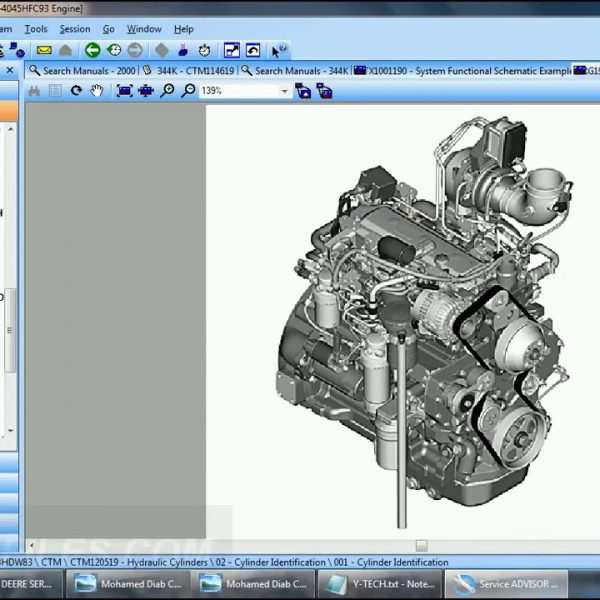

This manual covers the complete Electronic Service Tool (EST) functionality for FPT F5H Tier IV engines equipped with Cooled Exhaust Gas Recirculation (CEGR) and a Diesel Particulate Filter (DPF) system.

It details controller communication, data retrieval, programming, and reset procedures required for emissions-component servicing in CASE and New Holland equipment under 100 HP.

Key sections include:

DPF replacement and ash cleaning resets

Differential pressure, lambda, OxiCat, and PRV sensor resets

Engine dataset registration and injector coding

Forced DPF regeneration via EST controller tests

Anti-tampering dataset verification between ECU and VCM

Graphical screenshots throughout (see pages 6–27) illustrate each EST diagnostic interface, including Controller Status, Fault Retrieval, Monitor Parameters, and Injector Code Configuration

Coverage

Introduction

Tier IV Interim emission compliance overview

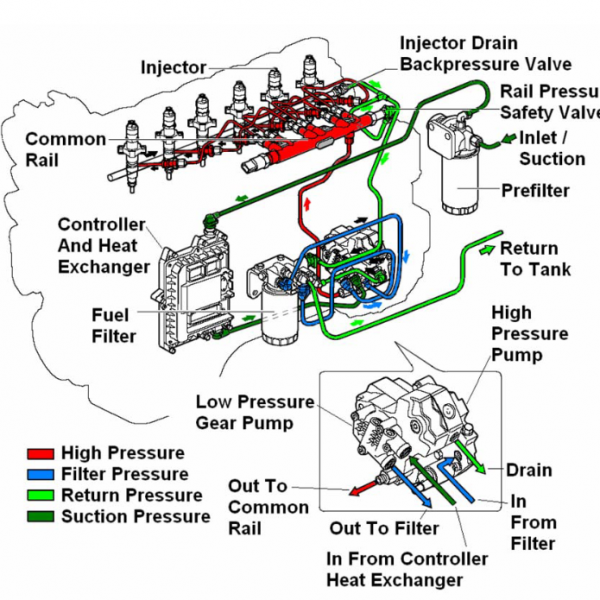

CEGR + DPF system description for F5H 4.2 L engines

Reset Functions (EST v7.2–7.4)

DPF replacement – ECU data reset

Differential pressure (Delta P) sensor reset

Engine oil / filter reminder reset

Lambda & OxiCat sensor reset

Rail pressure relief valve reset

EGR valve reset (added v7.3.0.0)

DPF ash cleaning reset (added v7.4.0.0)

Controller Status

CAN-bus connection verification

Hardware/software ID display

Retrieve Version Information function

Retrieve Controller Faults

Selected vs All controllers

Fault log export & print

Fault type mapping (1xxx VCM / 3xxx ECU / 4xxx TRAX)

Monitor Parameters

Live sensor value monitoring

Variable & digital parameter icons

Data logging and graph export setup

Programming Menu

Controller software download (ECU, VCM, TRAX)

Dataset file selection and validation

Post-program key-cycle procedure

Additional Tools

Accessing EASY Engine Diagnostic Tool

CAN parameter comparison and fault support

Configurations Icon

Model-specific parameter adjustments

Feature transfer for Tier IV N-series machines

Engine Dataset Registration

ECU ↔ VCM code matching and anti-tampering

Fault 3157/3158 resolution procedure

Injector Code Configuration

Injector code location and entry validation

7- and 10-digit examples for F5C & 13L engines

ECU update and storage confirmation

DPF and Oil Filter Replacement Resets

Algorithm reset logic for degradation tracking

VCM oil-life monitor integration

Controller Tests

Forced DPF Service Regeneration test

Safety precautions and temperature warnings

Status monitoring through EST interface

Delivery

The download link will be sent to your email instantly after payment.

Abrites AVDI J2534

Abrites AVDI J2534 Actia Multi-Diag

Actia Multi-Diag Autoland iSCAN

Autoland iSCAN Bobcat Diagnostic Kit

Bobcat Diagnostic Kit BMW ENET

BMW ENET Bosch Mastertech II J2534

Bosch Mastertech II J2534 Bosch MTS 6531

Bosch MTS 6531 CAN CLIP RLT2002

CAN CLIP RLT2002 CarDAQ-Plus 3

CarDAQ-Plus 3 Cummins INLINE Datalink

Cummins INLINE Datalink Dearborn Protocol Adapter (DPA) 5

Dearborn Protocol Adapter (DPA) 5 Delphi/Autocom DS150E

Delphi/Autocom DS150E DrewLinQ

DrewLinQ Volvo VIDA DiCE

Volvo VIDA DiCE Derelek USB DIAG 3

Derelek USB DIAG 3 Electronic Data Link (EDL) 2

Electronic Data Link (EDL) 2 Electronic Data Link (EDL) 3

Electronic Data Link (EDL) 3 GM MDI 1

GM MDI 1 GM MDI 2

GM MDI 2 HEX-V2 VCDS VAG-COM

HEX-V2 VCDS VAG-COM Isuzu IDSS IDS MX1

Isuzu IDSS IDS MX1 Isuzu IDSS IDS MX2

Isuzu IDSS IDS MX2 Iveco Eltrac E.A.SY. ECI

Iveco Eltrac E.A.SY. ECI MaxiFlash Elite J2534

MaxiFlash Elite J2534 MB Star C6

MB Star C6 Mongoose J2534

Mongoose J2534 Nexiq USB-Link 1

Nexiq USB-Link 1 Nexiq USB-Link 2

Nexiq USB-Link 2 Nexiq USB-Link 3

Nexiq USB-Link 3 Noregon DLA+ 2.0

Noregon DLA+ 2.0 Porsche PIWIS TESTER 3 (PT3G)

Porsche PIWIS TESTER 3 (PT3G) PSA LEXIA 3

PSA LEXIA 3 SAE J2434

SAE J2434 Scania VCI 3

Scania VCI 3 Scanmatik 2 PRO

Scanmatik 2 PRO SD Connect Multiplexer

SD Connect Multiplexer Tactrix OpenPort 2.0

Tactrix OpenPort 2.0 Toyota TIS Mini VCI

Toyota TIS Mini VCI VAG ODIS VAS5054 Clone

VAG ODIS VAS5054 Clone VAG ODIS VAS6154 Clone

VAG ODIS VAS6154 Clone Volvo VOCOM 1

Volvo VOCOM 1 Volvo VOCOM 2

Volvo VOCOM 2 Xentry VCI

Xentry VCI Yanmar Diagnostic Interface Box (IFBOX)

Yanmar Diagnostic Interface Box (IFBOX)

Reviews

Clear filtersThere are no reviews yet.