The FPT F5H Tier 4 engine is a 3.4 L common-rail diesel designed for Tier 4A emission compliance using CEGR (Cooled Exhaust Gas Recirculation) and a DPF (Diesel Particulate Filter) system.

This manual covers detailed service procedures, regeneration cycles, system layout, and component logic for machines such as the CASE 750M Dozer, SR Series Skid Steers, and N Series TLBs.

Key subsystems include:

Bosch EDC17C49 ECU with DPF management

EGR cooling and boost pressure modulator control

CJ-4 low-ash lubricants and 15 ppm sulfur diesel requirement

Automatic, manual, and service DPF regeneration modes

Temperature, pressure, and lambda sensor monitoring for NOx and PM control

Coverage

Introduction

Overview of Tier 4 emission standards

CNH compliance timeline and requirements

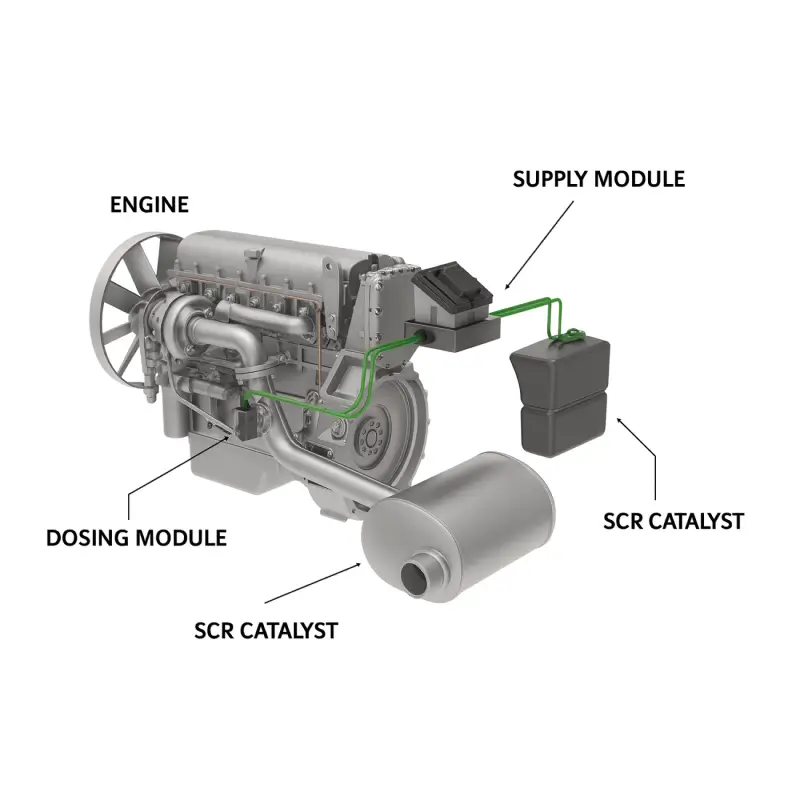

SCR vs CEGR/DPF comparison

Lubricants and Fuel Requirements

CJ-4 oil classification and ash limits

CNH Tutela Unitek specifications

Low-sulfur diesel (15 ppm) usage

Temperature guidelines for CI-4 and CJ-4 oils

Engine Overview

3.4 L Common Rail architecture

DPF and EGR system integration

Component layout for 750M Dozer and SR Loaders

Fuel and Injection System

Bosch CP4.1 pump operation

Injector coding and EST configuration

Glow plug controller and harness assembly

Electronic Control Unit

Bosch EDC17C49 functions

Control logic for EGR and DPF cycles

Sensor inputs and output processing

DPF and DOC System

Construction and flow pattern

Differential pressure and temperature sensors

Regeneration cycle stages and timing

Passive, automatic, manual, and service regeneration

Emission Control Components

Intake Air Valve mechanism

Boost Pressure Modulator and accumulator

Lambda (HEGO) Sensor function

Cooled EGR system operation

Diagnostics and Service

DPF soot load monitoring logic

EST reset procedures for relief valves and injectors

DPF service reset and configuration steps

Dosing and temperature regulation curves

Mechanical Updates

Hydraulic lifters (non-adjustable)

Crankcase vent filter angle and mounting

Front cover alignment tools (380100280/281)

Plastic thermostat housing and stretch-belt design

Delivery

The download link will be sent to your email instantly after payment.

Abrites AVDI J2534

Abrites AVDI J2534 Actia Multi-Diag

Actia Multi-Diag Autoland iSCAN

Autoland iSCAN Bobcat Diagnostic Kit

Bobcat Diagnostic Kit BMW ENET

BMW ENET Bosch Mastertech II J2534

Bosch Mastertech II J2534 Bosch MTS 6531

Bosch MTS 6531 CAN CLIP RLT2002

CAN CLIP RLT2002 CarDAQ-Plus 3

CarDAQ-Plus 3 Cummins INLINE Datalink

Cummins INLINE Datalink Dearborn Protocol Adapter (DPA) 5

Dearborn Protocol Adapter (DPA) 5 Delphi/Autocom DS150E

Delphi/Autocom DS150E DrewLinQ

DrewLinQ Volvo VIDA DiCE

Volvo VIDA DiCE Derelek USB DIAG 3

Derelek USB DIAG 3 Electronic Data Link (EDL) 2

Electronic Data Link (EDL) 2 Electronic Data Link (EDL) 3

Electronic Data Link (EDL) 3 GM MDI 1

GM MDI 1 GM MDI 2

GM MDI 2 HEX-V2 VCDS VAG-COM

HEX-V2 VCDS VAG-COM Isuzu IDSS IDS MX1

Isuzu IDSS IDS MX1 Isuzu IDSS IDS MX2

Isuzu IDSS IDS MX2 Iveco Eltrac E.A.SY. ECI

Iveco Eltrac E.A.SY. ECI MaxiFlash Elite J2534

MaxiFlash Elite J2534 MB Star C6

MB Star C6 Mongoose J2534

Mongoose J2534 Nexiq USB-Link 1

Nexiq USB-Link 1 Nexiq USB-Link 2

Nexiq USB-Link 2 Nexiq USB-Link 3

Nexiq USB-Link 3 Noregon DLA+ 2.0

Noregon DLA+ 2.0 Porsche PIWIS TESTER 3 (PT3G)

Porsche PIWIS TESTER 3 (PT3G) PSA LEXIA 3

PSA LEXIA 3 SAE J2434

SAE J2434 Scania VCI 3

Scania VCI 3 Scanmatik 2 PRO

Scanmatik 2 PRO SD Connect Multiplexer

SD Connect Multiplexer Tactrix OpenPort 2.0

Tactrix OpenPort 2.0 Toyota TIS Mini VCI

Toyota TIS Mini VCI VAG ODIS VAS5054 Clone

VAG ODIS VAS5054 Clone VAG ODIS VAS6154 Clone

VAG ODIS VAS6154 Clone Volvo VOCOM 1

Volvo VOCOM 1 Volvo VOCOM 2

Volvo VOCOM 2 Xentry VCI

Xentry VCI Yanmar Diagnostic Interface Box (IFBOX)

Yanmar Diagnostic Interface Box (IFBOX)

Reviews

Clear filtersThere are no reviews yet.