The Kubota L2501 Tractor Workshop Manual is the official factory repair guide for the L2501 model, covering every aspect of maintenance, troubleshooting, and component servicing.

This manual provides detailed procedures for engine, hydraulics, transmission, electrical system, steering, and brakes, along with torque values, diagnostic charts, and special tool references.

It is designed for professional mechanics, service technicians, and owners of Kubota L2501 tractors. Each section includes clear diagrams, safety guidelines, and step-by-step servicing instructions for reliable performance and compliance with Kubota factory standards.

Manual Coverage

Information

Safety Instructions

Safety Decals

Specifications

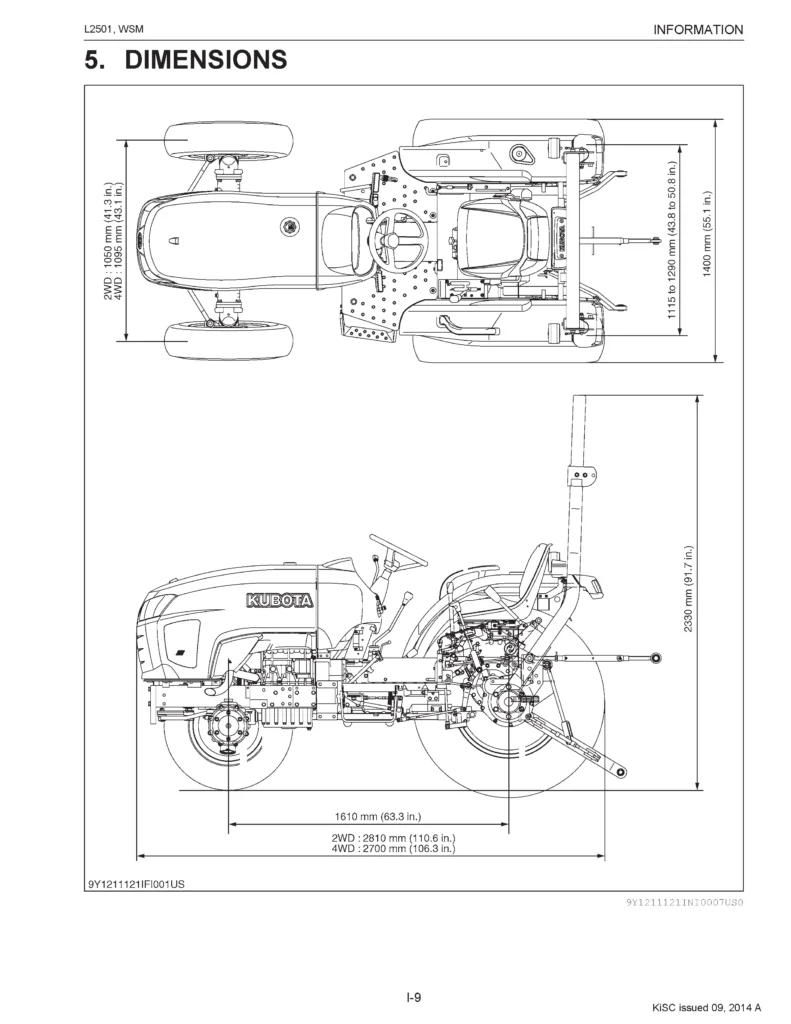

Dimensions & Traveling Speeds

General

Tractor and Engine Identification

Maintenance Intervals and Checklists

Electrical System Precautions

Lubricants, Fuel & Coolant Specifications

Tightening Torques and Special Tools

Tire Pressure, Adjustment & Implement Limitations

Mechanism

Engine System Overview (Refer to Engine Manual 9Y021-01870 / 18200)

Transmission, Clutch, and PTO Layout

Hydraulic Control System Structure

Steering and Brake System Functions

Chassis, Frame, and Suspension Structure

Servicing

Troubleshooting Guide

Servicing Specifications & Tightening Torques

Disassembly and Reassembly Procedures

Component Inspections & Adjustment Procedures

Maintenance Schedules (Daily, 50h–3000h)

- INFORMATION

- SAFETY FIRST

- SAFETY DECALS

- SPECIFICATIONS

- TRAVELING SPEEDS

- DIMENSIONS

- GENERAL

- TRACTOR IDENTIFICATION

- [1] MODEL NAME AND SERIAL NUMBERS

- [2] E4B ENGINE

- [3] CYLINDER NUMBER

- GENERAL PRECAUTIONS

- HANDLING PRECAUTIONS FOR ELECTRICAL PARTS AND WIRING

- [1] WIRING

- [2] BATTERY

- [3] FUSE

- [4] CONNECTOR

- [5] CIRCUIT TESTER

- [6] COLOR OF WIRING

- LUBRICANTS, FUEL AND COOLANT

- TIGHTENING TORQUES

- [1] GENERAL USE SCREWS, BOLTS AND NUTS

- [2] STUD BOLTS

- [3] METRIC SCREWS, BOLTS AND NUTS

- [4] AMERICAN STANDARD SCREWS, BOLTS AND NUTS WITH UNC OR UNF THREADS

- [5] PLUGS

- MAINTENANCE CHECK LIST

- CHECK AND MAINTENANCE

- [1] DAILY CHECK

- [2] CHECK POINTS OF INITIAL 50 HOURS

- [3] CHECK POINTS OF EVERY 50 HOURS

- [4] CHECK POINTS OF EVERY 100 HOURS

- [5] CHECK POINTS OF EVERY 200 HOURS

- [6] CHECK POINTS OF EVERY 400 HOURS

- [7] CHECK POINT OF EVERY 600 HOURS

- [8] CHECK POINT OF EVERY 800 HOURS

- [9] CHECK POINT OF EVERY 1500 HOURS

- [10] CHECK POINT OF EVERY 3000 HOURS

- [11] CHECK POINT OF EVERY 1 YEAR

- [12] CHECK POINTS OF EVERY 2 YEARS

- [13] OTHERS

- SPECIAL TOOLS

- [1] SPECIAL TOOLS FOR ENGINE

- [2] SPECIAL TOOLS FOR TRACTOR

- TIRES

- [1] TIRE PRESSURE

- [2] TREADS ADJUSTMENT

- (1) Front Wheel

- (2) Rear Wheels

- [3] TIRE LIQUID INJECTION

- [4] IMPLEMENT LIMITATIONS

- ENGINE

- MECHANISM

- ENGINE BODY

- [1] PISTON

- [2] HALF-FLOATING HEAD COVER

- FUEL SYSTEM

- [1] OUTLINE

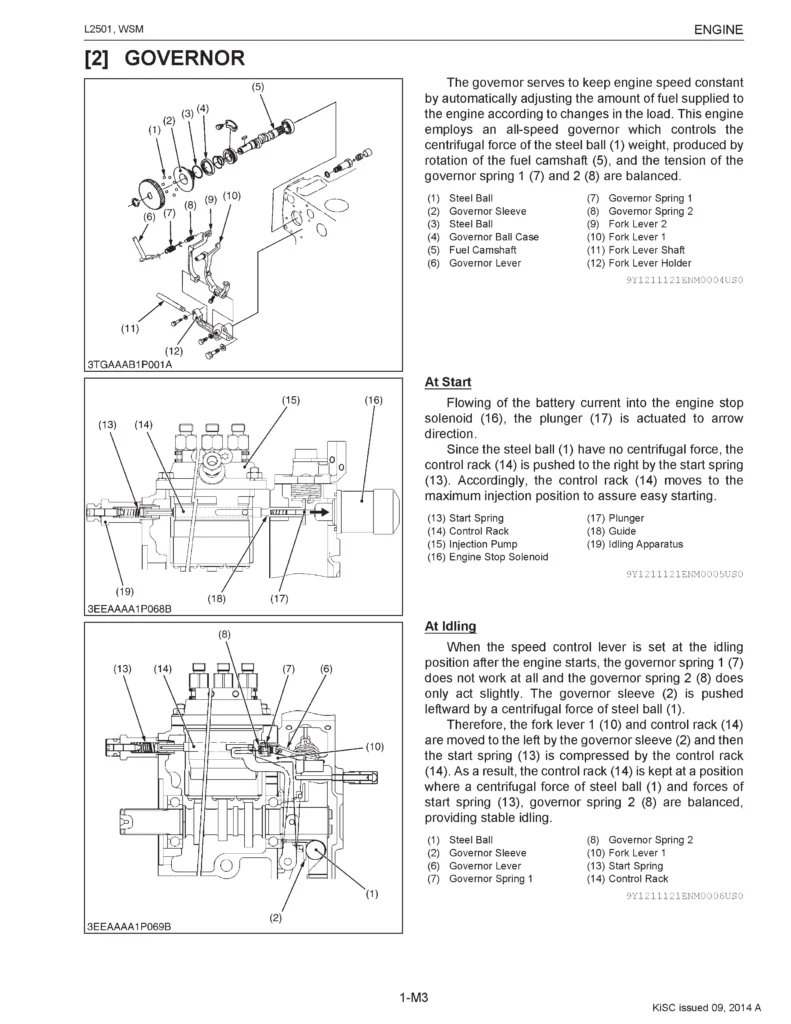

- [2] GOVERNOR

- [3] INJECTION NOZZLE

- COOLING SYSTEM

- SERVICING

- TROUBLESHOOTING

- SERVICING SPECIFICATIONS

- TIGHTENING TORQUES

- CHECKING AND ADJUSTING

- [1] ENGINE BODY

- [2] LUBRICATING SYSTEM

- [3] COOLING SYSTEM

- [4] FUEL SYSTEM

- PREPARATION

- [1] MANUAL TRANSMISSION TYPE

- (1) Separating Engine from Clutch Housing Case

- (2) Separating Engine from Front Axle Frame

- [2] HST TYPE

- (1) Separating Engine from Clutch Housing Case

- (2) Separating Engine from Front Axle Frame

- DISASSEMBLING AND ASSEMBLING

- [1] CYLINDER HEAD AND VALVES

- [2] TIMING GEARS, CAMSHAFT AND FUEL CAMSHAFT

- [3] CONNECTING ROD AND PISTON

- [4] CRANKSHAFT

- [5] THERMOSTAT

- SERVICING

- [1] CYLINDER HEAD AND VALVES

- [2] TIMING GEARS, CAMSHAFT AND FUEL CAMSHAFT

- [3] PISTON AND CONNECTING ROD

- [4] CRANKSHAFT

- [5] CYLINDER

- [6] OIL PUMP

- CLUTCH

- MECHANISM

- STRUCTURE

- SERVICING

- TROUBLESHOOTING

- SERVICING SPECIFICATIONS

- [1] SINGLE STAGE CLUTCH

- TIGHTENING TORQUES

- CHECKING AND ADJUSTING

- PREPARATION

- [1] SEPARATING CLUTCH HOUSING CASE FROM ENGINE

- (1) Manual Transmission Type

- (2) HST Type

- DISASSEMBLING AND ASSEMBLING

- [1] SINGLE STAGE CLUTCH

- SERVICING

- [1] SINGLE STAGE CLUTCH

- TRANSMISSION

- MECHANISM

- STRUCTURE

- [1] MANUAL TRANSMISSION TYPE

- [2] HST TYPE

- MANUAL TRANSMISSION TYPE

- [1] POWER TRAIN

- (1) Main Gear Shift Section (4 Speeds)

- (2) Range Gear Shift Section

- (3) Front Wheel Drive Section (4WD or 2WD)

- [2] SHIFT LINKAGE MECHANISM

- (1) Main Gear Shift Lever

- (2) Range Gear Shift Lever

- (3) Front Wheel Drive Lever (For Four Wheel Drive Model)

- [3] PTO SYSTEM

- (1) Structure

- (2) Shift Linkage

- HST TYPE

- [1] POWER TRAIN

- (1) Structure

- (2) Oil Flow

- (3) Operation

- (4) Range Gear Shift Section

- (5) Front Drive Wheel Section

- [2] HST PEDAL CONTROL LINKAGE

- [3] CRUISE CONTROL (OPTION)

- [4] SHIFT LINKAGE MECHANISM

- (1) Range Gear Shift Lever

- (2) Front Wheel Drive Lever

- [5] PTO SYSTEM

- (1) Structure

- (2) Shift Linkage

- SERVICING

- TROUBLESHOOTING

- [1] MANUAL TRANSMISSION TYPE

- [2] HST TYPE

- SERVICING SPECIFICATIONS

- [1] MANUAL TRANSMISSION TYPE

- [2] HST TYPE

- TIGHTENING TORQUES

- CHECKING AND ADJUSTING

- [1] MANUAL TRANSMISSION TYPE

- (1) Range Gear Shift Lever

- [2] HST TYPE

- PREPARATION

- [1] MANUAL TRANSMISSION TYPE

- (1) Separating Clutch Housing Case

- (2) Separating Transmission Case

- [2] HST TYPE

- (1) Separating Clutch Housing Case

- (2) Separating Mid Case

- (3) Separating Transmission Case

- DISASSEMBLING AND ASSEMBLING

- [1] MANUAL TRANSMISSION TYPE

- (1) Clutch Housing Case

- (2) Transmission Case

- (3) Disassembling Differential Gear Assembly

- [2] HST TYPE

- (1) Clutch Housing

- (2) Mid Case

- (3) Transmission Case

- (4) Disassembling Differential Gear Assembly

- (5) Disassembling Cruise Control (Option)

- SERVICING

- [1] CLUTCH HOUSING CASE

- (1) Manual Transmission Type

- (2) HST Type

- [2] TRANSMISSION CASE

- REAR AXLE

- MECHANISM

- STRUCTURE

- SERVICING

- TROUBLESHOOTING

- TIGHTENING TORQUES

- DISASSEMBLING AND ASSEMBLING

- [1] SEPARATING REAR AXLE CASE

- [2] DISASSEMBLING REAR AXLE

- SERVICING

- BRAKES

- MECHANISM

- FEATURES

- OPERATION

- SERVICING

- TROUBLESHOOTING

- SERVICING SPECIFICATIONS

- TIGHTENING TORQUES

- CHECKING AND ADJUSTING

- DISASSEMBLING AND ASSEMBLING

- [1] SEPARATING BRAKE CASE

- [2] DISASSEMBLING THE BRAKE CASE

- SERVICING

- FRONT AXLE

- MECHANISM

- STRUCTURE

- [1] 2WD

- [2] 4WD

- SERVICING

- TROUBLESHOOTING

- SERVICING SPECIFICATIONS

- TIGHTENING TORQUES

- CHECKING AND ADJUSTING

- DISASSEMBLING AND ASSEMBLING

- [1] SEPARATING FRONT AXLE

- [2] DISASSEMBLING FRONT AXLE

- (1) 2WD

- (2) 4WD

- SERVICING

- [1] 2WD

- [2] 4WD

- STEERING

- MECHANISM

- STRUCTURE

- HYDRAULIC CIRCUIT

- STEERING GEAR BOX

- [1] STRUCTURE

- [2] OPERATION

- SERVICING

- TROUBLESHOOTING

- SERVICING SPECIFICATIONS

- TIGHTENING TORQUES

- CHECKING AND ADJUSTING

- [1] STEERING WHEEL PLAY

- [2] STEERING GEAR BOX

- DISASSEMBLING AND ASSEMBLING

- [1] SEPARATING STEERING GEAR BOX

- [2] DISASSEMBLING GEAR BOX

- SERVICING

- HYDRAULIC SYSTEM

- MECHANISM

- STRUCTURE

- [1] MANUAL TRANSMISSION TYPE

- [2] HST TYPE

- HYDRAULIC CIRCUIT

- [1] MANUAL TRANSMISSION TYPE

- [2] HST TYPE

- THREE POINT HITCH HYDRAULIC SYSTEM

- [1] THREE POINT HITCH HYDRAULIC CIRCUIT

- [2] HYDRAULIC CYLINDER

- [3] LINKAGE MECHANISM

- [4] POSITION CONTROL VALVE

- [5] HYDRAULIC PUMP

- [6] SAFETY VALVE

- FRONT HYDRAULIC BLOCK

- [1] STRUCTURE

- [2] HYDRAULIC CIRCUIT

- [3] RELIEF VALVE

- SERVICING

- TROUBLESHOOTING

- SERVICING SPECIFICATIONS

- TIGHTENING TORQUES

- CHECKING AND ADJUSTING

- [1] RELIEF VALVE AND SAFETY VALVE

- [2] POSITION CONTROL ROD

- DISASSEMBLING AND ASSEMBLING

- [1] HYDRAULIC PUMP (THREE POINT HITCH HYDRAULIC SYSTEM)

- [2] HYDRAULIC CYLINDER

- [3] POSITION CONTROL VALVE

- [4] RELIEF VALVE

- SERVICING

- [1] HYDRAULIC PUMP (THREE POINT HITCH HYDRAULIC SYSTEM)

- [2] HYDRAULIC CYLINDER

- ELECTRICAL SYSTEM

- MECHANISM

- WIRING DIAGRAM

- [1] MANUAL TRANSMISSION TYPE

- [2] HST TYPE

- ELECTRICAL CIRCUIT

- [1] MANUAL TRANSMISSION TYPE

- [2] HST TYPE

- INSTRUMENT PANEL

- [1] INDICATION ITEMS OF METER PANEL

- [2] EASY CHECKER™

- ENGINE STARTING SYSTEM

- [1] ELECTRIC CIRCUIT

- (1) Manual Transmission Type

- (2) HST Type

- [2] SAFETY SWITCH

- (1) Manual Transmission Type

- (2) HST Type

- OPERATOR PRESENCE CONTROL (OPC) SYSTEM

- [1] ELECTRICAL CIRCUIT

- (1) Manual Transmission Type

- (2) HST Type

- [2] SAFETY SWITCH

- SERVICING

- TROUBLESHOOTING

- SERVICING SPECIFICATIONS

- TIGHTENING TORQUES

- CHECKING AND ADJUSTING

- [1] BATTERY

- [2] ENGINE STARTING AND STOPPING SYSTEM

- (1) Main Switch

- (2) Safety Switch

- (3) Starter and Starter Relay

- (4) Glow Control System

- (5) Engine Stop Solenoid

- (6) Operator Presence Control (OPC) System

- (7) Charging System

- (8) Fuse and Ground Cable

- [3] LIGHT SWITCHES AND FLASHER UNIT

- (1) Combination Switch

- (2) Hazard Switch

- (3) Flasher Unit

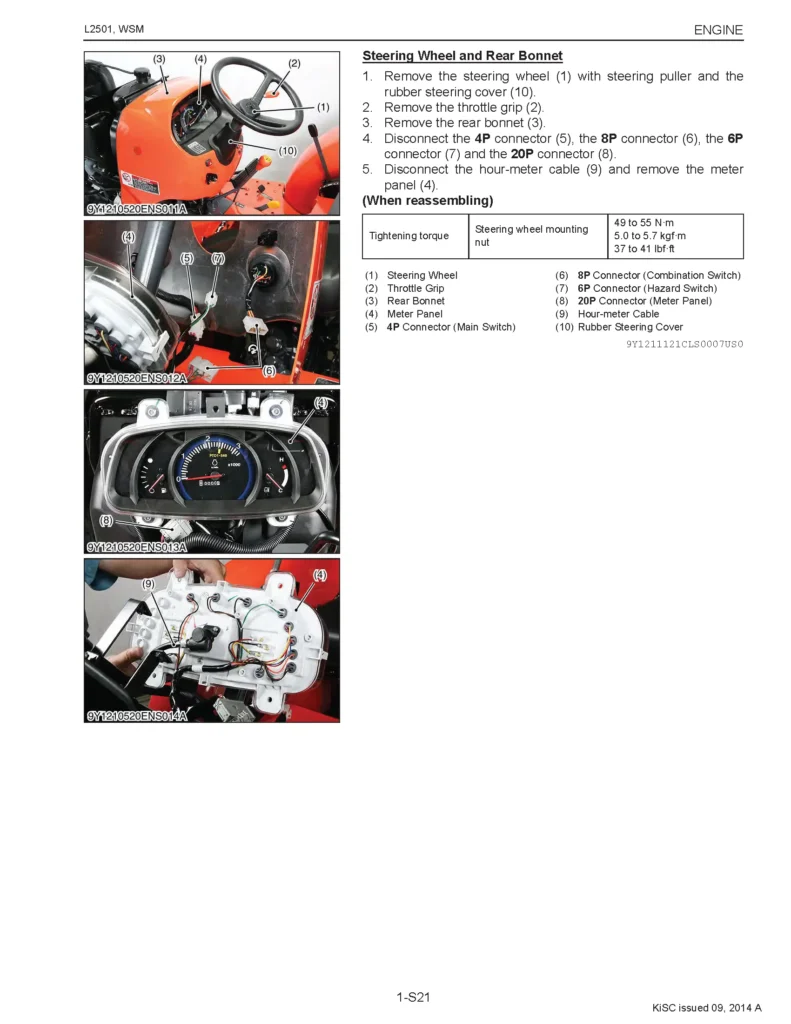

- [4] INSTRUMENT PANEL

- [5] GAUGES

- (1) Fuel Level Sensor

- (2) Coolant Temperature Sensor

- DISASSEMBLING AND ASSEMBLING

- [1] STARTER

- SERVICING

- [1] STARTER

Manual Info

- Format: PDF

- Pages: 444

- Download size: 13 MB

Delivery

The download link will be promptly delivered to your email upon completing the checkout process.

Abrites AVDI J2534

Abrites AVDI J2534 Actia Multi-Diag

Actia Multi-Diag Autoland iSCAN

Autoland iSCAN Bobcat Diagnostic Kit

Bobcat Diagnostic Kit BMW ENET

BMW ENET Bosch Mastertech II J2534

Bosch Mastertech II J2534 Bosch MTS 6531

Bosch MTS 6531 CAN CLIP RLT2002

CAN CLIP RLT2002 CarDAQ-Plus 3

CarDAQ-Plus 3 Cummins INLINE Datalink

Cummins INLINE Datalink Dearborn Protocol Adapter (DPA) 5

Dearborn Protocol Adapter (DPA) 5 Delphi/Autocom DS150E

Delphi/Autocom DS150E DrewLinQ

DrewLinQ Volvo VIDA DiCE

Volvo VIDA DiCE Derelek USB DIAG 3

Derelek USB DIAG 3 Electronic Data Link (EDL) 2

Electronic Data Link (EDL) 2 Electronic Data Link (EDL) 3

Electronic Data Link (EDL) 3 GM MDI 1

GM MDI 1 GM MDI 2

GM MDI 2 HEX-V2 VCDS VAG-COM

HEX-V2 VCDS VAG-COM Isuzu IDSS IDS MX1

Isuzu IDSS IDS MX1 Isuzu IDSS IDS MX2

Isuzu IDSS IDS MX2 Iveco Eltrac E.A.SY. ECI

Iveco Eltrac E.A.SY. ECI MaxiFlash Elite J2534

MaxiFlash Elite J2534 MB Star C6

MB Star C6 Mongoose J2534

Mongoose J2534 Nexiq USB-Link 1

Nexiq USB-Link 1 Nexiq USB-Link 2

Nexiq USB-Link 2 Nexiq USB-Link 3

Nexiq USB-Link 3 Noregon DLA+ 2.0

Noregon DLA+ 2.0 Porsche PIWIS TESTER 3 (PT3G)

Porsche PIWIS TESTER 3 (PT3G) PSA LEXIA 3

PSA LEXIA 3 SAE J2434

SAE J2434 Scania VCI 3

Scania VCI 3 Scanmatik 2 PRO

Scanmatik 2 PRO SD Connect Multiplexer

SD Connect Multiplexer Tactrix OpenPort 2.0

Tactrix OpenPort 2.0 Toyota TIS Mini VCI

Toyota TIS Mini VCI VAG ODIS VAS5054 Clone

VAG ODIS VAS5054 Clone VAG ODIS VAS6154 Clone

VAG ODIS VAS6154 Clone Volvo VOCOM 1

Volvo VOCOM 1 Volvo VOCOM 2

Volvo VOCOM 2 Xentry VCI

Xentry VCI Yanmar Diagnostic Interface Box (IFBOX)

Yanmar Diagnostic Interface Box (IFBOX)

Reviews

Clear filtersThere are no reviews yet.