This manual explains the Controller Area Network (CAN-BUS) diagnostic principles used in CASE M-Series Dozers and other CNH Tier IV machines.

It introduces controller networking, voltage logic, and EST-based troubleshooting for CAN BUS 1 & 2 systems linking the ECM, UCM, AIC, Denox Module, and Telematics controllers.

Key learning points:

CAN BUS architecture: layout, twisted-pair topology, termination resistors (120 Ω), and node addressing.

Signal logic: CAN Hi (2.5–3.5 V DC) and CAN Lo (1.5–2.5 V DC).

EST testing procedures: voltage and resistance diagnosis, controller status interpretation, and fault isolation.

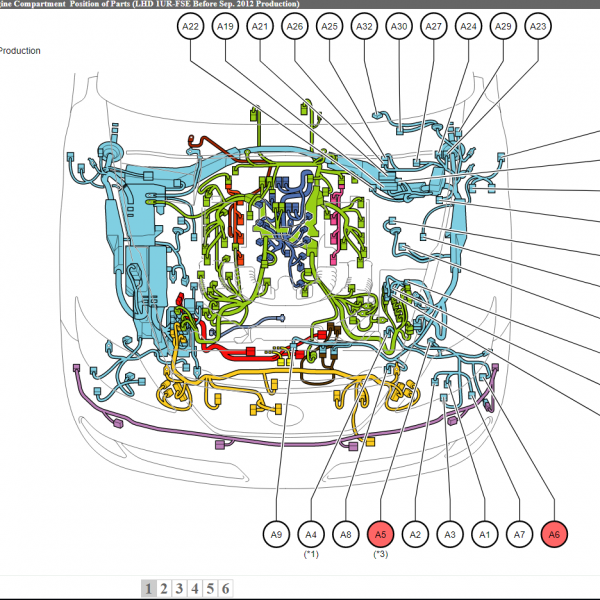

M-Series Dozer application: dedicated diagrams on pages 10–11 illustrate small and large dozer CAN BUS maps with diagnostic port placement.

Coverage

Introduction to CAN Technology

Origin (Bosch & Intel 1984)

Use in Automotive and Industrial applications

Purpose of CAN Systems

Replacing mechanical components with electronic modules

Networked communication for shared signals

Benefits of CAN

Reduced wiring and connectors

Improved diagnostics and sensor sharing

Enhanced reliability and signal accuracy

Terminology

ECU, EMC, BUS, CAN Hi/Lo voltage ranges, Terminator resistors

CAN Circuit Construction

Twisted pair wiring and magnetic field cancellation

Shielded vs unshielded configurations

Overview of CAN System

Digital message exchange between processors (page 5)

External and internal terminators illustration

Testing Procedures with EST and DVOM

Voltage test for good circuit (2.5–3.5 V range)

Offline controller diagnosis (shorted BUS)

Resistance test for termination integrity (60–30 Ω)

Short and open circuit fault examples

Troubleshooting Guide

Step-by-step fault isolation via controller disconnects

Interpretation of “ONLINE/OFFLINE” status on EST

M-Series Dozer CAN BUS Layouts

Small Dozer Network (UCM, AIC, Telematics, ECM)

Large Dozer Network with Denox Module and NOx sensor integration

Delivery

The download link will be sent to your email instantly after payment.

Abrites AVDI J2534

Abrites AVDI J2534 Actia Multi-Diag

Actia Multi-Diag Autoland iSCAN

Autoland iSCAN Bobcat Diagnostic Kit

Bobcat Diagnostic Kit BMW ENET

BMW ENET Bosch Mastertech II J2534

Bosch Mastertech II J2534 Bosch MTS 6531

Bosch MTS 6531 CAN CLIP RLT2002

CAN CLIP RLT2002 CarDAQ-Plus 3

CarDAQ-Plus 3 Cummins INLINE Datalink

Cummins INLINE Datalink Dearborn Protocol Adapter (DPA) 5

Dearborn Protocol Adapter (DPA) 5 Delphi/Autocom DS150E

Delphi/Autocom DS150E DrewLinQ

DrewLinQ Volvo VIDA DiCE

Volvo VIDA DiCE Derelek USB DIAG 3

Derelek USB DIAG 3 Electronic Data Link (EDL) 2

Electronic Data Link (EDL) 2 Electronic Data Link (EDL) 3

Electronic Data Link (EDL) 3 GM MDI 1

GM MDI 1 GM MDI 2

GM MDI 2 HEX-V2 VCDS VAG-COM

HEX-V2 VCDS VAG-COM Isuzu IDSS IDS MX1

Isuzu IDSS IDS MX1 Isuzu IDSS IDS MX2

Isuzu IDSS IDS MX2 Iveco Eltrac E.A.SY. ECI

Iveco Eltrac E.A.SY. ECI MaxiFlash Elite J2534

MaxiFlash Elite J2534 MB Star C6

MB Star C6 Mongoose J2534

Mongoose J2534 Nexiq USB-Link 1

Nexiq USB-Link 1 Nexiq USB-Link 2

Nexiq USB-Link 2 Nexiq USB-Link 3

Nexiq USB-Link 3 Noregon DLA+ 2.0

Noregon DLA+ 2.0 Porsche PIWIS TESTER 3 (PT3G)

Porsche PIWIS TESTER 3 (PT3G) PSA LEXIA 3

PSA LEXIA 3 SAE J2434

SAE J2434 Scania VCI 3

Scania VCI 3 Scanmatik 2 PRO

Scanmatik 2 PRO SD Connect Multiplexer

SD Connect Multiplexer Tactrix OpenPort 2.0

Tactrix OpenPort 2.0 Toyota TIS Mini VCI

Toyota TIS Mini VCI VAG ODIS VAS5054 Clone

VAG ODIS VAS5054 Clone VAG ODIS VAS6154 Clone

VAG ODIS VAS6154 Clone Volvo VOCOM 1

Volvo VOCOM 1 Volvo VOCOM 2

Volvo VOCOM 2 Xentry VCI

Xentry VCI Yanmar Diagnostic Interface Box (IFBOX)

Yanmar Diagnostic Interface Box (IFBOX)

Reviews

Clear filtersThere are no reviews yet.