Electronic Engines Service Manual WorkShop for NEF 445TA and 667TA TIER 3 Case-New Holland (CNH ) Engines.

Language: English

Format: PDF

Pages: 120

Table of content:

- CASE NEF ENGINE CHART 5

- NEW HOLLAND NEF ENGINE CHART 9

- ENGINES INTRODUCTION 15

- ENGINE IDENTIFICATION CODE 17

- GENERAL INFORMATION: ENGINE F4 18

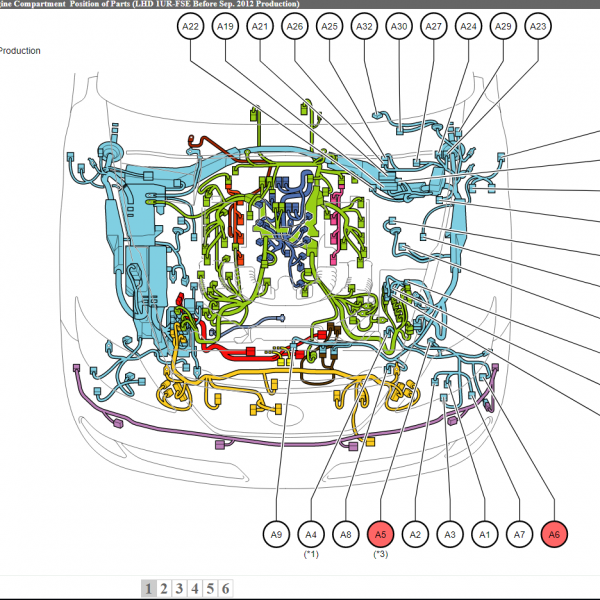

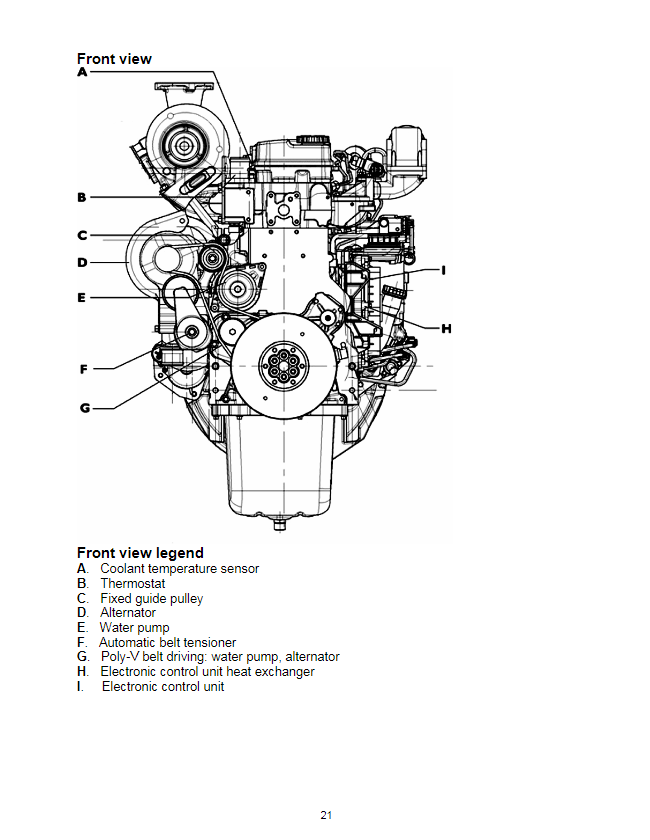

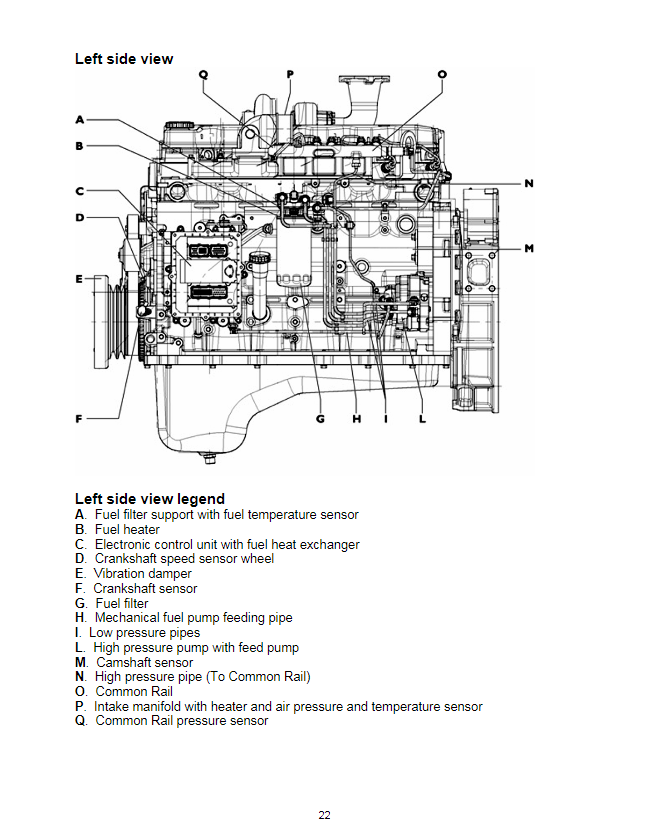

- ENGINE WALK AROUND 19

- GENERAL F4 (4 CYLINDER) ENGINE FEATURES 24

- GENERAL F4 (6 CYLINDER) ENGINE FEATURES 26

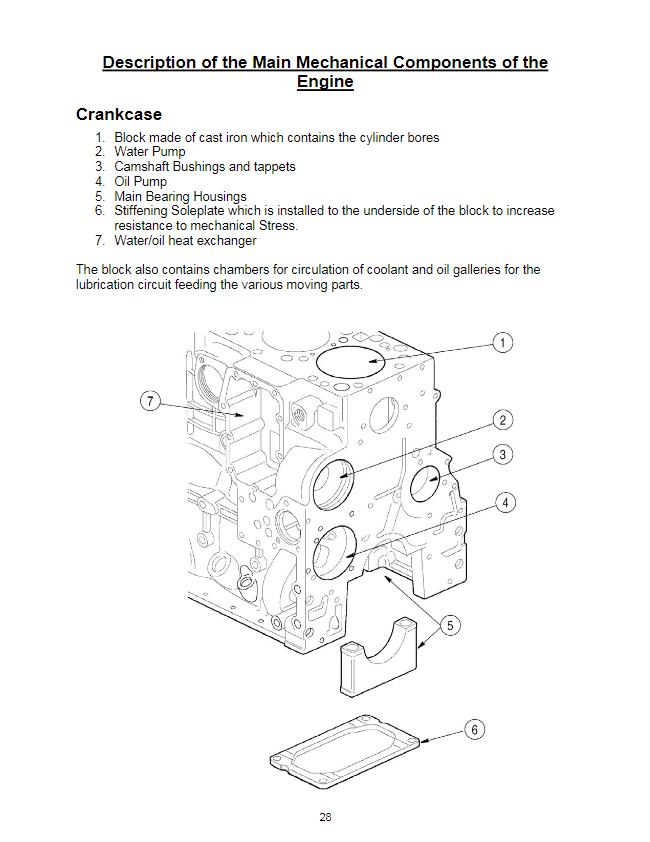

- DESCRIPTION OF THE MAIN MECHANICAL COMPONENTS OF THE ENGINE 28

- CRANKCASE 28

- CRANKSHAFT 28

- CRANKSHAFT 29

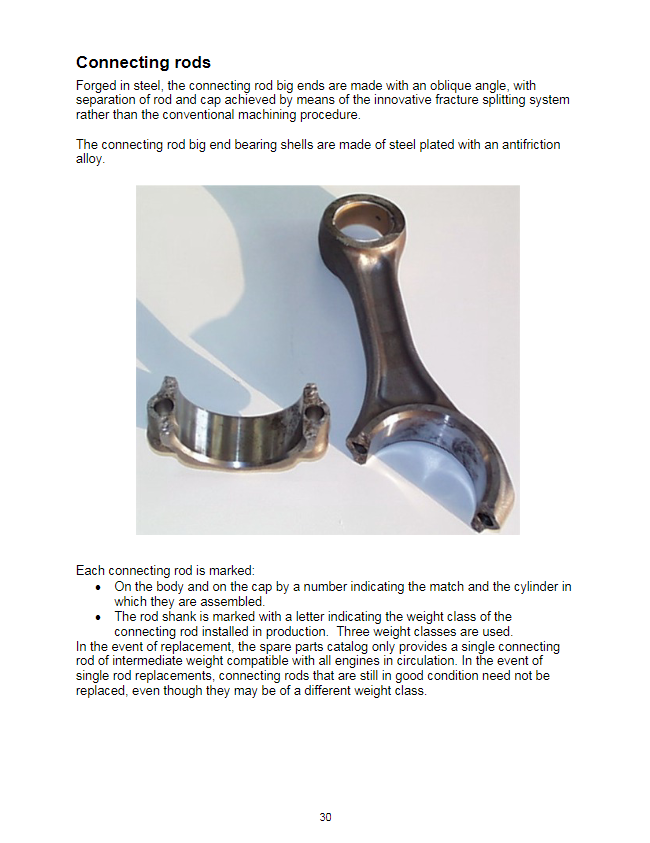

- CONNECTING RODS 29

- CONNECTING RODS 30

- PISTONS 31

- CAMSHAFT 31

- CAMSHAFT 32

- EGR Exhaust Gas Recirculation System 33

- VALVE TRAIN 34

- CYLINDER HEAD 35

- VALVES AND VALVE SEATS 36

- VALVE GUIDES 37

- VALVE CONTROL BRIDGES 37

- LOCATING TOP DEAD CENTER FOR 4CYLINDER ENGINES 38

- Adjusting Valve Play for a 4 Cylinder Engine 39

- LOCATING TOP DEAD CENTER FOR 6CYLINDER ENGINES 40

- Adjusting Valve Play for a 6 Cylinder Engine 41

- HEAD MACHINING 42

- TIMING GEARS 43

- ENGINE FLYWHEEL 44

- ACCESSORY EQUIPMENT DRIVE 45

- Poly-V belt removal 45

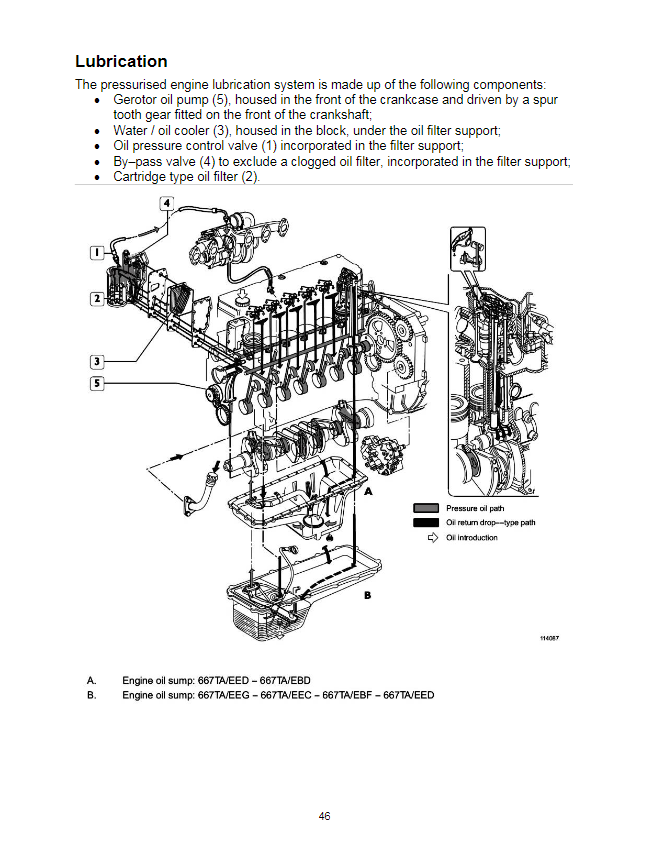

- LUBRICATION 46

- Engine Oil Cooler 46

- Engine Oil Cooler 47

- Oil pump 47

- Oil pump 48

- Sump (Suspended Oil Pan) 48

- Sump (Suspended Oil Pan) 49

- Conventional Sump (Oil Pan) 50

- Blow-By Recirculation 51

- COOLING 52

- Water pump 53

- Thermostat 53

- TURBOCHARGER 54

- HIGH PRESSURE ELECTRONIC INJECTION SYSTEM (COMMON RAIL) 55

- ELECTRICAL COMPONENTS 56

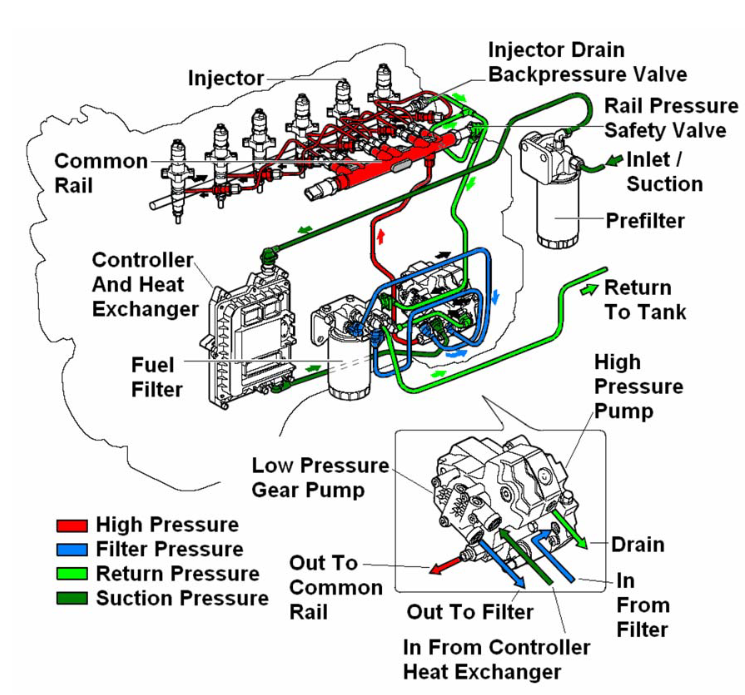

- HYDRAULIC COMPONENTS –COMMON RAIL SYSTEM 573

- FUEL SYSTEM DIAGRAM GENERAL 58

- FUEL SUPPLY SYSTEM DIAGRAM F4HEENGINES 59

- NORMAL OPERATION:(FUEL FLOW) 60

- MAIN MECHANICAL COMPONENTS OF THE FUEL SUPPLY SYSTEM 62

- Fuel Pre-filter 62

- Fuel filter 63

- Gear Charge Feed Pump 64

- Fuel System Bleeding 66

- High Pressure Pump 67

- Operating principle 69

- High Pressure Regulator 72

- Common Rail (Pressure accumulator) 75

- Common rail pressure relief valve 76

- Electro Injector 77

- Fuel High Pressure Connector 80

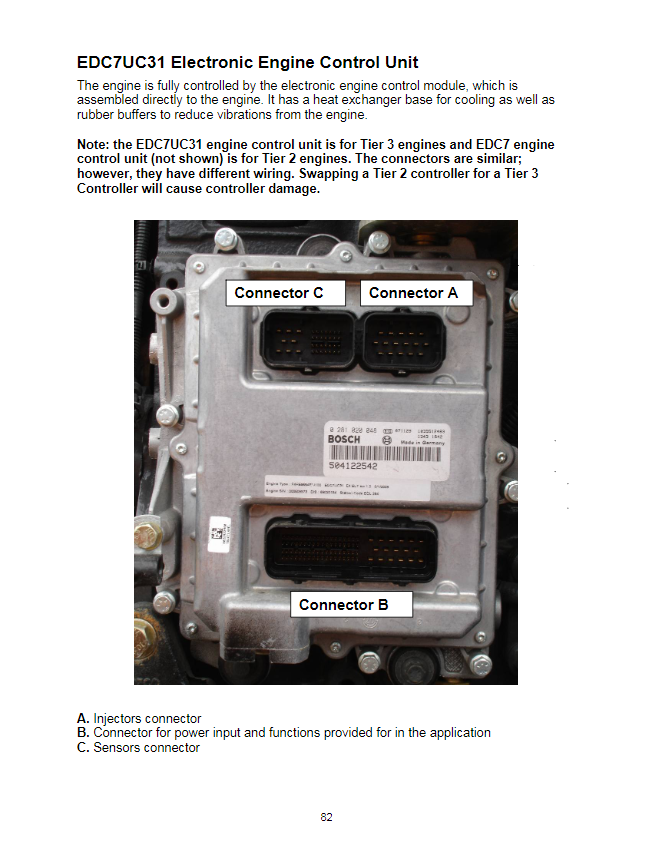

- EDC7UC31 SYSTEM MAIN ELECTRICAL AND ELECTRONIC COMPONENTS 81

- EDC7UC31ELECTRONIC ENGINE CONTROL UNIT 82

- Connector Pin Out 83

- Connector (A) – Injectors 84

- Sensors connector (C) 85

- EDC7UC31 ENGINE ELECTRONIC CONTROL PARAMETERS 86

- LIMP HOME RECOVERY STRATEGIES 88

- ENGINE DEGRADATION IN CNH APPLICATIONS – NEF TIER 2 (EXAMPLE) 89

- ENGINE DEGRADATION IN CNH APPLICATIONS – NEF TIER 3 (EXAMPLE) 90

- SENSORS 91

- SPECIAL TOOLS 99

- NEW ENGINE FAMILY (NEF) FUEL SUPPLY / LEAKAGE TEST KIT – 380140055 101

- NEW ENGINE FAMILY (NEF;FAMILY III)–MECHANICAL FUEL SYSTEMS 102

- Section 1: Mechanical Fuel System Description 102

- Section 2: Fuel Leaks at the Advance Piston Cover 103

- Section 3: Fuel Inlet Restriction / Air Entering System 104

- NEW ENGINE FAMILY (NEF;FAMILY III)–ELECTRONIC FUEL SYSTEMS 108

- Section 4: Electronic Fuel System Description 109

- Section 5: Fuel Inlet Restriction / Air Entering System 111

- Section 6: Low Pressure Pump Testing 115

- Section 7: Pressure Relief Valve Testing 117

- Section 8: High Pressure Flow Regulator 118

- Section 9: Fuel Injectors 119

Delivery: The download link will be sent to your email instantly after payment.

Abrites AVDI J2534

Abrites AVDI J2534 Actia Multi-Diag

Actia Multi-Diag Autoland iSCAN

Autoland iSCAN Bobcat Diagnostic Kit

Bobcat Diagnostic Kit BMW ENET

BMW ENET Bosch Mastertech II J2534

Bosch Mastertech II J2534 Bosch MTS 6531

Bosch MTS 6531 CAN CLIP RLT2002

CAN CLIP RLT2002 CarDAQ-Plus 3

CarDAQ-Plus 3 Cummins INLINE Datalink

Cummins INLINE Datalink Dearborn Protocol Adapter (DPA) 5

Dearborn Protocol Adapter (DPA) 5 Delphi/Autocom DS150E

Delphi/Autocom DS150E Volvo VIDA DiCE

Volvo VIDA DiCE Derelek USB DIAG 3

Derelek USB DIAG 3 Electronic Data Link (EDL) 2

Electronic Data Link (EDL) 2 Electronic Data Link (EDL) 3

Electronic Data Link (EDL) 3 GM MDI 1

GM MDI 1 GM MDI 2

GM MDI 2 HEX-V2 VCDS VAG-COM

HEX-V2 VCDS VAG-COM Isuzu IDSS IDS MX1

Isuzu IDSS IDS MX1 Isuzu IDSS IDS MX2

Isuzu IDSS IDS MX2 Iveco Eltrac E.A.SY. ECI

Iveco Eltrac E.A.SY. ECI MaxiFlash Elite J2534

MaxiFlash Elite J2534 Mongoose J2534

Mongoose J2534 Nexiq USB-Link 1

Nexiq USB-Link 1 Nexiq USB-Link 2

Nexiq USB-Link 2 Nexiq USB-Link 3

Nexiq USB-Link 3 Noregon DLA+ 2.0

Noregon DLA+ 2.0 Porsche PIWIS TESTER 3 (PT3G)

Porsche PIWIS TESTER 3 (PT3G) PSA LEXIA 3

PSA LEXIA 3 SAE J2434

SAE J2434 Scania VCI 3

Scania VCI 3 Scanmatik 2 PRO

Scanmatik 2 PRO SD Connect Multiplexer

SD Connect Multiplexer Tactrix OpenPort 2.0

Tactrix OpenPort 2.0 Toyota TIS Mini VCI

Toyota TIS Mini VCI VAG ODIS VAS5054 Clone

VAG ODIS VAS5054 Clone VAG ODIS VAS6154 Clone

VAG ODIS VAS6154 Clone Volvo VOCOM 1

Volvo VOCOM 1 Volvo VOCOM 2

Volvo VOCOM 2

Reviews

Clear filtersThere are no reviews yet.