The Audi A3 (8V) Running Gear, Axles, and Steering Workshop Manual is a comprehensive resource designed to help you maintain, repair, and optimize the performance of your vehicle’s running gear, axles, and steering systems. This manual provides detailed, step-by-step instructions, expert insights, and high-quality diagrams to ensure that every repair and maintenance task is performed to Audi’s exacting standards. Whether you’re a professional mechanic or a dedicated Audi enthusiast, this manual is essential for keeping your vehicle’s running gear and steering systems in peak condition.

Key Features:

- In-Depth Coverage: Comprehensive instructions for servicing and repairing the running gear, axles, and steering systems of the Audi A3 (8V).

- Step-by-Step Guidance: Clear, detailed procedures for performing everything from routine maintenance to complex repairs.

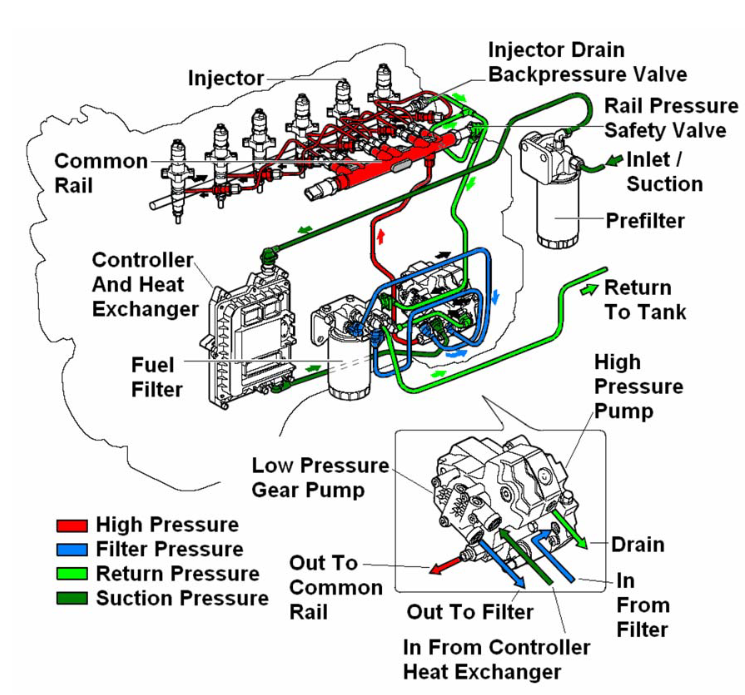

- High-Quality Diagrams: Precise illustrations that simplify complex processes and ensure accurate repairs.

- Expert Recommendations: Information provided by industry professionals to ensure reliable and safe repairs.

- OEM Standards: Ensure all repairs and adjustments meet Audi’s original specifications for safety and performance.

Format: PDF

Pages: 379

Delivery: The download link will be promptly delivered to your email upon completing the checkout process.

Covered Audi Vehicles:

- Audi A3 2013 ➤

- Audi A3 Cabriolet 2015 ➤

- Audi A3 Limousine 2014 ➤

- Audi A3 Limousine China 2014 ➤

- Audi A3 Sportback 2013 ➤

- Audi A3 Sportback China 2014 ➤

List of Workshop Manual Repair Groups:

- Technical data

- Front suspension

- Rear suspension

- Self-levelling suspension

- Wheels, tyres, vehicle geometry

- Steering

Contents:

- Technical data

- General notes

- Running gear

- Steering

- Types of tyre

- Safety precautions

- Safety precautions when working on vehicles with high-voltage system

- Safety precautions when working in the vicinity of high-voltage components

- Safety precautions when working on vehicles with start/stop system

- Safety precautions when using testers and measuring instruments during a road test

- Repair notes

- Leaks at shock absorbers

- Noises from shock absorbers

- Checking shock absorbers when removed

- Checking shock absorbers on shock tester

- Maximum values “a” in mm

- Rules for cleanliness

- General notes

- General repair instructions

- Contact corrosion

- Steering rack

- Gaskets and seals

- Bolts and nuts

- Electrical components

- Repair notes for drive shaft

- Repairing damaged threads in longitudinal member (subframe to body)

- Lifting suspension to unladen position – vehicles with coil springs

- Technical data

- Running gear

- Steering

- Disposal

- Releasing gas and draining front gas-filled shock absorbers

- Releasing gas and draining rear gas-filled shock absorbers

- General notes

- Front suspension

- Front axle

- Overview of fitting locations – front axle

- Subframe

- Exploded view – subframe

- Fixing position of subframe

- Lowering subframe

- Removing and installing subframe without steering rack

- Removing and installing subframe with steering rack

- Servicing subframe

- Removing and installing anti-roll bar

- Removing and installing coupling rod

- Suspension strut, upper wishbone

- Exploded view – suspension strut, upper wishbone

- Removing and installing suspension strut

- Servicing suspension strut

- Lowering suspension strut

- Lower wishbone, swivel joint

- Exploded view – lower wishbone, swivel joint

- Removing and installing lower wishbone

- Renewing bonded rubber bushes for lower wishbone

- Removing and installing swivel joint

- Wheel bearing

- Exploded view – wheel bearing

- Removing and installing wheel bearing housing

- Removing and installing wheel bearing unit

- Drive shaft

- Overview – drive shaft

- Exploded view – drive shaft

- Loosening and tightening bolt securing drive shaft

- Removing and installing heat shield for drive shaft

- Removing and installing drive shaft

- Dismantling and assembling drive shaft

- Checking outer constant velocity joint

- Checking inner constant velocity joint

- Front axle

- Rear suspension

- Rear axle

- Overview – rear axle

- Removing and installing rear axle

- Axle beam

- Exploded view – axle beam

- Renewing bonded rubber bushes for axle beam

- Subframe

- Exploded view – subframe

- Fixing position of subframe

- Servicing subframe

- Anti-roll bar

- Exploded view – anti-roll bar

- Removing and installing anti-roll bar

- Removing and installing coupling rod

- Suspension links, track rod

- Exploded view – transverse links

- Exploded view – track rod

- Removing and installing upper transverse link

- Removing and installing lower transverse link

- Removing and installing track rod

- Suspension strut/shock absorber, spring

- Exploded view – suspension strut/shock absorber, spring

- Removing and installing shock absorber

- Servicing shock absorber

- Removing and installing spring

- Wheel bearing, trailing arm

- Exploded view – wheel bearing

- Exploded view – trailing arm

- Removing and installing wheel bearing housing

- Removing and installing wheel bearing unit

- Renewing bonded rubber bush for wheel bearing housing

- Removing and installing trailing arm with mounting bracket

- Servicing trailing arm

- Drive shaft

- Overview – drive shaft

- Exploded view – drive shaft

- Loosening and tightening bolt securing drive shaft

- Removing and installing drive shaft

- Dismantling and assembling drive shaft

- Checking outer constant velocity joint

- Checking inner constant velocity joint

- Rear axle

- Self-levelling suspension

- Electronic damping control

- Exploded view – electronic damping control

- Removing and installing electronically controlled damping control unit J250

- Vehicle level senders

- Exploded view – front vehicle level senders

- Exploded view – rear vehicle level senders

- Removing and installing front vehicle level senders G78 / G289

- Removing and installing rear vehicle level senders G76 / G77

- Electronic damping control

- Wheels, tyres, vehicle geometry

- Wheels, tyres

- Wheel alignment

- Notes on wheel alignment

- When does wheel alignment have to be checked?

- Test requirements

- Preparations required before calibration of driver assist systems

- 5 Explanatory notes on production control numbers (PR numbers)

- 6 Preparations for measurement

- 7 Wheel runout compensation

- 8 Checking full steering lock

- Wheel alignment procedure

- Wheel alignment specifications

- Adjusting camber at front wheels

- Adjusting camber at rear wheels

- Adjusting toe setting at rear wheels

- Adjusting toe setting at front wheels

- Adaptive cruise control

- Adjusting adaptive cruise control

- Front camera for driver assist systems

- Calibrating front camera for driver assist systems

- Steering

- Steering wheel

- Exploded view – steering wheel

- Removing and installing steering wheel

- Steering column

- Exploded view – steering column

- Handling and transporting steering column

- Checking steering column for damage

- Removing and installing steering column

- Removing and installing control unit for electronic steering column lock J764

- Steering rack

- Exploded view – steering rack

- Servicing steering rack

- Handling and transporting steering rack

- Removing and installing steering rack

- Removing and installing boot

- Removing and installing track rod

- Removing and installing track rod ball joint

- Steering wheel

Reviews

Clear filtersThere are no reviews yet.