Cummins Engine (ISBe/ISB/QSB) Common Rail Fuel System Service Manual Volume II with high-quality graphics and illustrations.

Format: Interactive PDF

Pages: 898

Delivery: The download link will instantly be sent to your email after checkout.

Coverage:

- ISBe

- ISB

- QSB

- About the Manual

- General Information

- Acronyms and Abbreviations

- General Information

- General Cleaning Instructions

- Abrasive Pads and Abrasive Paper

- Definition of Clean

- Fuel System

- Gasket Surfaces

- Plastic Bead Cleaning

- Solvent and Acid Cleaning

- Steam Cleaning

- General Repair Instructions

- General Information

- Welding on a Vehicle with an Electronic Controlled Fuel System

- General Safety Instructions

- Important Safety Notice

- How to Use the Manual

- General Information

- Illustrations

- General Information

- Symbols

- General Information

- EFC Actuator Valve

- Finishing Steps

- Initial Check

- Install

- Measure

- Preparatory Steps

- Remove

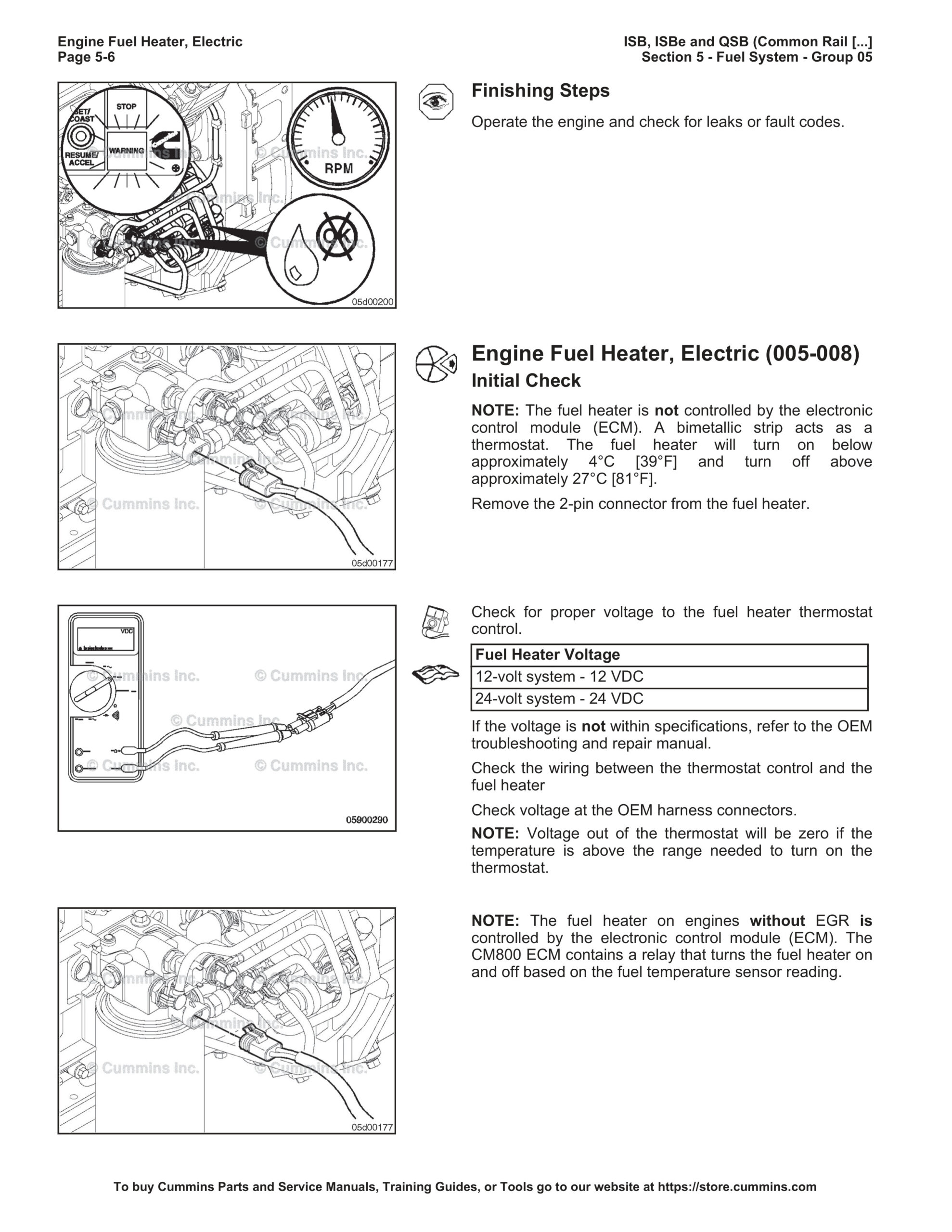

- Engine Fuel Heater, Electric

- Initial Check

- Install

- Remove

- Fuel Consumption

- Measure

- Fuel Lift Pump

- Finishing Steps

- Initial Check

- Install

- Measure

- Preparatory Steps

- Prime

- Remove

- Fuel Pump

- Assemble

- Clean and Inspect for Reuse

- Disassemble

- Finishing Steps

- General Information

- Install

- Preparatory Steps

- Prime

- Remove

- Test

- Service Tools

- Fuel System

- Stall Speed Test

- Stall Speed Check

- Stall Speed Checklist

- Time Speed Check

- Air in Fuel

- General Information

- Test

- ECM Cooling Plate, Fuel Cooled

- Assemble

- Clean and Inspect for Reuse

- Disassemble

- Finishing Steps

- General Information

- Initial Check

- Install

- Preparatory Steps

- Prime

- Remove

- Fuel Connector (Head Mounted)

- Clean and Inspect for Reuse

- Finishing Steps

- General Information

- Install

- Preparatory Steps

- Remove

- Fuel Cooler

- Clean and Inspect for Reuse

- Finishing Steps

- Install

- Preparatory Steps

- Remove

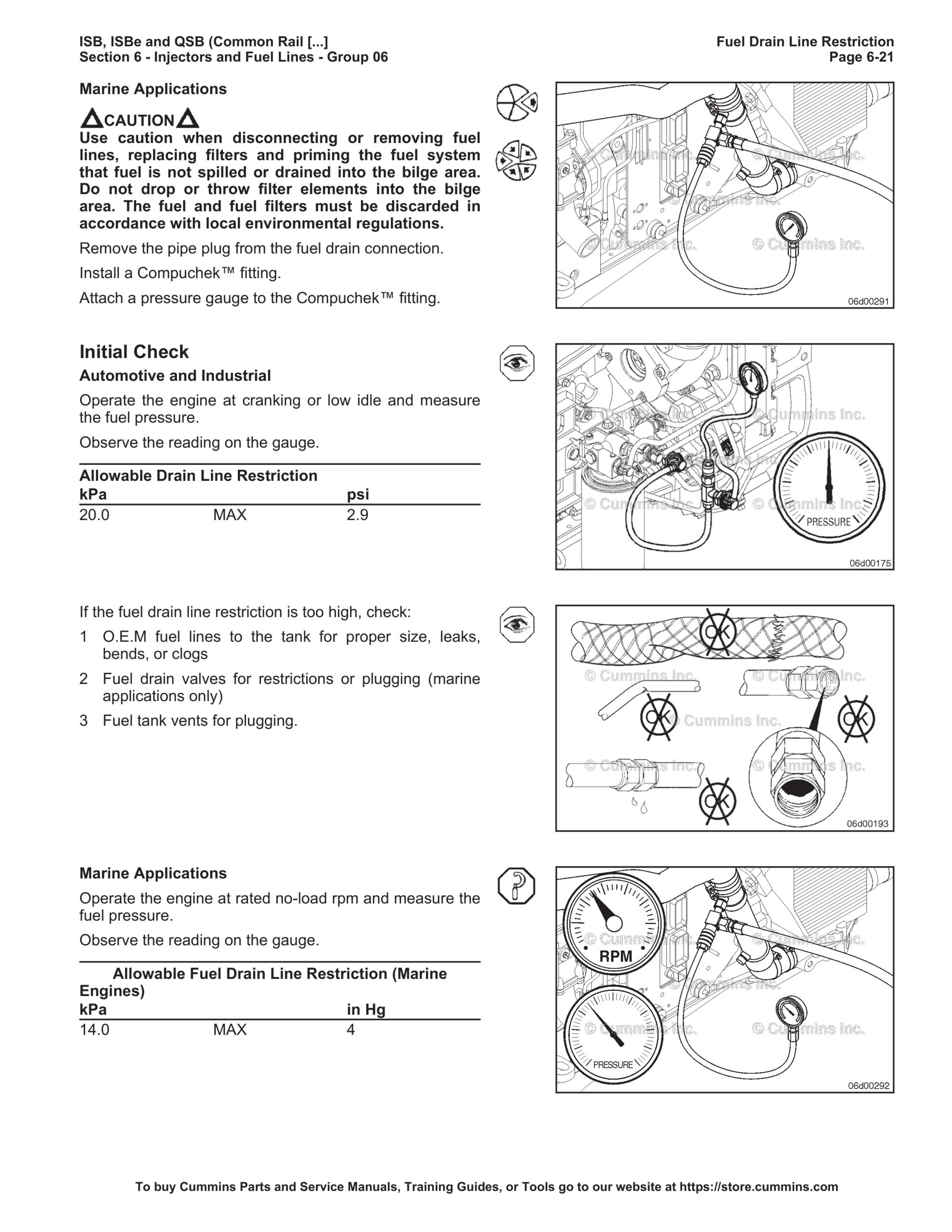

- Fuel Drain Line Restriction

- General Information

- Initial Check

- Setup

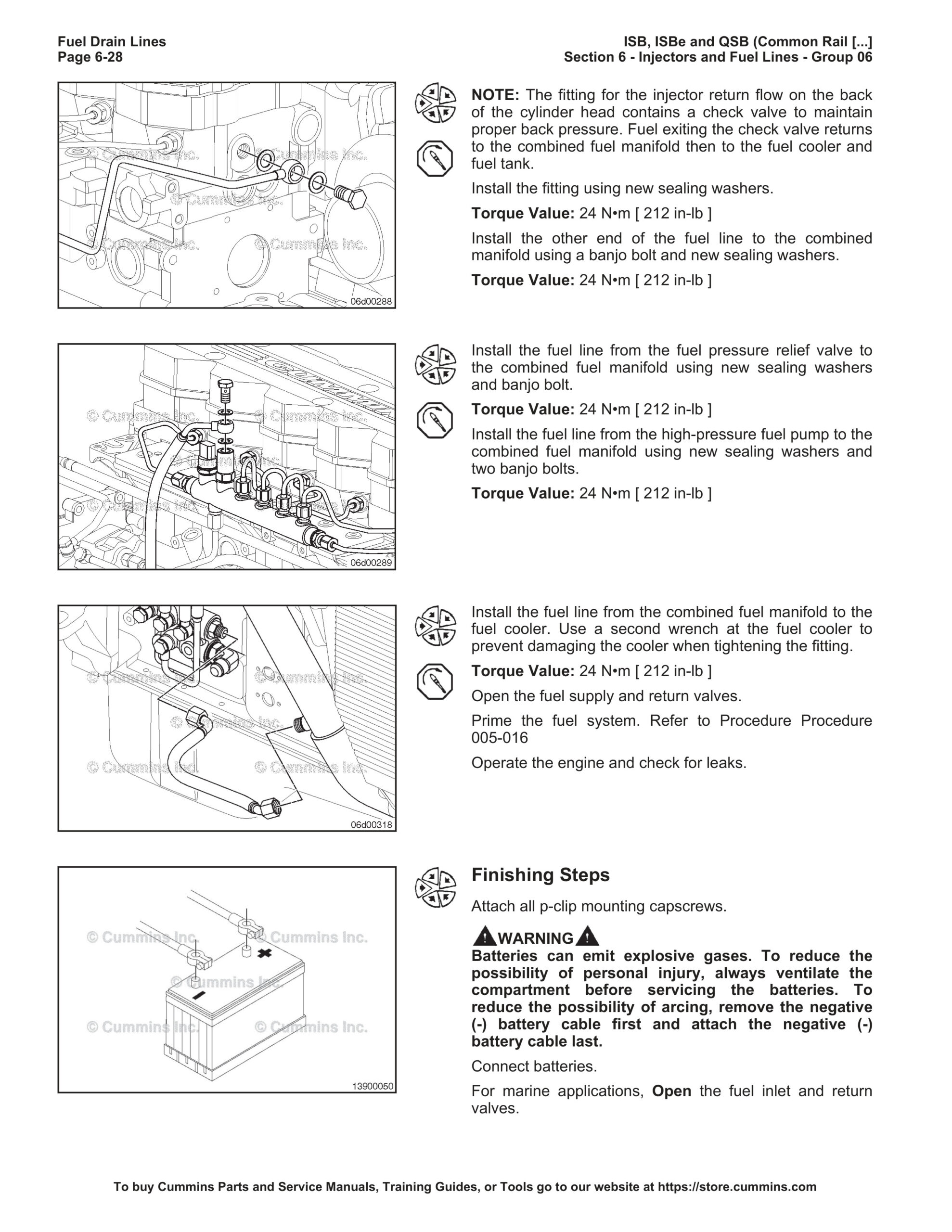

- Fuel Drain Lines

- Finishing Steps

- General Information

- Initial Check

- Inspect for Reuse

- Install

- Preparatory Steps

- Remove

- Fuel Filter (Spin-On Type)

- General Information

- Initial Check

- Install

- Prime

- Remove

- Setup

- Fuel Filter Head

- Assemble

- Automotive and Industrial

- Marine Applications

- Clean and Inspect for Reuse

- Disassemble

- Automotive and Industrial

- Marine Applications

- General Information

- Install

- Low Mount Fuel Filter

- High Mount Fuel Filter

- Marine Applications

- Preparatory Steps

- Prime

- With Electric Lift Pump

- Without Electric Lift Pump

- Marine Applications

- Remove

- Low Mount Fuel Filter

- High Mount Fuel Filter

- Marine Applications

- Fuel Filter Head Bracket

- Assemble

- Disassemble

- Inspect for Reuse

- Install

- Remove

- Fuel Inlet Restriction

- General Information

- Initial Check

- Prime

- Setup

- Fuel Manifold (Combined)

- Assembly

- Disassemble

- Finishing Steps

- Inspect for Reuse

- Install

- Preparatory Steps

- Remove

- Fuel Pressure Relief Valve

- Finishing Steps

- General Information

- Initial Check

- Install

- Preparatory Steps

- Prime

- Remove

- Setup

- Test

- Fuel Rail

- Clean and Inspect for Reuse

- Finishing Steps

- General Information

- Initial Check

- Install

- Preparatory Steps

- Remove

- Fuel Return Overflow Valve

- Clean

- Initial Check

- Inspect for Reuse

- Install

- Remove

- Fuel Supply Lines

- Clean and Inspect for Reuse

- Finishing Steps

- General Information

- Initial Check

- Install

- Preparatory Steps

- Prime

- Remove

- Injector

- Clean and Inspect for Reuse

- Finishing Steps

- General Information

- Initial Check

- Install

- Preparatory Steps

- Remove

- Setup

- Test

- Injector Supply Lines (High Pressure)

- Finishing Steps

- General Information

- Initial Check

- Inspect for Reuse

- Install

- Remove

- Service Tools

- Injectors and Fuel Lines

- Engine Oil Heater

- Clean and Inspect for Reuse

- Finishing Steps

- Install

- Preparatory Steps

- Remove

- Test

- Lubricating Oil and Filter Analysis

- Inspect

- Lubricating Oil Contamination

- General Information

- Lubricating Oil Cooler

- Clean and Inspect for Reuse

- Finishing Steps

- General Information

- Install

- Leak Test

- Preparatory Steps

- Remove

- Lubricating Oil Dipstick

- Calibrate

- Lubricating Oil Dipstick Tube

- Finishing Steps

- Install

- Preparatory Steps

- Remove

- Lubricating Oil Filter (Spin-On)

- Finishing Steps

- Install

- Remove

- Lubricating Oil Filter Head (Remote Mounted)

- Assemble

- Disassemble

- Finishing Steps

- Inspect for Reuse

- Install

- Preparatory Steps

- Remove

- Lubricating Oil Filter Head Adapter

- Clean and Inspect for Reuse

- Finishing Steps

- Install

- Preparatory Steps

- Remove

- Lubricating Oil Leaks

- Initial Check

- Lubricating Oil Lines

- Inspect for Reuse

- Install

- Remove

- Lubricating Oil Pan

- Clean and Inspect for Reuse

- Finishing Steps

- Install

- Preparatory Steps

- Remove

- Lubricating Oil Pressure Regulator (Main Rifle)

- Clean

- Finishing Steps

- Inspect for Reuse

- Install

- Preparatory Steps

- Remove

- Lubricating Oil Pressure Sensor, OEM

- Install

- Remove

- Lubricating Oil Pump

- Clean and Inspect for Reuse

- Finishing Steps

- Initial Check

- Install

- Measure

- Preparatory Steps

- Remove

- Lubricating Oil Suction Tube (Block-Mounted)

- Clean and Inspect for Reuse

- Finishing Steps

- Install

- Preparatory Steps

- Remove

- Lubricating Oil System

- Drain

- Fill

- Measure

- Service Tools

- Lubricating Oil System

- Belt Guard

- Inspect for Reuse

- Install

- Remove

- Coolant Heater

- Clean and Inspect for Reuse

- Finishing Steps

- Install

- Flange Mounted

- Threaded

- Preparatory Steps

- Remove

- Coolant Return Junction Block

- Clean and Inspect for Reuse

- Finishing Steps

- Install

- Preparatory Steps

- Remove

- Coolant Thermostat

- Clean and Inspect for Reuse

- Finishing Steps

- General Information

- Install

- Leak Test

- Preparatory Steps

- Remove

- Coolant Thermostat Housing

- Assemble

- Clean and Inspect for Reuse

- Disassemble

- Finishing Steps

- General Information

- Install

- Leak Test

- Preparatory Steps

- Remove

- Coolant Thermostat Housing Support

- Clean and Inspect for Reuse

- Finishing Steps

- General Information

- Install

- Preparatory Steps

- Remove

- Coolant Vent Lines

- Finishing Steps

- General Information

- Install

- Preparatory Steps

- Remove

- Cooling Fan Belt Tensioner

- Finishing Steps

- Inspect for Reuse

- Install

- Preparatory Steps

- Remove

- Cooling System

- Coolant Replacer Method

- Drain

- Fill

- Flush

- General Information

- Cooling System Diagnostics

- Analyzing the Data

- General Information

- Initial Check

- Pressure Test

- Test

- Worksheet

- Drive Belt, Cooling Fan

- Inspect for Reuse

- Install

- Remove

- Drive Belt, Sea Water Pump

- Finishing Steps

- Inspect for Reuse

- Install

- Preparatory Steps

- Remove

- Expansion Tank

- Finishing Steps

- General Information

- Initial Check

- Inspect for Reuse

- Install

- Preparatory Steps

- Remove

- Fan Clutch, On-Off

- General Information

- Fan Hub, Belt Driven

- Clean and Inspect for Reuse

- Finishing Steps

- Install

- Preparatory Steps

- Remove

- Fan Shroud Assembly

- Inspect for Reuse

- Install

- Remove

- Fan Spacer and Pulley

- Clean and Inspect for Reuse

- Finishing Steps

- Install

- Preparatory Steps

- Remove

- Fan, Cooling

- Inspect for Reuse

- Heat Exchanger

- Clean and Inspect for Reuse

- Finishing Steps

- Install

- Preparatory Steps

- Remove

- Keel Cooler

- General Information

- Pressure Differential Test

- Temperature Differential Test

- Marine Gear Oil Cooler

- Assemble

- Disassemble

- Finishing Steps

- Flush

- Inspect for Reuse

- Install

- Preparatory Steps

- Remove

- Radiator

- General Information

- Initial Check

- Radiator Hoses

- Inspect for Reuse

- Radiator Pressure Cap

- General Information

- Inspect for Reuse

- Radiator Shutter Assembly

- General Information

- Sea Water Pump

- Finishing Steps

- Initial Check

- Inspect for Reuse

- Install

- Preparatory Steps

- Remove

- Repair

- Sea Water Pump Pulley

- Clean and Inspect for Reuse

- Finishing Steps

- Install

- Preparatory Steps

- Remove

- Sea Water Pump Support

- Clean and Inspect for Reuse

- Finishing Steps

- Install

- Preparatory Steps

- Remove

- Sea Water Strainer

- Assemble

- Marine Applications

- Clean

- Marine Applications

- Disassemble

- Marine Applications

- General Information

- Marine Applications

- Prime

- Marine Applications

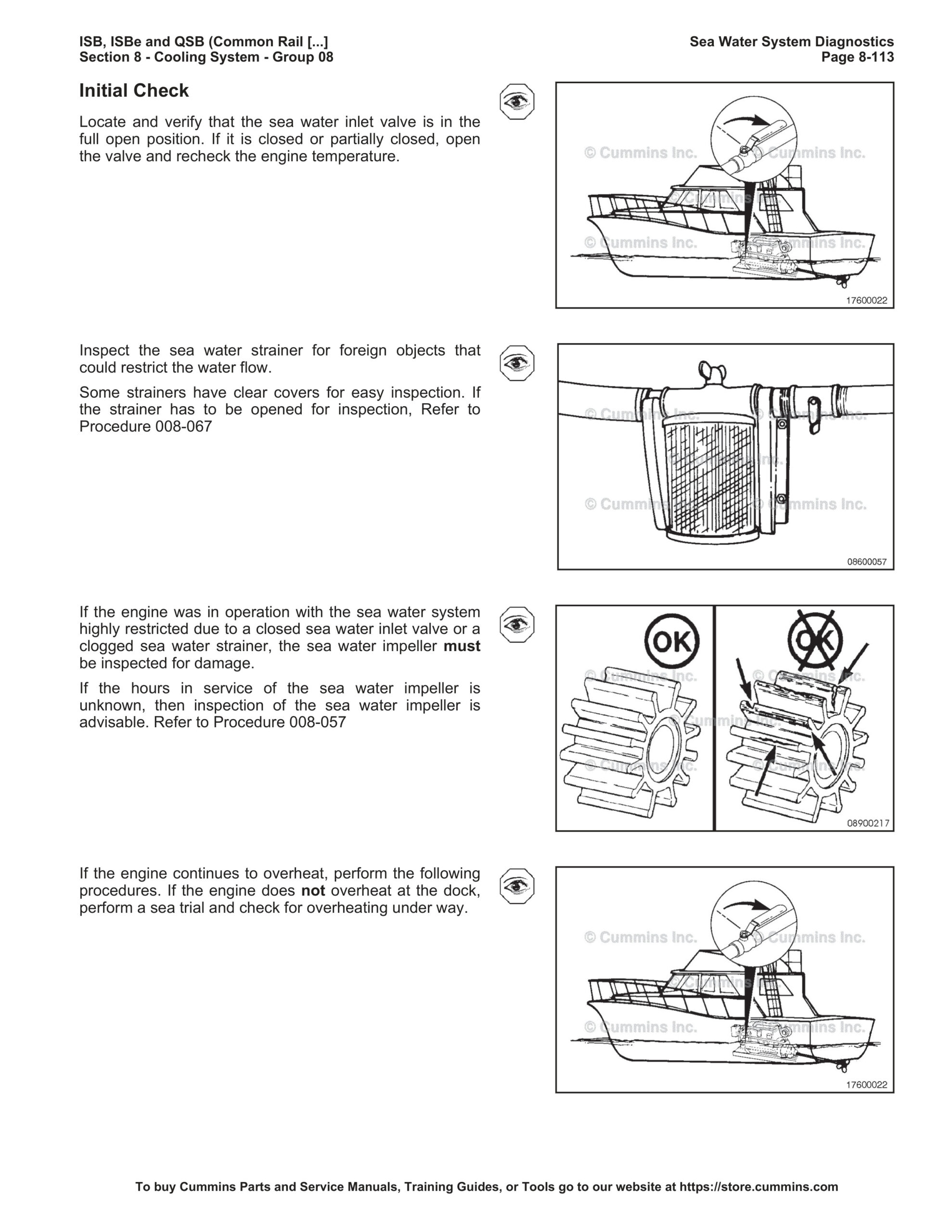

- Sea Water System Diagnostics

- General Information

- Initial Check

- Pressure Differential Test

- Pressure Test

- Temperature Differential Test

- Test

- Service Tools

- Cooling System

- Water Inlet Connection

- Clean and Inspect for Reuse

- Finishing Steps

- Initial Check

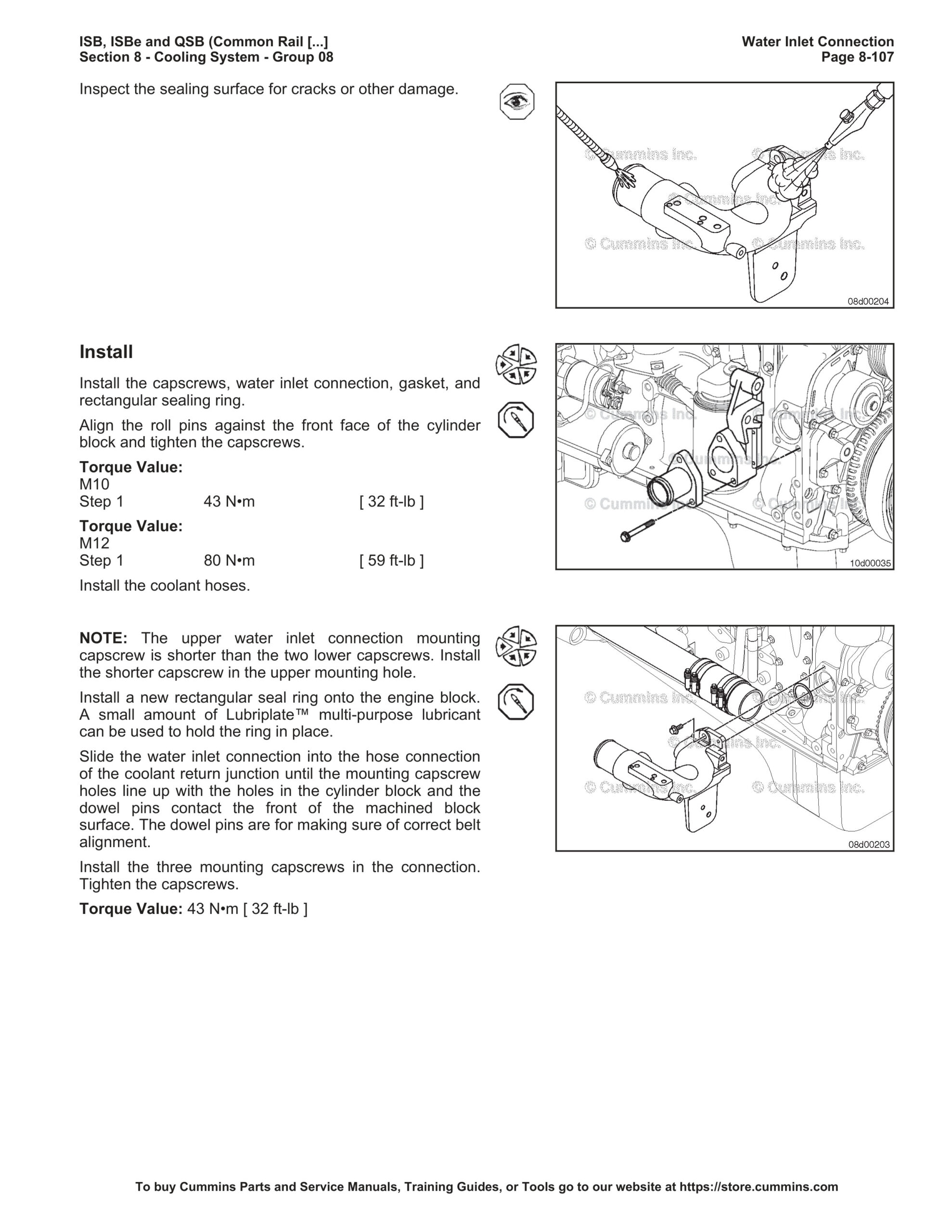

- Install

- Preparatory Steps

- Remove

- Water Pump

- Clean and Inspect for Reuse

- Finishing Steps

- General Information

- Initial Check

- Install

- Measure

- Preparatory Steps

- Remove

- Zinc Anode

- Install

- Remove

- Accessory Drive

- Assemble

- Clean and Inspect for Reuse

- Disassemble

- Finishing Steps

- Initial Check

- Install

- Measure

- Preparatory Steps

- Remove

- Belt Tensioner, Refrigerant Compressor, Automatic

- Finishing Steps

- Initial Check

- Install

- Install

- Preparatory Steps

- Remove

- Drive Belt, Refrigerant Compressor

- Finishing Steps

- Inspect for Reuse

- Install

- Preparatory Steps

- Remove

- Hydraulic Pump Drive

- Clean and Inspect for Reuse

- Finishing Steps

- Install

- Preparatory Steps

- Remove

- Idler Pulley Mounting Bracket

- Clean and Inspect for Reuse

- Finishing Steps

- Install

- Preparatory Steps

- Remove

- Idler Pulley Sea Water Pump

- Clean and Inspect for Reuse

- Finishing Steps

- Install

- Preparatory Steps

- Remove

- Refrigerant Compressor

- Finishing Steps

- Inspect for Reuse

- Install

- Preparatory Steps

- Remove

- Refrigerant Compressor Mounting Bracket

- Clean and Inspect for Reuse

- Finishing Steps

- Install

- Preparatory Steps

- Remove

- REPTO

- Clean and Inspect for Reuse

- Disassemble

- Exploded View

- Finishing Steps

- Install

- Preparatory Steps

- Remove

- Preparatory Steps

- Aftercooler Assembly

- Assemble

- Clean and Inspect for Reuse

- Disassemble

- Finishing Steps

- Initial Check

- Install

- Preparatory Steps

- Pressure Test

- Remove

- Air Cleaner Assembly (Engine Mounted)

- Clean

- General Information

- Initial Check

- Install

- Remove

- Air Crossover

- Clean and Inspect for Reuse

- Finishing Steps

- General Information

- Install

- Remove

- Air Inlet Connection

- Clean and Inspect for Reuse

- Finishing Steps

- General Information

- Install

- Remove

- Air Intake Connection

- Clean and Inspect for Reuse

- Finishing Steps

- Install

- Preparatory Steps

- Remove

- Air Intake Connection Adapter

- Clean and Inspect for Reuse

- Finishing Steps

- General Information

- Install

- Preparatory Steps

- Remove

- Air Intake Manifold

- Clean and Inspect for Reuse

- Finishing Steps

- General Information

- Install

- Preparatory Steps

- Remove

- Air Intake Manifold Cover

- Clean and Inspect for Reuse

- Finishing Steps

- Install

- Preparatory Steps

- Remove

- Air Intake Restriction

- Measure

- Air Leaks, Air Intake and Exhaust Systems

- Initial Check

- Charge-Air Cooler (CAC)

- Clean

- Finishing Steps

- Initial Check

- Install

- Leak Test

- Preparatory Steps

- Pressure Test

- Remove

- Temperature Differential Test

- Charge-Air Piping

- Maintenance Check

- Cold Starting Aid

- Clean and Inspect for Reuse

- Finishing Steps

- General Information

- Install

- Preparatory Steps

- Remove

- Test

- Boost Pressure

- Measure

- Service Tools

- Air Intake System

- Turbocharger

- Clean and Inspect for Reuse

- Finishing Steps

- Initial Check

- Install

- Leak Test

- Preparatory Steps

- Prime

- Remove

- Turbocharger Compressor Outlet Connection

- Clean and Inspect for Reuse

- Finishing Steps

- General Information

- Install

- Preparatory Steps

- Remove

- Turbocharger Coolant Hoses

- Finishing Steps

- Inspect

- Install

- Preparatory Steps

- Remove

- Turbocharger Oil Drain Line

- Clean and Inspect for Reuse

- Initial Check

- Install

- Remove

- Turbocharger Oil Supply Line

- Initial Check

- Inspect for Reuse

- Install

- Remove

- Turbocharger Wastegate Actuator

- Initial Check

- Install

- Leak Test

- Remove

- Turbocharger Wastegate Valve Body

- Maintenance Check

- Variable Geometry Turbo Actuator

- Finishing Steps

- Install

- Preparatory Steps

- Remove

- Aftertreatment Diesel Exhaust Fluid Dosing Unit

- Finishing Steps

- General Information

- Initial Check

- Install

- Preparatory Steps

- Remove

- Test

- Aftertreatment Diesel Exhaust Fluid Dosing Unit Air Side Flushing

- Finishing Steps

- Flush

- General Information

- Initial Check

- Preparatory Steps

- Test

- Aftertreatment Diesel Exhaust Fluid Dosing Unit Filter

- Finishing Steps

- General Information

- Initial Check

- Inspect for Reuse

- Install

- Preparatory Steps

- Remove

- Aftertreatment Diesel Exhaust Fluid Line Restriction Test

- Finishing Steps

- General Information

- Initial Check

- Preparatory Steps

- Remove

- Test

- Aftertreatment Diesel Exhaust Fluid Tank Filter

- Finishing Steps

- General Information

- Inspect for Reuse

- Install

- Preparatory Steps

- Remove

- Aftertreatment Nozzle

- Clean and Inspect for Reuse

- Finishing Steps

- General Information

- Initial Check

- Install

- Preparatory Steps

- Remove

- Aftertreatment Selective Catalytic Reduction (SCR) Catalyst

- Clean and Inspect for Reuse

- Finishing Steps

- General Information

- Install

- Preparatory Steps

- Remove

- EGR Connection Tubes

- Inspect for Reuse

- Install

- Remove

- Exhaust Gas Recirculation Cooler

- Clean and Inspect for Reuse

- Finishing Steps

- Install

- Preparatory Steps

- Remove

- Test

- EGR Cooler Connection

- Inspect for Reuse

- Install

- Remove

- EGR Cooler Coolant Lines

- Clean and Inspect

- Finishing Steps

- Install

- Preparatory Steps

- Remove

- EGR Mixer

- Clean and Inspect

- Finishing Steps

- Install

- Preparatory Steps

- Remove

- EGR Valve

- Clean and Inspect for Reuse

- Finishing Steps

- Install

- Preparatory Steps

- Remove

- EGR Valve Coolant Lines

- Finishing Steps

- Inspect for Reuse

- Install

- Preparatory Steps

- Remove

- Exhaust Pressure Sensor Tube

- Clean and Inspect

- Install

- Remove

- Exhaust Manifold, Dry

- Clean and Inspect for Reuse

- Finishing Steps

- Install

- Preparatory Steps

- Remove

- Exhaust Manifold, Wet

- Clean and Inspect for Reuse

- Finishing Steps

- Install

- Preparatory Steps

- Remove

- Exhaust Outlet Connection

- Clean and Inspect for Reuse

- Finishing Steps

- General Information

- Install

- Preparatory Steps

- Remove

- Exhaust Restriction

- Measure

- Service Tools

- Exhaust System

- Air Compressor

- Assemble

- Clean and Inspect for Reuse

- Finishing Steps

- Install

- Preparatory Steps

- Pressure Test

- Remove

- Time

- Air Compressor (Oil Carryover)

- Inspect for Reuse

- Air Compressor Carbon Buildup

- Clean

- Initial Check

- Preparatory Steps

- Air Compressor Coolant Lines

- Initial Check

- Inspect for Reuse

- Install

- Preparatory Steps

- Remove

- Air Compressor Cylinder Head, Single Cylinder

- Assemble

- Clean and Inspect for Reuse

- Disassemble

- Finishing Steps

- Initial Check

- Install

- Preparatory Steps

- Remove

- Air Compressor Cylinder Head, Two Cylinder

- Clean and Inspect for Reuse

- Finishing Steps

- Install

- Preparatory

- Remove

- Air Compressor Oil Drain Line

- Initial Check

- Inspect for Reuse

- Install

- Remove

- Air Compressor Rear Bearing Housing, Two Cylinder

- Clean and Inspect for Reuse

- Finishing Steps

- General Information

- Install

- Preparatory Steps

- Remove

- Air Compressor Unloader and Valve Assembly

- Initial Check

- Air Governor (Air Compressor Pumps Continuously)

- Initial Check

- Air Governor (Air Compressor Will Not Pump)

- Inspect for Reuse

- Air Leaks, Compressed Air System

- Initial Check

- Service Tools

- Compressed Air System

- Alternator

- Finishing Steps

- General Information

- Initial Check

- Install

- Preparatory Steps

- Remove

- Test

- Alternator Bracket

- Clean and Inspect for Reuse

- Finishing Steps

- Automotive and Industrial

- Marine Applications

- Initial Check

- Install

- Spool Mount

- Pad Mount

- Marine Applications

- Preparatory Steps

- Automotive and Industrial

- Marine Applications

- Remove

- Spool Mount

- Pad Mount

- Marine Applications

- Batteries

- Initial Check

- Battery Cables and Connections

- Initial Check

- Charging System Indicator

- Initial Check

- ECM Unswitched Power Terminal Blocks

- Finishing Steps

- General Information

- Initial Check

- Install

- Preparatory Steps

- Remove

- Key Switch

- Voltage Check

- Service Tools

- Electrical Equipment

- Starter Magnetic Switch

- Initial Check

- Resistance Check

- Voltage Check

- Starter Solenoid

- Initial Check

- Voltage Check

- Starting Motor

- Clean and Inspect for Reuse

- Finishing Steps

- Install

- Measure

- Preparatory Steps

- Remove

- Rotation Check

- Aftertreatment Testing

- Regeneration

- Crankcase Blowby, Measure

- General Information

- Initial Check

- Measure

- Engine Run-in (Chassis Dynamometer)

- Test

- Engine Run-in (Engine Dynamometer)

- Run-In Instructions

- Engine Run-in (Without Dynamometer)

- Test

- Engine Testing (Chassis Dynamometer)

- Setup

- Test

- Engine Testing (Engine Dynamometer)

- Setup

- Engine Testing (In Chassis)

- Automated Cylinder Performance Test

- Cylinder Cutout Test

- Setup

- Service Tools

- Engine Testing

- Engine Drive Shaft

- Adjust

- Finishing Steps

- General Information

- Install

- Measure

- Preparatory Steps

- Remove

- Setup

- Engine Lifting Brackets

- Clean and Inspect for Reuse

- Finishing Steps

- Install

- Preparatory Steps

- Remove

- Engine Mounts

- General Information

- Inspect for Reuse

- Install

- Remove

- Engine Support Bracket, Front

- Clean and Inspect for Reuse

- General Information

- Initial Check

- Install

- Remove

- Engine Support Bracket, Rear

- Clean and Inspect for Reuse

- General Information

- Initial Check

- Install

- Remove

- Flexplate

- Finishing Steps

- Initial Check

- Inspect for Reuse

- Install

- Preparatory Steps

- Remove

- Flywheel

- Assemble

- Clean and Inspect for Reuse

- Disassemble

- Finishing Steps

- Initial Check

- Install

- Measure

- Preparatory Steps

- Remove

- Flywheel Housing

- Assemble

- Clean and Inspect for Reuse

- Disassemble

- Finishing Steps

- Install

- Measure

- Preparatory Steps

- Remove

- Flywheel Ring Gear

- Assemble

- Disassemble

- General Information

- Marine Vibration Isolator

- Finishing Steps

- General Information

- Initial Check

- Inspect for Reuse

- Install

- Preparatory Steps

- Remove

- Propeller Shaft

- General Information

- Out of Water

- Alignment

- Preparatory Steps

- Specifications

- Service Tools

- Mounting Adaptations

- Cup Plug

- Clean and Inspect for Reuse

- Install

- Remove

- Pipe Plug

- Clean

- Inspect for Reuse

- Install

- Remove

- Service Tools

- Miscellaneous

- Straight Thread Plug

- Clean and Inspect for Reuse

- General Information

- Install

- Remove

- Engine Exhaust Brake

- General Information

- Install

- Remove

- Additional Service Literature

- General Information

- Cummins Customized Parts Catalog

- General Information

- Ordering the Customized Parts Catalog

- Service Literature Ordering Location

- Contact Information

- Air Intake System

- Specifications

- Air Intake System - Group 10 - Specifications

- Air Intake Restriction

- Turbocharger

- Air Intake System - Group 10 - Torque Values

- Aftercooler Assembly

- Air Crossover

- Air Intake Connection

- Air Intake Connection Adapter

- Air Intake Manifold

- Air Intake Manifold Cover

- Air Leaks, Air Intake and Exhaust Systems

- Cold Starting Aid

- Turbocharger

- Turbocharger Compressor Outlet Connection

- Turbocharger Coolant Hoses

- Turbocharger Oil Drain Line

- Turbocharger Oil Supply Line

- Turbocharger Wastegate Actuator

- Variable Geometry Turbo Actuator

- Cam Followers/Tappets - Group 04 - Specifications

- Tappet

- Capscrew Markings and Torque Values

- Capscrew Markings and Torque Values - Metric

- Capscrew Markings and Torque Values - US Customary

- General Information

- Compressed Air System - Group 12 - Torque Values

- Air Compressor

- Air Compressor Cylinder Head, Single Cylinder

- Air Compressor Cylinder Head, Two Cylinder

- Air Compressor Rear Bearing Housing, Two Cylinder

- Air Compressor

- Cooling System

- Specifications

- Cooling System - Group 08 - Specifications

- Coolant Thermostat

- Cooling System

- Fan Hub, Belt Driven

- Water Pump

- Zinc Anode

- Cooling System - Group 08 - Torque Values V-64

- Belt GuardV-64

- Coolant HeaterV-64

- Coolant Return Junction BlockV-68

- Coolant ThermostatV-64

- Coolant Thermostat HousingV-64

- Coolant Thermostat Housing SupportV-65

- Cooling Fan Belt TensionerV-68

- Drive Belt, Sea Water Pump V-69

- Expansion TankV-66

- Fan Hub, Belt DrivenV-65

- Fan Spacer and PulleyV-65

- Heat ExchangerV-66

- Marine Gear Oil Cooler V-65

- Sea Water PumpV-67

- Sea Water Pump PulleyV-69

- Sea Water Pump Support V-67

- Water Inlet Connection

- Zinc Anode

- Cummins®/Fleetguard® Filter Specifications

- General Information

- Cylinder Block - Group 01 - Specifications

- Bearings, Main

- Camshaft

- Camshaft Bushings

- Camshaft Gear (Camshaft Installed)

- Camshaft Gear (Camshaft Removed)

- Connecting Rod

- Crankshaft

- Crankshaft Gear, Front (Crankshaft Removed)

- Crankshaft Speed Indicator Ring

- Cylinder Block

- Piston

- Piston and Connecting Rod Assembly

- Piston Rings

- Cylinder Block - Group 01 - Torque Values

- Balancer

- Bearings, Connecting Rod

- Bearings, Main

- Block Stiffener Plate

- Camshaft

- Camshaft Gear (Camshaft Installed)

- Connecting Rod

- Crankshaft

- Crankshaft Seal, Front

- Crankshaft Seal, Rear

- Crankshaft Speed Indicator Ring

- Crankshaft Wear Sleeve, Front

- Crankshaft Wear Sleeve, Rear

- ECM Mounting Plate

- Gear Cover, Front

- Gear Housing, Front

- Gear Housing, Rear

- Piston and Connecting Rod Assembly

- Piston Cooling Nozzle

- Vibration Damper, Rubber

- Vibration Damper, Viscous

- Cylinder Head - Group 02 - Specifications

- Cylinder Head

- Cylinder Head - Group 02 - Torque Values

- Cylinder Head

- Mounting Bracket, Lubricating Oil and Fuel Filter

- Valve Guide Seal, Cylinder Head

- Drive Belt Tension

- Tension Chart

- Drive Units - Group 09 - Specifications

- Accessory Drive

- Drive Units - Group 09 - Torque Values

- Accessory Drive

- Belt Tensioner, Refrigerant Compressor, Automatic

- Hydraulic Pump Drive

- Idler Pulley Mounting Bracket

- Idler Pulley Sea Water Pump

- Refrigerant Compressor Mounting Bracket

- REPTO

- Electrical Equipment - Group 13 - Specifications

- Starting Motor

- Electrical Equipment - Group 13 - Torque Values

- Alternator

- Alternator Bracket

- ECM Unswitched Power Terminal Blocks

- Starting Motor

- Electrical System

- Specifications

- Engine Assembly - Group 00 - Specifications

- Crankshaft

- Lubricating Oil Pump

- Piston and Connecting Rod Assembly

- Engine Assembly - Group 00 - Torque Values

- Accessory Drive

- Air Compressor

- Air Intake Connection

- Air Intake Connection Adapter

- Air Intake Manifold

- Alternator

- Alternator Bracket

- Belt Guard

- Block Stiffener Plate

- Camshaft

- Camshaft Gear (Camshaft Installed)

- Coolant Thermostat Housing

- Coolant Thermostat Housing Support

- Crankcase Breather (External)

- Crankcase Breather (Internal)

- Crankcase Breather Tube

- Crankshaft

- Crankshaft Seal, Front

- Crankshaft Speed Indicator Ring

- Crankshaft Wear Sleeve, Rear

- ECM Cooling Plate, Fuel Cooled

- ECM Mounting Plate

- Engine Support Bracket, Front

- Engine Support Bracket, Rear

- Exhaust Manifold, Dry

- Fan Hub, Belt Driven

- Fan Spacer and Pulley

- Flexplate

- Flywheel

- Flywheel Housing

- Fuel Connector (Head Mounted)

- Fuel Drain Lines

- Fuel Filter (Spin-On Type)

- Fuel Filter Head

- Fuel Lift Pump

- Fuel Pump

- Fuel Rail

- Fuel Supply Lines (High Pressure)

- Gear Cover, Front

- Gear Housing, Front

- Gear Housing, Rear

- Injector

- Injector Supply Lines (High Pressure)

- Lubricating Oil Cooler

- Lubricating Oil Lines

- Lubricating Oil Pan

- Lubricating Oil Pump

- Lubricating Oil Suction Tube (Block-Mounted)

- Piston and Connecting Rod Assembly

- Piston Cooling Nozzle

- Rocker Lever

- Rocker Lever Cover

- Rocker Lever Housing

- Sea Water Pump Pulley

- Starting Motor

- Turbocharger

- Turbocharger Oil Drain Line

- Turbocharger Oil Supply Line

- Vibration Damper, Rubber

- Vibration Damper, Viscous

- Water Inlet Connection

- Engine Disassembly - Group 00 - Torque Values

- Crankshaft Seal, Front

- Crankshaft Seal, Rear

- Engine Testing - Group 14 - Specifications

- Engine Run-in (Engine Dynamometer)

- Engine Testing (Engine Dynamometer)

- Engine Testing - Group 14 - Torque Values

- Engine Testing (Engine Dynamometer)

- Exhaust System

- Specifications

- Exhaust System - Group 11 - Specifications

- Exhaust Manifold, Dry

- Exhaust Restriction

- Exhaust System - Group 11 - Torque Values

- EGR Connection Tubes

- EGR Cooler Connection

- Aftertreatment Diesel Exhaust Fluid Dosing Unit Filter

- Aftertreatment Nozzle

- EGR Cooler Coolant Lines

- EGR Valve

- EGR Valve Coolant Lines

- Exhaust Gas Recirculation Cooler

- Exhaust Manifold, Dry

- Exhaust Manifold, Wet

- Exhaust Outlet Connection

- Exhaust Pressure Sensor Tube

- Fraction, Decimal, Millimeter Conversions

- Conversion Chart

- Fuel System

- Specifications

- Fuel System - Group 05 - Torque Values

- EFC Actuator Valve

- Engine Fuel Heater, Electric

- Fuel Lift Pump

- Fuel Pump

- General Engine

- Specifications

- Injectors and Fuel Lines - Group 06 - Specifications

- Fuel Drain Line Restriction

- Fuel Filter (Spin-On Type)

- Fuel Inlet Restriction

- Injectors and Fuel Lines - Group 06 - Torque Values

- ECM Cooling Plate, Fuel Cooled

- Fuel Connector (Head Mounted)

- Fuel Cooler

- Fuel Drain Lines

- Fuel Filter (Spin-On Type)

- Fuel Filter Head

- Fuel Filter Head Bracket

- Fuel Manifold (Combined)

- Fuel Pressure Relief Valve

- Fuel Rail

- Fuel Return Overflow Valve

- Fuel Supply Lines

- Injector

- Injector Supply Lines (High Pressure)

- Lubricating Oil System

- Specifications

- Lubricating Oil System - Group 07 - Specifications

- Lubricating Oil Cooler

- Lubricating Oil Pressure Regulator (Main Rifle)

- Lubricating Oil Pump

- Lubricating Oil System

- Lubricating Oil System - Group 07 - Torque Values

- Engine Oil Heater

- Lubricating Oil Cooler

- Lubricating Oil Filter Head (Remote Mounted)

- Lubricating Oil Filter Head Adapter

- Lubricating Oil Lines

- Lubricating Oil Pan

- Lubricating Oil Pressure Regulator (Main Rifle)

- Lubricating Oil Pressure Sensor, OEM

- Lubricating Oil Pump

- Lubricating Oil Suction Tube (Block-Mounted)

- Miscellaneous - Group 17 - Torque Values

- Mounting Adaptations - Group 16 - Specifications

- Flywheel

- Mounting Adaptations - Group 16 - Torque Values

- Engine Drive Shaft

- Engine Lifting Brackets

- Engine Support Bracket, Front

- Engine Support Bracket, Rear

- Flexplate

- Flywheel

- Flywheel Housing

- Newton-Meter to Foot-Pound Conversions

- Conversion Chart

- Pipe Plug Torque Values

- Torque Table

- Rocker Levers - Group 03 - Specifications

- Overhead Set

- Rocker Lever

- Rocker Levers - Group 03 - Torque Values

- Crankcase Breather (External)

- Crankcase Breather (Internal)

- Crankcase Breather Tube

- Overhead Set

- Rocker Lever

- Rocker Lever Cover

- Rocker Lever Housing

- Tap-Drill Chart - US Customary and Metric

- General Information

- Vehicle Braking - Group 20 - Torque Values

- Engine Exhaust Brake

- Weights and Measures - Conversion Factors

- Conversion Chart

Abrites AVDI J2534

Abrites AVDI J2534 Actia Multi-Diag

Actia Multi-Diag Autoland iSCAN

Autoland iSCAN BMW ENET

BMW ENET Bosch Mastertech II J2534

Bosch Mastertech II J2534 Bosch MTS 6531

Bosch MTS 6531 CAN CLIP RLT2002

CAN CLIP RLT2002 CarDAQ-Plus 3

CarDAQ-Plus 3 Cummins INLINE Datalink

Cummins INLINE Datalink Dearborn Protocol Adapter (DPA) 5

Dearborn Protocol Adapter (DPA) 5 Delphi/Autocom DS150E

Delphi/Autocom DS150E Volvo VIDA DiCE

Volvo VIDA DiCE Derelek USB DIAG 3

Derelek USB DIAG 3 Electronic Data Link (EDL) 2

Electronic Data Link (EDL) 2 Electronic Data Link (EDL) 3

Electronic Data Link (EDL) 3 GM MDI 1

GM MDI 1 GM MDI 2

GM MDI 2 HEX-V2 VCDS VAG-COM

HEX-V2 VCDS VAG-COM Isuzu IDSS IDS MX1

Isuzu IDSS IDS MX1 Isuzu IDSS IDS MX2

Isuzu IDSS IDS MX2 Iveco Eltrac E.A.SY. ECI

Iveco Eltrac E.A.SY. ECI MaxiFlash Elite J2534

MaxiFlash Elite J2534 Mongoose J2534

Mongoose J2534 Nexiq USB-Link 1

Nexiq USB-Link 1 Nexiq USB-Link 2

Nexiq USB-Link 2 Nexiq USB-Link 3

Nexiq USB-Link 3 Noregon DLA+ 2.0

Noregon DLA+ 2.0 Porsche PIWIS TESTER 3 (PT3G)

Porsche PIWIS TESTER 3 (PT3G) PSA LEXIA 3

PSA LEXIA 3 SAE J2434

SAE J2434 Scania VCI 3

Scania VCI 3 Scanmatik 2 PRO

Scanmatik 2 PRO SD Connect Multiplexer

SD Connect Multiplexer Tactrix OpenPort 2.0

Tactrix OpenPort 2.0 Toyota TIS Mini VCI

Toyota TIS Mini VCI VAG ODIS VAS5054 Clone

VAG ODIS VAS5054 Clone VAG ODIS VAS6154 Clone

VAG ODIS VAS6154 Clone Volvo VOCOM 1

Volvo VOCOM 1 Volvo VOCOM 2

Volvo VOCOM 2

Franki –

Responsive honest company. Product worked.

j*** –

Excellent item and swift despatch