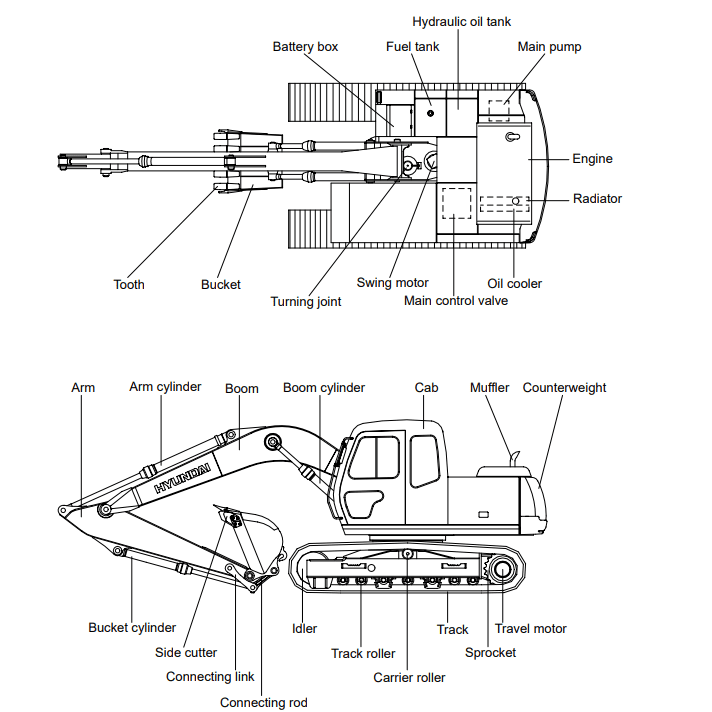

The Hyundai Crawler Excavator R130LC-3 Service & Repair Manual is an essential resource for maintaining and repairing your excavator. This comprehensive manual offers detailed instructions, troubleshooting tips, and expert advice to keep your machine operating efficiently. Designed for both professional technicians and operators, this guide ensures your excavator performs at its peak, reducing downtime and extending its lifespan.

Key Features:

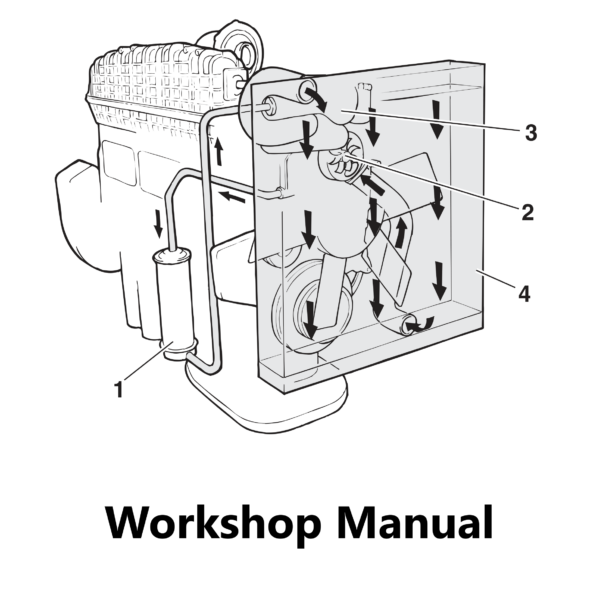

- Comprehensive Maintenance Procedures: Step-by-step guidance for routine maintenance, including lubrication, filter replacements, and system checks.

- Detailed Repair Instructions: Covers engine, hydraulic systems, electrical components, and structural repairs to ensure reliable operation.

- Troubleshooting Assistance: Expert tips and diagnostic procedures to identify and resolve common issues quickly and efficiently.

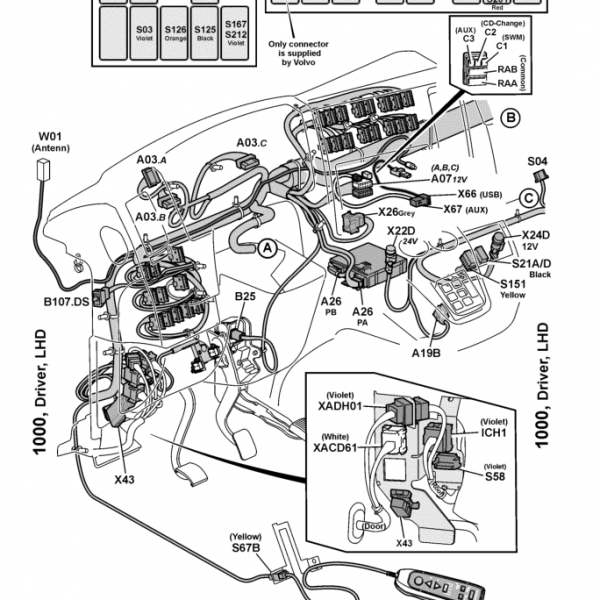

- High-Quality Diagrams: Clear illustrations and schematics provide a detailed understanding of the machine’s components and repair processes.

- OEM Standards Compliance: Ensures all servicing meets Hyundai’s original specifications for safety and performance.

Format: Interactive HTML

Delivery: The download link will be promptly delivered to your email upon completing the checkout process.

| Section | Group | Description |

|---|---|---|

| Foreword | ||

| Section 1: General | Group 1 | Safety Hints |

| Group 2 | Specifications | |

| Section 2: Structure and Function | Group 1 | Pump Device |

| Group 2 | Main Control Valve | |

| Group 3 | Swing Device | |

| Group 4 | Travel Device | |

| Group 5 | RCV Lever | |

| Group 6 | RCV Pedal | |

| Section 3: Hydraulic System | Group 1 | Hydraulic Circuit |

| Group 2 | Main Circuit | |

| Group 3 | Pilot Circuit | |

| Group 4 | Single Operation | |

| Group 5 | Combined Operation | |

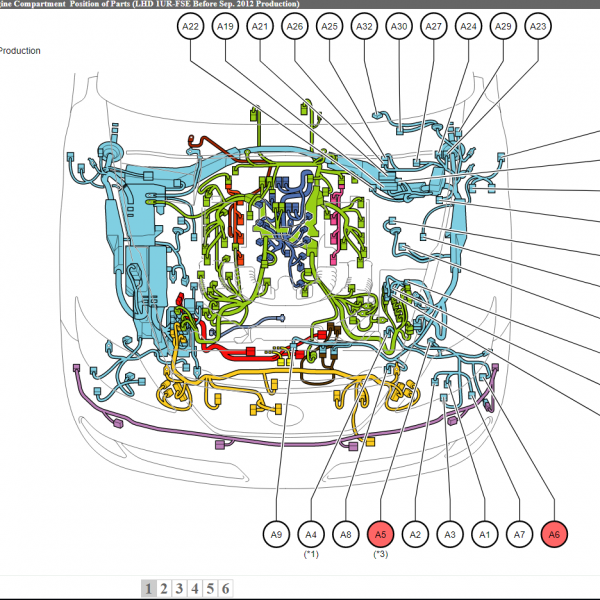

| Section 4: Electrical System | Group 1 | Component Location |

| Group 2 | Electrical Circuit | |

| Group 3 | Monitoring System | |

| Group 4 | Electrical Component Specification | |

| Group 5 | Connectors | |

| Section 5: Mechatronics System | Group 1 | Outline |

| Group 2 | Operation of CAPO System | |

| Group 3 | System Diagram | |

| Group 4 | Engine Control System | |

| Group 5 | EPPR Valve | |

| Group 6 | Prolix Switch | |

| Group 7 | Function and Electrical Circuit | |

| Section 6: Troubleshooting | Group 1 | Hydraulic and Mechanical System |

| Group 2 | Electrical System | |

| Group 3 | Mechatronics System | |

| Section 7: Maintenance Standard | Group 1 | Operational Performance Test |

| Group 2 | Major Components | |

| Group 3 | Track and Work Equipment | |

| Section 8: Disassembly and Assembly | Group 1 | Precaution |

| Group 2 | Tightening Torque | |

| Group 3 | Pump Device | |

| Group 4 | Main Control Valve | |

| Group 5 | Swing Device | |

| Group 6 | Travel Device | |

| Group 7 | RCV Lever | |

| Group 8 | Turning Joint | |

| Group 9 | Boom, Arm, and Bucket Cylinder | |

| Group 10 | Undercarriage | |

| Group 11 | Work Equipment | |

Abrites AVDI J2534

Abrites AVDI J2534 Actia Multi-Diag

Actia Multi-Diag Autoland iSCAN

Autoland iSCAN Bobcat Diagnostic Kit

Bobcat Diagnostic Kit BMW ENET

BMW ENET Bosch Mastertech II J2534

Bosch Mastertech II J2534 Bosch MTS 6531

Bosch MTS 6531 CAN CLIP RLT2002

CAN CLIP RLT2002 CarDAQ-Plus 3

CarDAQ-Plus 3 Cummins INLINE Datalink

Cummins INLINE Datalink Dearborn Protocol Adapter (DPA) 5

Dearborn Protocol Adapter (DPA) 5 Delphi/Autocom DS150E

Delphi/Autocom DS150E Volvo VIDA DiCE

Volvo VIDA DiCE Derelek USB DIAG 3

Derelek USB DIAG 3 Electronic Data Link (EDL) 2

Electronic Data Link (EDL) 2 Electronic Data Link (EDL) 3

Electronic Data Link (EDL) 3 GM MDI 1

GM MDI 1 GM MDI 2

GM MDI 2 HEX-V2 VCDS VAG-COM

HEX-V2 VCDS VAG-COM Isuzu IDSS IDS MX1

Isuzu IDSS IDS MX1 Isuzu IDSS IDS MX2

Isuzu IDSS IDS MX2 Iveco Eltrac E.A.SY. ECI

Iveco Eltrac E.A.SY. ECI MaxiFlash Elite J2534

MaxiFlash Elite J2534 Mongoose J2534

Mongoose J2534 Nexiq USB-Link 1

Nexiq USB-Link 1 Nexiq USB-Link 2

Nexiq USB-Link 2 Nexiq USB-Link 3

Nexiq USB-Link 3 Noregon DLA+ 2.0

Noregon DLA+ 2.0 Porsche PIWIS TESTER 3 (PT3G)

Porsche PIWIS TESTER 3 (PT3G) PSA LEXIA 3

PSA LEXIA 3 SAE J2434

SAE J2434 Scania VCI 3

Scania VCI 3 Scanmatik 2 PRO

Scanmatik 2 PRO SD Connect Multiplexer

SD Connect Multiplexer Tactrix OpenPort 2.0

Tactrix OpenPort 2.0 Toyota TIS Mini VCI

Toyota TIS Mini VCI VAG ODIS VAS5054 Clone

VAG ODIS VAS5054 Clone VAG ODIS VAS6154 Clone

VAG ODIS VAS6154 Clone Volvo VOCOM 1

Volvo VOCOM 1 Volvo VOCOM 2

Volvo VOCOM 2

Reviews

Clear filtersThere are no reviews yet.