VW 3-cylinder injection engine (1.0 l, natural gas, 4 V EA 211, turbocharger) OEM Workshop Manual with high-quality graphics and illustrations.

Format: PDF

Pages: 328

Delivery: The download link will be sent to your email instantly after checkout.

Covered VW Vehicles

- Polo 2018 ➤

Covered Engine IDs: DBYA

Repair Group:

- Technical data

- Removing and installing engine

- Crankshaft group

- Cylinder head, valve gear

- Lubrication

- Cooling

- Turbocharging/supercharging

- Mixture preparation – injection

- Exhaust system

- Ignition system

Contents:

- Technical data

- Safety information

- Safety measures when working on fuel supply

- Safety precautions when working on vehicles with a gas system

- Safety measures when working on vehicles with a start/stop system

- Safety precautions when using testers and measuring instruments during a road test

- Safety precautions when working on the cooling system

- Safety precautions when working on ignition system

- Identification

- Engine number/engine data

- Repair instructions

- Rules for cleanliness

- General information

- General repair instructions

- Foreign objects in engine

- Contact corrosion

- Routing and attachment of lines

- Fitting radiator and condensers

- Checking vacuum system

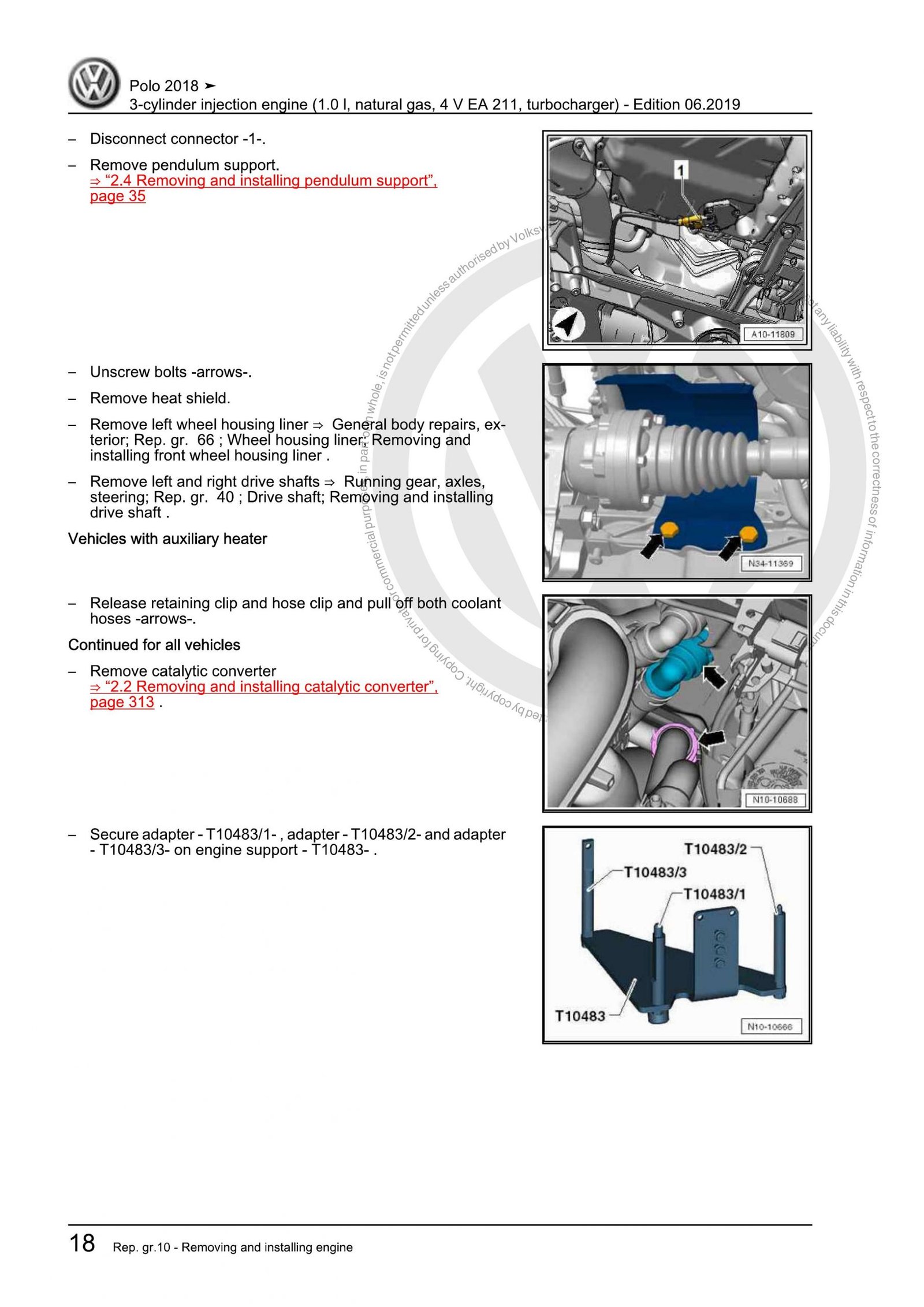

- Removing and installing engine

- Removing and installing engine

- Removing engine

- Separating engine and gearbox

- Securing engine on engine and gearbox support

- Installing engine

- Assembly mountings

- Assembly overview – assembly mountings

- Removing and installing engine mounting

- Removing and installing gearbox mounting

- Removing and installing pendulum support

- Checking adjustment of assembly mountings (engine and gearbox mountings)

- Adjusting assembly mountings

- Supporting engine in installation position

- Crankshaft group

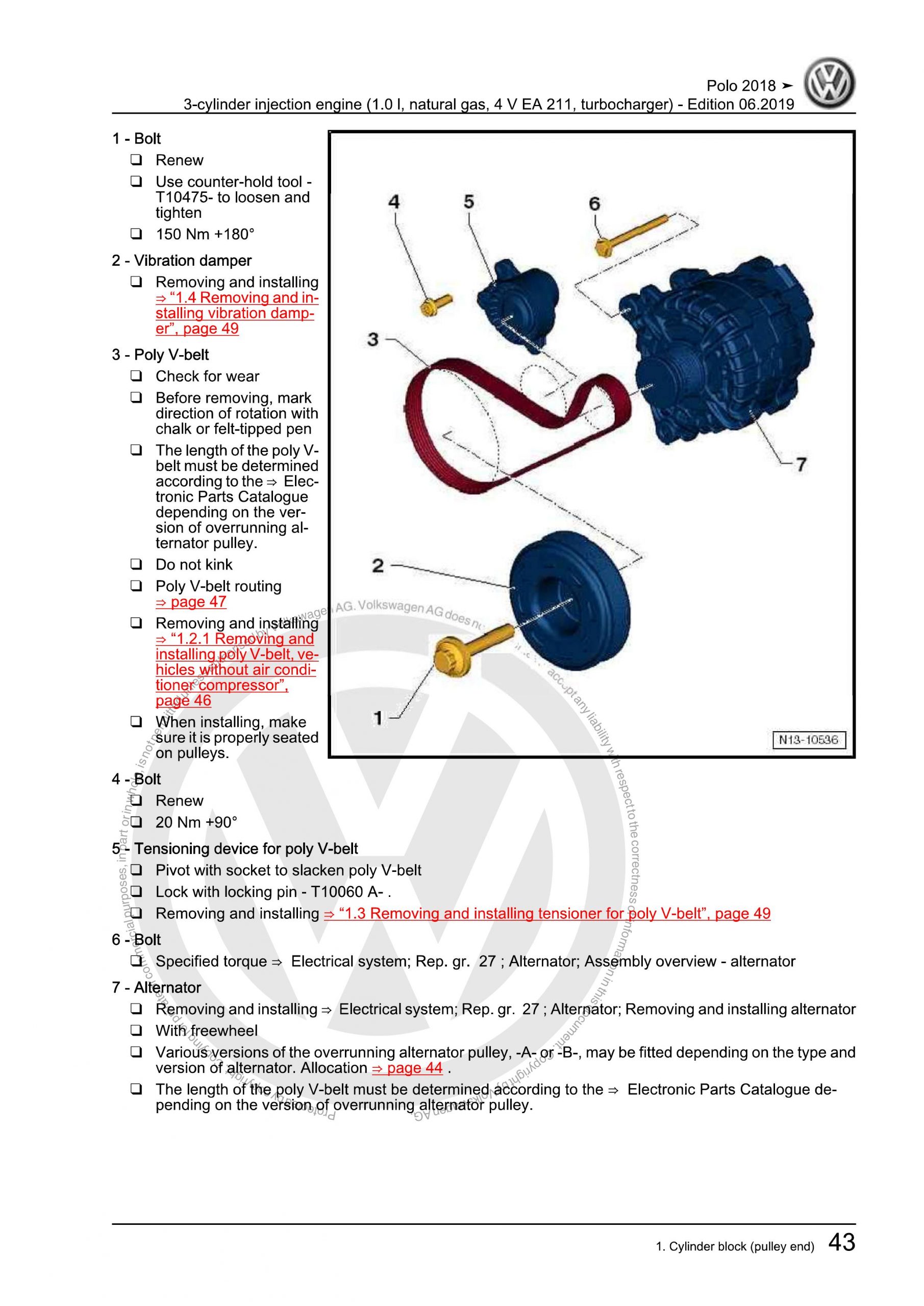

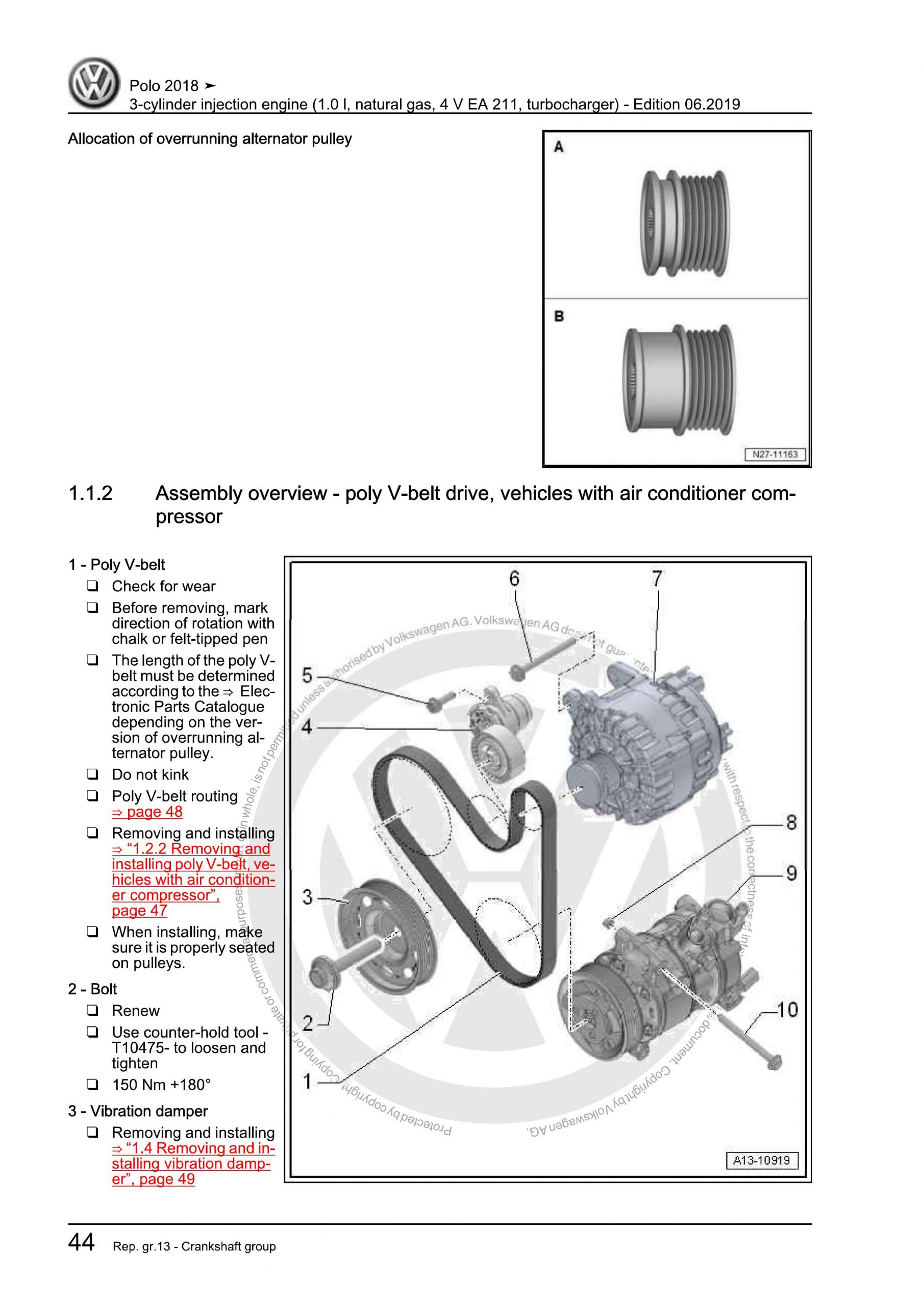

- Cylinder block (pulley end)

- Assembly overview – poly V-belt drive

- Removing and installing poly-V belt

- Removing and installing tensioner for poly V-belt

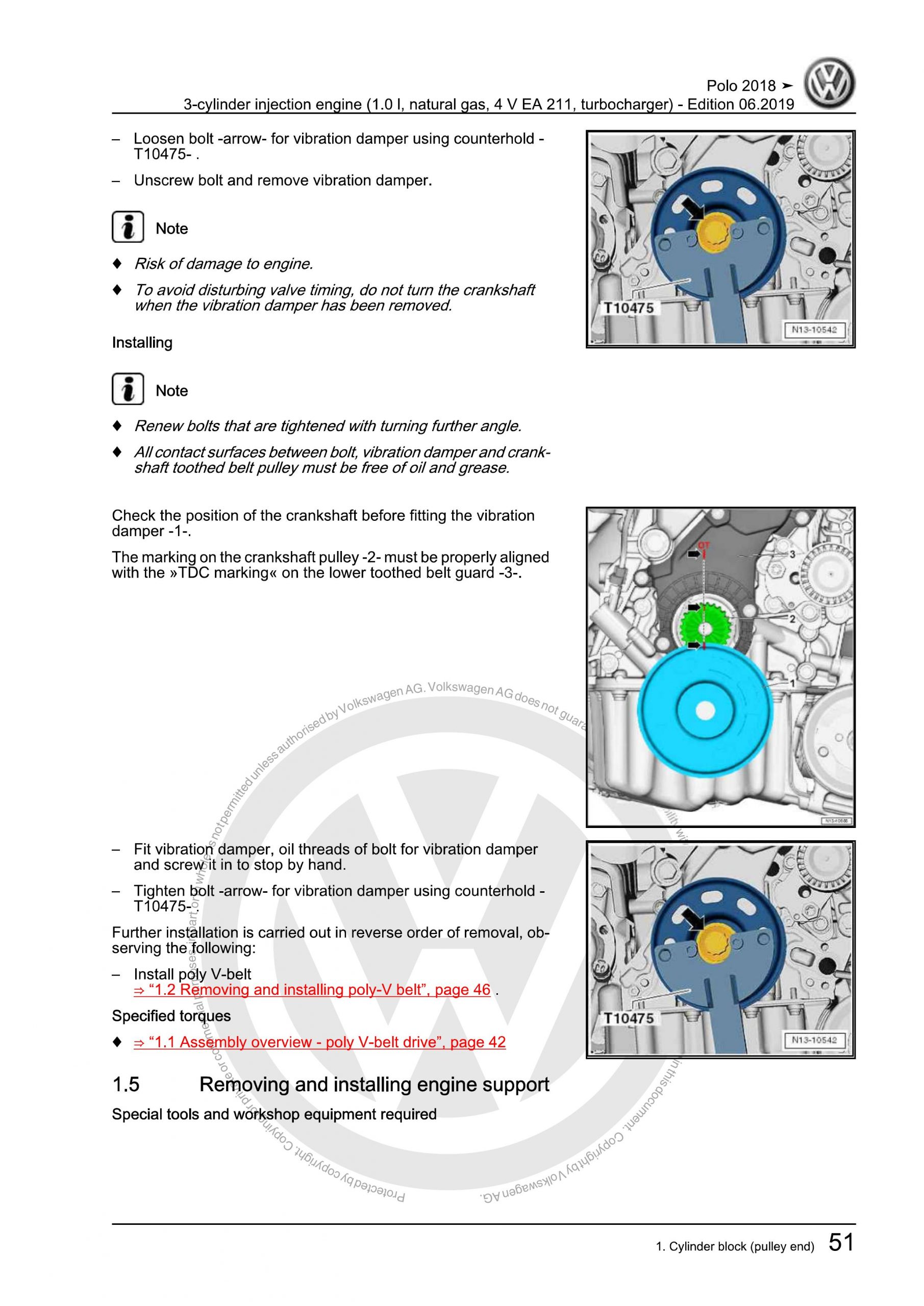

- Removing and installing vibration damper

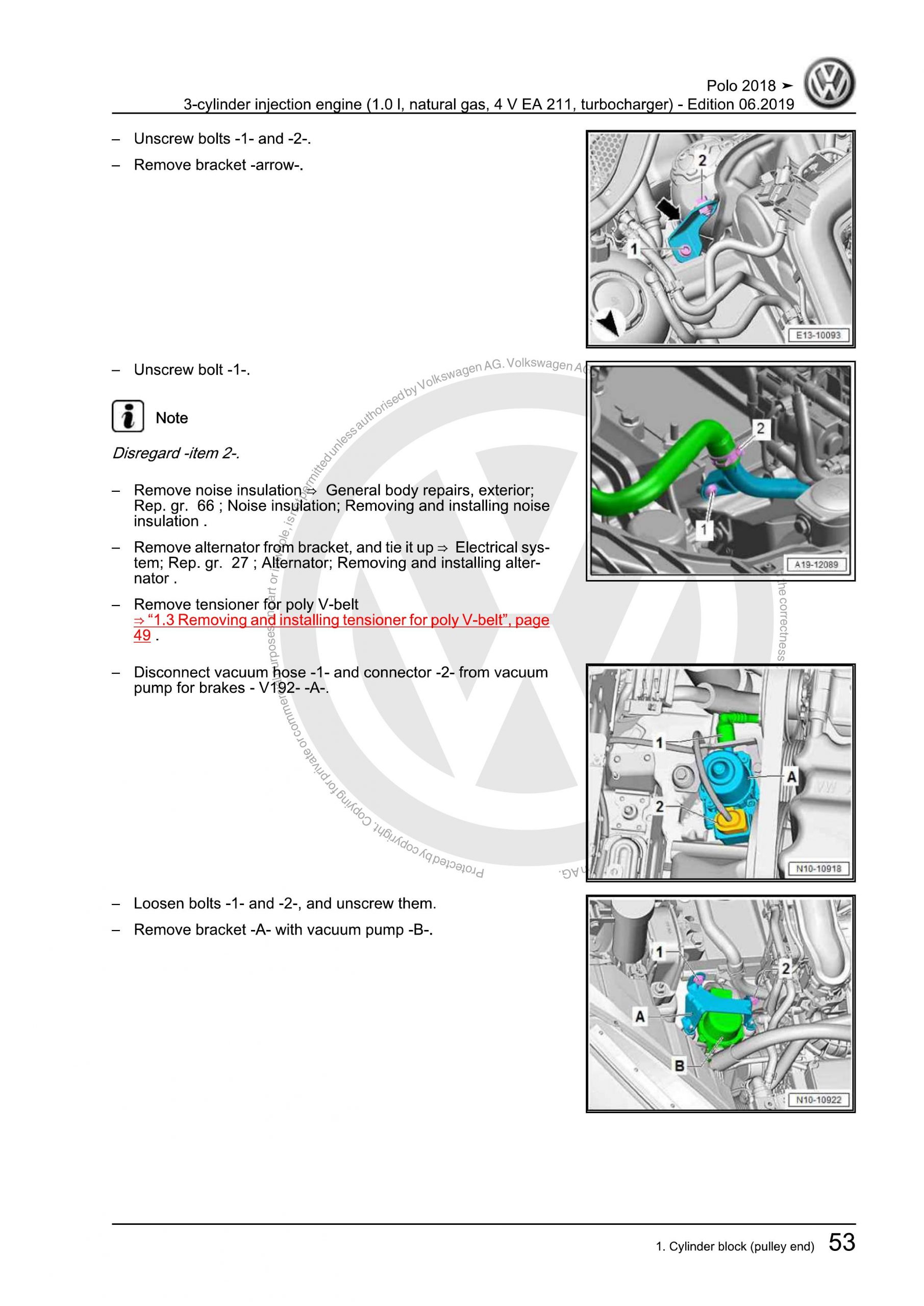

- Removing and installing engine support

- Renewing crankshaft oil seal – belt pulley end

- Cylinder block, gearbox end

- Assembly overview – cylinder block, gearbox end

- Removing and installing flywheel

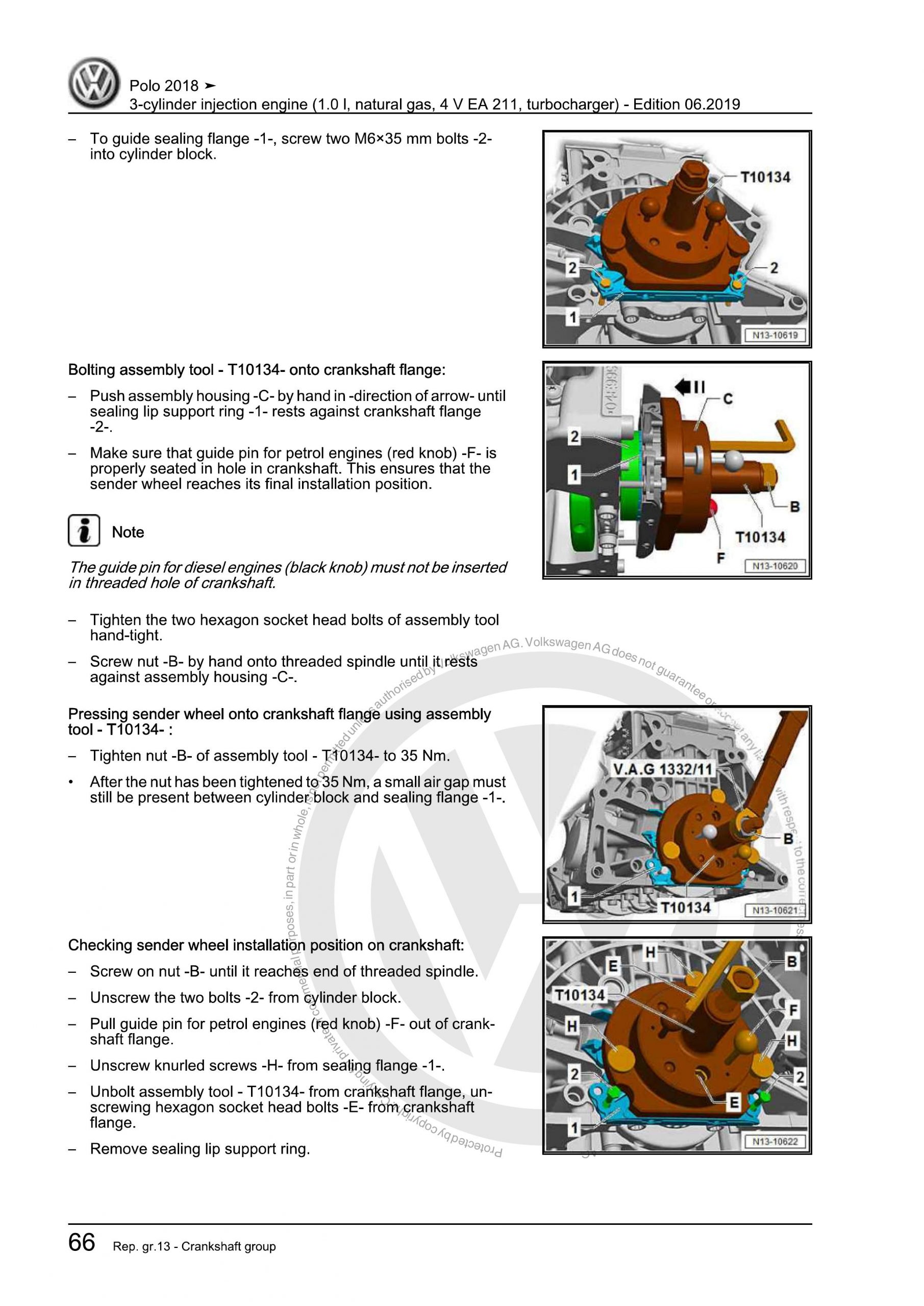

- Removing and installing sealing flange on gearbox side

- Crankshaft

- Crankshaft dimensions

- Measuring axial clearance of crankshaft

- Pistons and conrods

- Assembly overview – pistons and conrods

- Removing and installing pistons

- Checking pistons and cylinder bores

- Separating new conrod

- Checking radial clearance of conrods

- Removing and installing oil spray jets

- Setting piston to TDC position

- Cylinder head, valve gear

- Cylinder head

- Assembly overview – cylinder head

- Assembly overview – camshaft housing

- Removing and installing cylinder head

- Removing and installing camshaft housing

- Checking compression

- Toothed belt drive

- Assembly overview – toothed belt cover

- Assembly overview – toothed belt

- Removing and installing toothed belt guard

- Preassembling and installing test tool VAS 611 007

- Checking valve timing

- Adjusting valve timing

- Removing toothed belt from camshaft

- Removing and installing toothed belt

- Valve gear

- Assembly overview – valve gear

- Removing and installing camshaft adjuster

- Measuring axial play of camshaft

- Removing and installing camshaft oil seal

- Removing and installing camshaft control valve 1 N205

- Removing and installing exhaust camshaft control valve 1 N318

- Removing and installing valve stem seals

- Inlet and exhaust valves

- Checking valve guides

- Checking valves

- Valve dimensions

- Lubrication

- Sump, oil pump

- Assembly overview – sump/oil pump

- Engine oil:

- Removing and installing sump

- Removing and installing oil level and oil temperature sender G266

- Removing and installing oil pump

- Engine oil cooler

- Assembly overview – engine oil cooler

- Removing and installing engine oil cooler

- Crankcase ventilation

- Assembly overview – crankcase breather system

- Removing and installing oil separator

- Oil filter, oil pressure switch

- Assembly overview – oil filter/oil pressure switch

- Removing and installing oil filter housing

- Removing and installing oil pressure sender G10

- Removing and installing oil pressure regulating valve N428

- Checking oil pressure

- Cooling

- Cooling system/coolant

- Connection diagram – coolant hoses

- Draining and adding coolant

- Checking cooling system for leaks

- Coolant pump, regulation of cooling system

- Assembly overview – coolant pump, thermostat

- Assembly overview – electric coolant pump

- Assembly overview – coolant temperature sender

- Removing and installing coolant pump

- Removing and installing toothed belt pulley for coolant pump

- Removing and installing thermostat

- Removing and installing electric coolant pump

- Removing and installing coolant temperature sender G62

- Removing and installing radiator outlet coolant temperature sender G83

- Coolant pipes

- Assembly overview – coolant pipes

- Removing and installing coolant pipes

- Radiator, radiator fan

- Assembly overview – radiator/radiator fan

- Assembly overview – radiator cowl and radiator fan

- Removing and installing radiator

- Removing and installing radiator cowl

- Removing and installing radiator fan V7

- Turbocharging/supercharging

- Turbocharger

- Assembly overview – turbocharger

- Removing and installing turbocharger

- Removing and installing charge pressure positioner V465

- Removing and installing connection for turbocharger

- Charge air system

- Assembly overview – charge air system

- Removing and installing air pipe

- Removing and installing charge pressure sender GX26

- Removing and installing charge air cooler

- Checking charge air system for leaks

- Mixture preparation – injection

- Injection system

- Overview of fitting locations – injection system

- Air filter

- Assembly overview – air filter housing

- Removing and installing air filter housing

- Intake manifold

- Assembly overview – intake manifold

- Removing and installing intake manifold

- Removing and installing throttle valve module GX3

- Cleaning throttle valve module GX3

- Checking natural gas supply system for leaks

- Distinguishing between pressure sections of natural gas supply system

- Determining pressure in gas system

- Determining operating mode of natural gas vehicles

- Activating and deactivating natural gas mode

- Checking gas system for leaks

- Gas pressure regulator

- Assembly overview – gas pressure regulator

- Removing and installing gas pressure regulator

- Removing and installing tank pressure sensor G400

- Gas injectors

- Assembly overview – gas rail

- Removing and installing gas rail with gas injector N366 / N367 / N368

- Removing and installing gas rail temperature and pressure sensor GX21

- Injectors

- Assembly overview – fuel rail with injectors

- Removing and installing fuel rail

- Removing and installing injectors

- Cleaning injectors

- Senders and sensors

- Removing and installing intake manifold sender GX9

- Removing and installing fuel pressure sender G247

- Checking fuel pressure sender G247

- High-pressure pump

- Assembly overview – high-pressure pump

- Removing and installing high-pressure pump

- Removing and installing high-pressure pipe

- Lambda probe

- Assembly overview – Lambda probe

- Removing and installing Lambda probe

- Engine control unit

- Removing and installing engine (motor) control unit J623

- Exhaust system

- Exhaust pipes and silencers

- Assembly overview – silencers

- Removing and installing silencer

- Aligning exhaust system free of stress

- Checking exhaust system for leaks

- Emission control

- Assembly overview – emission control

- Removing and installing catalytic converter

- Ignition system

- Ignition system

- Assembly overview – ignition system

- Removing and installing ignition coils with output stage

- Removing and installing knock sensor 1 G61

- Removing and installing Hall sender G40

- Removing and installing engine speed sender G28

Abrites AVDI J2534

Abrites AVDI J2534 Actia Multi-Diag

Actia Multi-Diag Autoland iSCAN

Autoland iSCAN BMW ENET

BMW ENET Bosch Mastertech II J2534

Bosch Mastertech II J2534 Bosch MTS 6531

Bosch MTS 6531 CAN CLIP RLT2002

CAN CLIP RLT2002 CarDAQ-Plus 3

CarDAQ-Plus 3 Cummins INLINE Datalink

Cummins INLINE Datalink Dearborn Protocol Adapter (DPA) 5

Dearborn Protocol Adapter (DPA) 5 Delphi/Autocom DS150E

Delphi/Autocom DS150E Volvo VIDA DiCE

Volvo VIDA DiCE Derelek USB DIAG 3

Derelek USB DIAG 3 Electronic Data Link (EDL) 2

Electronic Data Link (EDL) 2 Electronic Data Link (EDL) 3

Electronic Data Link (EDL) 3 GM MDI 1

GM MDI 1 GM MDI 2

GM MDI 2 HEX-V2 VCDS VAG-COM

HEX-V2 VCDS VAG-COM Isuzu IDSS IDS MX1

Isuzu IDSS IDS MX1 Isuzu IDSS IDS MX2

Isuzu IDSS IDS MX2 Iveco Eltrac E.A.SY. ECI

Iveco Eltrac E.A.SY. ECI MaxiFlash Elite J2534

MaxiFlash Elite J2534 Mongoose J2534

Mongoose J2534 Nexiq USB-Link 1

Nexiq USB-Link 1 Nexiq USB-Link 2

Nexiq USB-Link 2 Nexiq USB-Link 3

Nexiq USB-Link 3 Noregon DLA+ 2.0

Noregon DLA+ 2.0 Porsche PIWIS TESTER 3 (PT3G)

Porsche PIWIS TESTER 3 (PT3G) PSA LEXIA 3

PSA LEXIA 3 SAE J2434

SAE J2434 Scania VCI 3

Scania VCI 3 Scanmatik 2 PRO

Scanmatik 2 PRO SD Connect Multiplexer

SD Connect Multiplexer Tactrix OpenPort 2.0

Tactrix OpenPort 2.0 Toyota TIS Mini VCI

Toyota TIS Mini VCI VAG ODIS VAS5054 Clone

VAG ODIS VAS5054 Clone VAG ODIS VAS6154 Clone

VAG ODIS VAS6154 Clone Volvo VOCOM 1

Volvo VOCOM 1 Volvo VOCOM 2

Volvo VOCOM 2

Reviews

Clear filtersThere are no reviews yet.