Comprehensive workshop manual for Audi A3 (8V) covering technical data, engine maintenance, and safety precautions. Perfect for mechanics and car enthusiasts.

Format: PDF

Pages: 706

Delivery: The download link will be promptly delivered to your email upon completing the checkout process.

Covered Audi Vehicles:

- Audi A3 2013 ➤

- Audi A3 Sportback China 2014 ➤

Covered Engine IDs: CMBA, CPTA, CJZA, CXSA, CXSB, CSSA, CYVB, CZCA, CZEA, CUKB, CXUA, DBWA, CWLA, CZCC, DJSA, DGEA

List of Workshop Manual Repair Groups:

- Technical data

- Removing and installing engine

- Crankshaft group

- Cylinder head, valve gear

- Lubrication

- Cooling

- Turbocharging/supercharging

- Mixture preparation – injection

- Exhaust system

- Ignition system

- Electric drive systems

Contents:

- Technical data

- Identification

- Engine number/engine data

- Safety precautions

- Safety precautions when working on vehicles with high-voltage system

- Safety precautions when working in the vicinity of high-voltage components

- Safety precautions when working on the fuel supply system

- Safety precautions when working on vehicles with start/stop system

- Safety precautions when using testers and measuring instruments during a road test

- Safety precautions when working on the ignition system

- Safety precautions when working on the cooling system

- Safety precautions when working on the exhaust system

- Assessing high-voltage system risk level

- Necessary qualifications

- Work that requires high-voltage system to be de-energised

- Repair instructions

- Work on high-voltage components or potential equalisation lines

- Rules for cleanliness

- Foreign particles in engine

- Contact corrosion

- Routing and attachment of pipes, hoses and wiring

- Nuts, bolts

- Identification plates

- Use of impact wrenches

- Installing radiators and condensers

- Checking vacuum system

- General notes

- Painting work on vehicles with high-voltage system

- Removing and installing engine

- Removing and installing engine

- Removing engine

- Separating engine and gearbox

- Securing engine to engine and gearbox support

- Installing engine

- Assembly mountings

- Exploded view – assembly mountings

- Supporting engine in installation position

- Removing and installing engine mountings

- Removing and installing gearbox mounting

- Removing and installing pendulum support

- Checking adjustment of assembly mountings (engine/gearbox mountings)

- Adjusting assembly mountings

- Engine cover panel

- Removing and installing engine cover panel

- Crankshaft group

- Cylinder block (pulley end)

- Exploded view – poly V-belt drive

- Exploded view – sealing flange (pulley end)

- Plug for “TDC” drilling in cylinder block – tightening torque

- Removing and installing poly V-belt

- Removing and installing tensioner for poly V-belt

- Removing and installing engine support

- Removing and installing pulley

- Renewing crankshaft oil seal (pulley end)

- Removing and installing sealing flange (pulley end)

- Cylinder block (gearbox end)

- Exploded view – cylinder block (gearbox end)

- Removing and installing flywheel

- Removing and installing sealing flange (gearbox end)

- Crankshaft

- Crankshaft dimensions

- Measuring axial clearance of crankshaft

- Renewing needle bearing in crankshaft

- Pistons and conrods

- Exploded view – pistons and conrods

- Removing and installing pistons

- Removing and installing oil spray jets

- Checking pistons and cylinder bores

- Checking radial clearance of conrod bearings

- Cylinder head, valve gear

- Toothed belt drive

- Exploded view – toothed belt cover

- Exploded view – toothed belt

- Detaching toothed belt from camshaft

- Removing and installing toothed belt

- Cylinder head

- Exploded view – cylinder head

- Removing and installing cylinder head

- Removing and installing camshaft housing

- Checking compression

- Valve gear

- Exploded view – valve gear

- Removing and installing cam actuators

- Removing and installing camshaft control valve 1 N205

- Measuring axial clearance of camshaft

- Removing and installing camshaft oil seal

- Removing and installing valve stem oil seals

- Inlet and exhaust valves

- Checking valve guides

- Checking valves

- Valve dimensions

- Lubrication

- Sump/oil pump

- Exploded view – sump/oil pump

- Removing and installing oil level and oil temperature sender G266

- Removing and installing sump

- Removing and installing oil pump

- Engine oil

- Engine oil cooler

- Exploded view – engine oil cooler

- Removing and installing engine oil cooler

- Crankcase breather

- Exploded view – crankcase breather system

- Removing and installing oil separator

- Oil filter/oil pressure switches

- Exploded view – oil filter/oil pressure switches

- Removing and installing oil pressure switch F22

- Removing and installing oil pressure switch F1 / F378

- Removing and installing valve for oil pressure control N428

- Checking oil pressure

- Cooling

- Cooling system/coolant

- Connection diagram – coolant hoses

- Checking cooling system for leaks

- Draining and filling cooling system

- Connecting coolant hose with plug-in connector

- Coolant expansion tank

- Exploded view – coolant expansion tank

- Removing and installing coolant expansion tank

- Coolant pump/thermostat assembly

- Exploded view – coolant pump/thermostat

- Exploded view – electric coolant pump

- Exploded view – coolant temperature senders

- Exploded view – coolant valves

- Removing and installing coolant pump

- Removing and installing toothed belt sprocket for coolant pump

- Removing and installing thermostat

- Removing and installing electric coolant pump

- Removing and installing coolant temperature sender G62

- Removing and installing radiator outlet coolant temperature sender G83

- Removing and installing coolant temperature sender for heater G241

- Removing and installing engine temperature sender 2 G652

- Removing and installing coolant valves

- Coolant pipes

- Exploded view – coolant pipes

- Removing and installing coolant pipes

- Radiators/radiator fan

- Exploded view – radiators/radiator fan

- Exploded view – radiator cowl and radiator fan

- Removing and installing radiator

- Removing and installing radiator cowl

- Removing and installing radiator fan

- Turbocharging/supercharging

- Turbocharger

- Exploded view – turbocharger

- Removing and installing turbocharger

- Renewing vacuum unit for turbocharger

- Removing and installing charge pressure positioner V465

- Removing and installing connection for turbocharger

- Charge air system

- Exploded view – charge air system

- Exploded view – hose connections for charge air system

- Removing and installing charge pressure sender G31 / intake air temperature sender 2 G299

- Removing and installing charge air cooler

- Mixture preparation – injection

- Injection system

- Overview of fitting locations – injection system

- Air cleaner

- Exploded view – air cleaner housing

- Removing and installing air cleaner housing

- Intake manifold

- Exploded view – intake manifold

- Removing and installing intake manifold

- Removing and installing throttle valve module GX3

- Cleaning throttle valve module GX3

- Removing and installing activated charcoal filter solenoid valve 1 N80

- Injectors

- Exploded view – fuel rail with injectors

- Removing and installing fuel rail

- Removing and installing injectors

- Cleaning injectors

- Senders and sensors

- Removing and installing intake air temperature sender G42 / intake manifold pressure sender G71

- Removing and installing fuel pressure sender G247

- Checking fuel pressure sender G247

- Removing and installing pressure differential sender for particulate filter G1037

- High-pressure pump

- Exploded view – high-pressure pump

- Removing and installing high-pressure pump

- Removing and installing high-pressure pipe

- Lambda probe

- Exploded view – Lambda probe

- Removing and installing Lambda probe

- Engine control unit

- Removing and installing engine/motor control unit J623

- Exhaust system

- Exhaust pipes/silencers

- Exploded view – silencers

- Removing and installing silencers

- Separating exhaust pipes/silencers

- Stress-free alignment of exhaust system

- Checking exhaust system for leaks

- Emission control system

- Exploded view – emission control system

- Exploded view – retainers and pipes for pressure differential sender for particulate filter G1037

- Removing and installing catalytic converter

- Removing and installing particulate filter

- Exhaust gas temperature control

- Exploded view – exhaust gas temperature control

- Removing and installing parts of exhaust gas temperature control

- Secondary air system

- Exploded view – secondary air system

- Removing and installing secondary air pump motor V101

- Removing and installing sender 1 for secondary air pressure G609

- Ignition system

- Ignition system

- Exploded view – ignition system

- Test data – spark plugs

- Removing and installing ignition coils

- Removing and installing knock sensor 1 G61

- Removing and installing Hall senders

- Removing and installing engine speed sender G28

- Electric drive systems

- High-voltage components

- Overview of fitting locations – high-voltage components

- Checking high-voltage components and high-voltage wiring

- Warning labels

- Checking warning labels

- High-voltage battery unit

- Exploded view – high-voltage battery

- Inspection and classification of hybrid battery unit AX1

- Removing and installing hybrid battery unit AX1

- Performing leak test for high-voltage battery

- Checking for high-voltage battery leaks

- Raising high-voltage battery

- Storing and transporting high-voltage batteries

- Removing and installing battery regulation control unit J840

- Repairing high-voltage battery

- Overview of fitting locations – high-voltage battery

- Overview of fitting locations – battery modules

- Overview of fitting locations – high-voltage connecting brackets

- Exploded view – battery housing

- Exploded view – switching unit for high-voltage battery SX6

- Exploded view – battery module assembly

- Exploded view – traction network connector mounting

- Exploded view – high-voltage battery cooling system

- Performing leak test on cooling system for hybrid battery unit AX1

- Determining mean cell voltage

- Charging and discharging battery modules

- Opening hybrid battery unit AX1

- Removing and installing switching unit for high-voltage battery SX6

- Removing and installing battery module assembly

- Removing and installing traction network connector mounting

- Removing and installing coolant temperature sender 1 for high-voltage battery G898 and coolant temperature sender 2 for high-voltage battery G899

- Bonding hybrid battery unit AX1

- Removing and installing battery module 1 J991 / battery module 2 J992

- Removing and installing battery module 3 J993 / battery module 4 J994

- Removing and installing battery module 5 J995 / battery module 6 J996

- Removing and installing battery module 7 J997 / battery module 8 J998

- Power and control electronics for electric drive

- Exploded view – power and control electronics for electric drive

- Exploded view – bracket for power and control electronics for electric drive

- Removing and installing power and control electronics for electric drive

- Removing and installing bracket for power and control electronics for electric drive JX1

- Removing and installing high-voltage system fuse 3 S353

- Charging unit for high-voltage battery

- Exploded view – charging unit for high-voltage battery

- Removing and installing charging unit 1 for high-voltage battery AX4

- Removing and installing bracket for charging unit 1 for high-voltage battery AX4

- Electric drive motor

- Removing and installing three-phase current drive VX54

- Removing and installing drive motor temperature sender G712

- Removing and installing drive motor rotor position sender 1 G713

- High-voltage wiring

- Overview of fitting locations – high-voltage wires

- Removing and installing high-voltage wiring harness for high-voltage battery

- Removing and installing high-voltage wiring harness for drive motor

- Removing and installing high-voltage wire for power and control electronics for electric drive

- Removing and installing high-voltage wire for high-voltage heater (PTC)

- Removing and installing high-voltage wire for electrical air conditioner compressor

- Charging socket

- Exploded view – charging socket

- e-tron charging system

- USB adapter for e-tron charging system

- Removing and installing high-voltage battery charging socket 1 UX4

- De-energising high-voltage system

- Re-energising high-voltage system

- Potential equalisation lines

- General notes – potential equalisation lines

- Overview of fitting locations – potential equalisation lines

- Removing and installing potential equalisation lines

- Engine sound generation

- Overview of fitting locations – engine sound generation

- Removing and installing engine sound generator control unit J943

- Removing and installing actuator 1 for engine sound generator R257

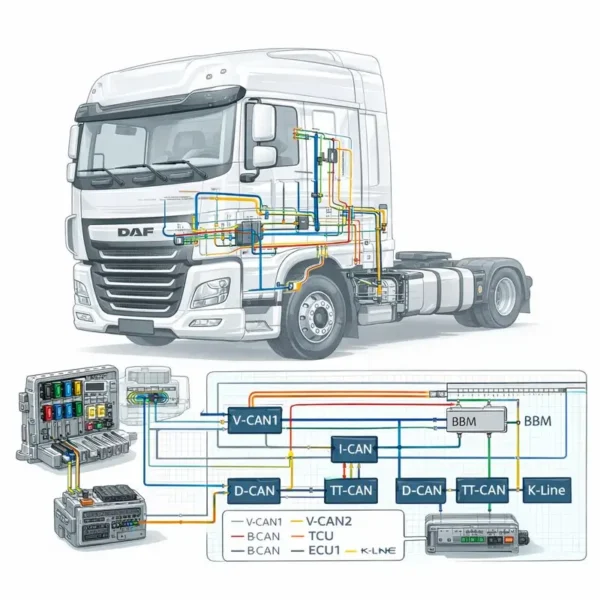

Abrites AVDI J2534

Abrites AVDI J2534 Actia Multi-Diag

Actia Multi-Diag Autoland iSCAN

Autoland iSCAN Bobcat Diagnostic Kit

Bobcat Diagnostic Kit BMW ENET

BMW ENET Bosch Mastertech II J2534

Bosch Mastertech II J2534 Bosch MTS 6531

Bosch MTS 6531 CAN CLIP RLT2002

CAN CLIP RLT2002 CarDAQ-Plus 3

CarDAQ-Plus 3 Cummins INLINE Datalink

Cummins INLINE Datalink Dearborn Protocol Adapter (DPA) 5

Dearborn Protocol Adapter (DPA) 5 Delphi/Autocom DS150E

Delphi/Autocom DS150E DrewLinQ

DrewLinQ Volvo VIDA DiCE

Volvo VIDA DiCE Derelek USB DIAG 3

Derelek USB DIAG 3 Electronic Data Link (EDL) 2

Electronic Data Link (EDL) 2 Electronic Data Link (EDL) 3

Electronic Data Link (EDL) 3 GM MDI 1

GM MDI 1 GM MDI 2

GM MDI 2 HEX-V2 VCDS VAG-COM

HEX-V2 VCDS VAG-COM Isuzu IDSS IDS MX1

Isuzu IDSS IDS MX1 Isuzu IDSS IDS MX2

Isuzu IDSS IDS MX2 Iveco Eltrac E.A.SY. ECI

Iveco Eltrac E.A.SY. ECI MaxiFlash Elite J2534

MaxiFlash Elite J2534 MB Star C6

MB Star C6 Mongoose J2534

Mongoose J2534 Nexiq USB-Link 1

Nexiq USB-Link 1 Nexiq USB-Link 2

Nexiq USB-Link 2 Nexiq USB-Link 3

Nexiq USB-Link 3 Noregon DLA+ 2.0

Noregon DLA+ 2.0 Porsche PIWIS TESTER 3 (PT3G)

Porsche PIWIS TESTER 3 (PT3G) PSA LEXIA 3

PSA LEXIA 3 SAE J2434

SAE J2434 Scania VCI 3

Scania VCI 3 Scanmatik 2 PRO

Scanmatik 2 PRO SD Connect Multiplexer

SD Connect Multiplexer Tactrix OpenPort 2.0

Tactrix OpenPort 2.0 Toyota TIS Mini VCI

Toyota TIS Mini VCI VAG ODIS VAS5054 Clone

VAG ODIS VAS5054 Clone VAG ODIS VAS6154 Clone

VAG ODIS VAS6154 Clone Volvo VOCOM 1

Volvo VOCOM 1 Volvo VOCOM 2

Volvo VOCOM 2 Xentry VCI

Xentry VCI Yanmar Diagnostic Interface Box (IFBOX)

Yanmar Diagnostic Interface Box (IFBOX)

Reviews

Clear filtersThere are no reviews yet.