Unlock the full potential of your Hyundai Crawler Excavator R55-7 with this comprehensive Service, Repair, and Operating Manual. Designed to provide operators and technicians with step-by-step instructions for maintenance, troubleshooting, and repairs, this manual is an essential resource for ensuring your equipment operates at peak efficiency. Whether you’re performing routine service, handling repairs, or mastering the full range of operating features, this guide offers invaluable insights for the longevity and performance of your Hyundai excavator.

Key Features:

- Detailed repair and service procedures for the Hyundai R55-7 Crawler Excavator.

- In-depth operating instructions to help you maximize machine performance.

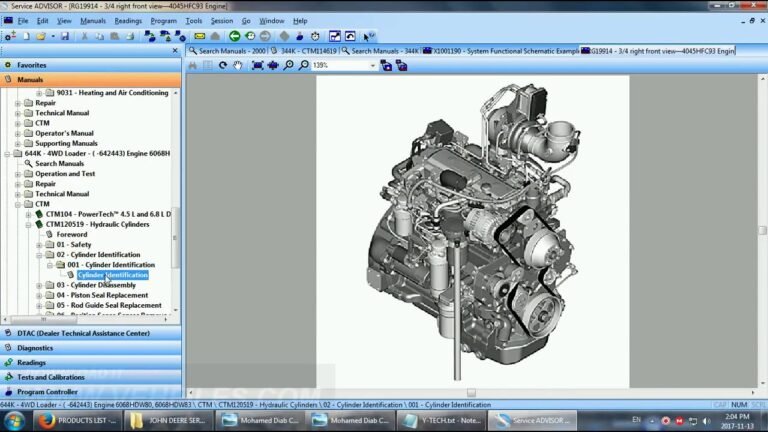

- Clear illustrations and diagrams for easy understanding of complex systems.

- Essential troubleshooting tips to resolve common issues efficiently.

- Complete maintenance schedules to keep your equipment in optimal condition.

- Designed for both professional technicians and owners to streamline repairs and upkeep.

Format: Interactive HTML

Delivery: The download link will be promptly delivered to your email upon completing the checkout process.

Operating Manual Content:

| Section | Group |

|---|---|

| SECTION 1 – SAFETY HINT | Group 1: Before operating the machine |

| Group 2: During operating the machine | |

| Group 3: During maintenance | |

| Group 4: Parking | |

| SECTION 2 – SPECIFICATIONS | Group 1: Major components |

| Group 2: Specifications | |

| Group 3: Working range | |

| Group 4: Weight | |

| Group 5: Lifting capacities | |

| Group 6: Bucket selection guide | |

| Group 7: Undercarriage | |

| Group 8: Specification for major components | |

| Group 9: Recommended oils | |

| SECTION 3 – CONTROL DEVICE | Group 1: Cab device |

| Group 2: Cluster | |

| Group 3: Switches | |

| Group 4: Levers and pedals | |

| Group 5: Air conditioner and heater | |

| Group 6: Others | |

| SECTION 4 – OPERATION | Group 1: Suggestion for new machine |

| Group 2: Check before starting the engine | |

| Group 3: Starting and stop the engine | |

| Group 4: Operation of the working device | |

| Group 5: Traveling of the machine | |

| Group 6: Efficient working method | |

| Group 7: Operation in the special work sites | |

| Group 8: Normal operation of excavator | |

| Group 9: Attachment lowering Pattern | |

| Group 10: Storage | |

| Group 11: RCV lever operating pattern | |

| SECTION 5 – TRANSPORTATION | Group 1: Preparation for transportation |

| Group 2: Dimension and weight | |

| Group 3: Loading the machine | |

| Group 4: Fixing the machine | |

| Group 5: Loading and unloading by crane | |

| SECTION 6 – MAINTENANCE | Group 1: Instructions |

| Group 2: Tightening torque | |

| Group 3: Specification of fuel, coolant and lubricants | |

| Group 4: Maintenance check list | |

| Group 5: Maintenance chart | |

| Group 6: Service instruction | |

| Group 7: Electrical system | |

| Group 8: Air conditioner and heater | |

| SECTION 7 – TROUBLESHOOTING GUIDE | Group 1: Engine |

| Group 2: Electrical system | |

| Group 3: Others | |

| SECTION 8 – HYDRAULIC BREAKER | Group 1: Selecting hydraulic breaker |

| Group 2: Circuit configuration | |

| Group 3: Maintenance | |

| Group 4: Precaution while operating the breaker | |

| Group 5: Quick clamp | |

| INDEX |

Service Manual Content:

| Section | Group |

|---|---|

| SECTION 1 – GENERAL | Group 1: Safety Hints |

| Group 2: Specifications | |

| SECTION 2 – STRUCTURE AND FUNCTION | Group 1: Pump Device |

| Group 2: Main Control Valve | |

| Group 3: Swing Device | |

| Group 4: Travel Motor | |

| Group 5: RCV Lever | |

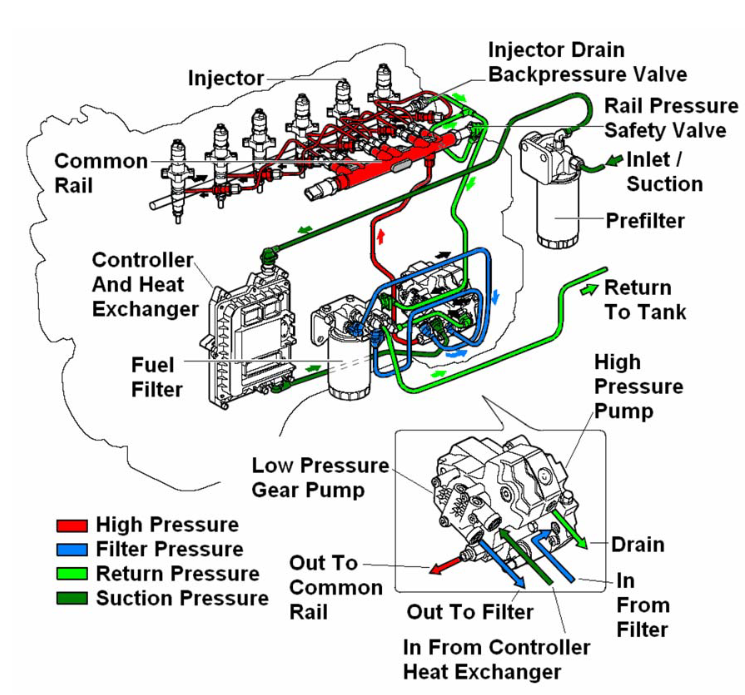

| SECTION 3 – HYDRAULIC SYSTEM | Group 1: Hydraulic Circuit |

| Group 2: Main Circuit | |

| Group 3: Pilot Circuit | |

| Group 4: Single Operation | |

| Group 5: Combined Operation | |

| SECTION 4 – ELECTRICAL SYSTEM | Group 1: Component Location |

| Group 2: Monitoring System | |

| Group 3: Electrical Circuit | |

| Group 4: Electrical Component Specification | |

| Group 5: Connectors | |

| SECTION 5 – TROUBLESHOOTING | Group 1: Before Troubleshooting |

| Group 2: Hydraulic and Mechanical System | |

| Group 3: Electrical System | |

| SECTION 6 – MAINTENANCE STANDARD | Group 1: Operating Performance Test |

| Group 2: Major Components | |

| Group 3: Track and Work Equipment | |

| SECTION 7 – DISASSEMBLY AND ASSEMBLY | Group 1: Precaution |

| Group 2: Tightening Torque | |

| Group 3: Pump Device | |

| Group 4: Main Control Valve | |

| Group 5: Swing Device | |

| Group 6: Travel Device | |

| Group 7: RCV Lever | |

| Group 8: Turning Joint | |

| Group 9: Boom, Arm, Bucket Cylinder | |

| Group 10: Undercarriage | |

| Group 11: Work Equipment | |

| SECTION 8 – COMPONENT MOUNTING TORQUE | Group 1: Introduction Guide |

| Group 2: Engine System | |

| Group 3: Electric System | |

| Group 4: Hydraulic System | |

| Group 5: Undercarriage | |

| Group 6: Structure | |

| Group 7: Work Equipment | |

| APPENDIX | |

| ENGINE SERVICE MANUAL | YANMAR INDUSTRIAL DIESEL ENGINE MODEL 3TNV/4TNV SERIES (Direct Injection System) |

| INJECTION PUMP SERVICE MANUAL | YANMAR FUEL INJECTION EQUIPMENT MODEL YPD-MP2/YPD-MP4 SERIES |

Reviews

Clear filtersThere are no reviews yet.