 2

Nexiq USB-Link 2 Nexiq USB-Link 3

Nexiq USB-Link 3 Noregon DLA+ 2.0

Noregon DLA+ 2.0 Porsche PIWIS TESTER 3 (PT3G)

Porsche PIWIS TESTER 3 (PT3G) PSA LEXIA 3

PSA LEXIA 3 SAE J2434

SAE J2434 Scania VCI 3

Scania VCI 3 Scanmatik 2 PRO

Scanmatik 2 PRO SD Connect Multiplexer

SD Connect Multiplexer Tactrix OpenPort 2.0

Tactrix OpenPort 2.0 Toyota TIS Mini VCI

Toyota TIS Mini VCI VAG ODIS VAS5054 Clone

VAG ODIS VAS5054 Clone VAG ODIS VAS6154 Clone

VAG ODIS VAS6154 Clone Volvo VOCOM 1

Volvo VOCOM 1 Volvo VOCOM 2

Volvo VOCOM 2 Xentry VCI

Xentry VCI Yanmar Diagnostic Interface Box (IFBOX)

Yanmar Diagnostic Interface Box (IFBOX)

Reviews

Clear filtersThere are no reviews yet.