This comprehensive guide covers the entire UDST procedure — from setup conditions to fault interpretation. It details how to evaluate SCR system integrity, detect blockages, assess pump and injector behavior, and diagnose issues such as air ingress, leaks, and failed evacuations. The manual also includes hydraulic schematics, DCU control logic, pressure thresholds, and diagnostic routines like System Emptying and Flushing. A complete list of failure scenarios, pressure thresholds, and corrective actions is provided with supporting graphs and visuals.

Coverage

Fundamentals

Urea Dosing System Test overview

Test purpose and limitations

Static test prerequisites

Diagnostic routines in EST

Test Setup & Location

Accessing UDST in CNH EST

Engine conditions before testing

Using EASY ENGINE vs Base EST

UDST Procedure

Step-by-step EST operation

Test sequence and expected duration

PASS/FAIL interpretation

Troubleshooting navigation

Evaluation and Parameters

Pump speed test (1800–3600 rpm)

System pressure range (4900–6200 mbar)

Throttle test evaluation (1500–4300 mbar differential)

Injection verification (≤100 mbar differential)

Emptying pressure range (−300 to −50 mbar)

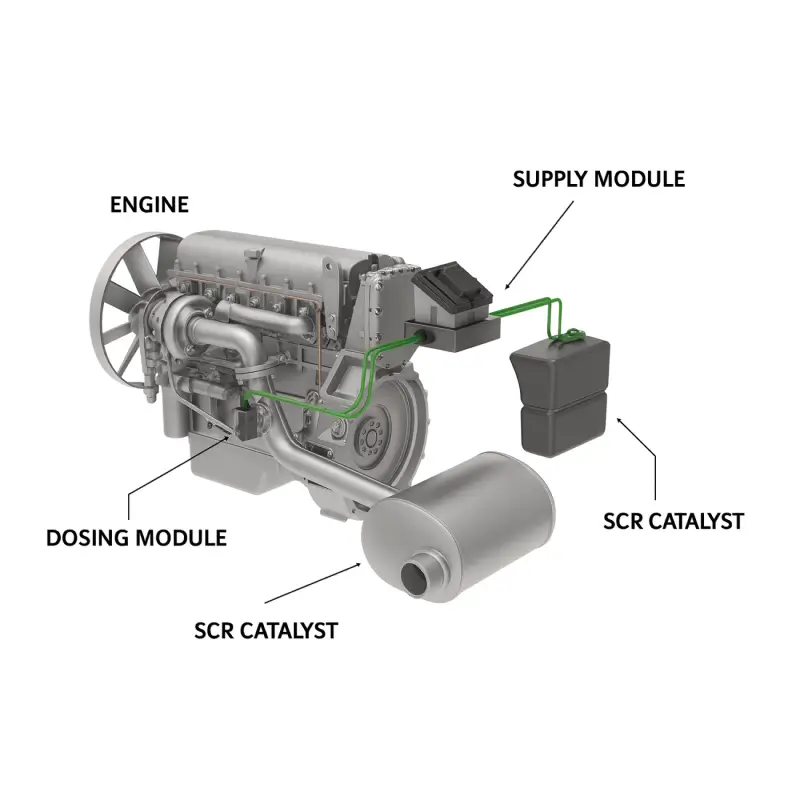

SCR System Review

DEF flow diagram

Main components overview (tank, injector, supply module, sensors)

NOx reduction process

Cooling and heater control systems

Supply Module Details

Bosch Denoxtronic SM layout

Pressure control and reverting valve operation

Sensor mapping and filtering system

Dosing Module (Injector)

Pressure regulation

Check valve design

Evacuation and return flow path

Hydraulic Schematics

DEF pressure circuit (5 bar nominal)

Cooling and circulation loop

Emptying and reverting operation sequence

DNOx Function Stages

Pressure build-up phase

Reverting valve check

Normal dosing operation

Afterrun evacuation logic

Maintenance & Repair Routines

Flushing routine

System emptying validation

Data saving and report exporting

Fault code interpretation (DCU15)

Failure Scenarios

Air in system

Low DEF injection

High-pressure leaks

Reverting valve malfunction

Pump or pressure buildup failure

Clogged lines and incorrect tubing configuration

Delivery

The download link will be sent to your email instantly after payment.

Abrites AVDI J2534

Abrites AVDI J2534 Actia Multi-Diag

Actia Multi-Diag Autoland iSCAN

Autoland iSCAN Bobcat Diagnostic Kit

Bobcat Diagnostic Kit BMW ENET

BMW ENET Bosch Mastertech II J2534

Bosch Mastertech II J2534 Bosch MTS 6531

Bosch MTS 6531 CAN CLIP RLT2002

CAN CLIP RLT2002 CarDAQ-Plus 3

CarDAQ-Plus 3 Cummins INLINE Datalink

Cummins INLINE Datalink Dearborn Protocol Adapter (DPA) 5

Dearborn Protocol Adapter (DPA) 5 Delphi/Autocom DS150E

Delphi/Autocom DS150E DrewLinQ

DrewLinQ Volvo VIDA DiCE

Volvo VIDA DiCE Derelek USB DIAG 3

Derelek USB DIAG 3 Electronic Data Link (EDL) 2

Electronic Data Link (EDL) 2 Electronic Data Link (EDL) 3

Electronic Data Link (EDL) 3 GM MDI 1

GM MDI 1 GM MDI 2

GM MDI 2 HEX-V2 VCDS VAG-COM

HEX-V2 VCDS VAG-COM Isuzu IDSS IDS MX1

Isuzu IDSS IDS MX1 Isuzu IDSS IDS MX2

Isuzu IDSS IDS MX2 Iveco Eltrac E.A.SY. ECI

Iveco Eltrac E.A.SY. ECI MaxiFlash Elite J2534

MaxiFlash Elite J2534 MB Star C6

MB Star C6 Mongoose J2534

Mongoose J2534 Nexiq USB-Link 1

Nexiq USB-Link 1 Nexiq USB-Link 2

Nexiq USB-Link 2 Nexiq USB-Link 3

Nexiq USB-Link 3 Noregon DLA+ 2.0

Noregon DLA+ 2.0 Porsche PIWIS TESTER 3 (PT3G)

Porsche PIWIS TESTER 3 (PT3G) PSA LEXIA 3

PSA LEXIA 3 SAE J2434

SAE J2434 Scania VCI 3

Scania VCI 3 Scanmatik 2 PRO

Scanmatik 2 PRO SD Connect Multiplexer

SD Connect Multiplexer Tactrix OpenPort 2.0

Tactrix OpenPort 2.0 Toyota TIS Mini VCI

Toyota TIS Mini VCI VAG ODIS VAS5054 Clone

VAG ODIS VAS5054 Clone VAG ODIS VAS6154 Clone

VAG ODIS VAS6154 Clone Volvo VOCOM 1

Volvo VOCOM 1 Volvo VOCOM 2

Volvo VOCOM 2 Xentry VCI

Xentry VCI Yanmar Diagnostic Interface Box (IFBOX)

Yanmar Diagnostic Interface Box (IFBOX)

Reviews

Clear filtersThere are no reviews yet.